Three-dimensional laser scanning calibration method simultaneously constrained by point and surface characteristics

A three-dimensional laser and surface feature technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of consuming manpower and material resources, lack of angle or orientation constraints, and less joint adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The embodiments of the present invention are described in further detail below, but the embodiments are not limited to the present invention, and all similar methods and similar changes of the present invention should be included in the protection scope of the present invention.

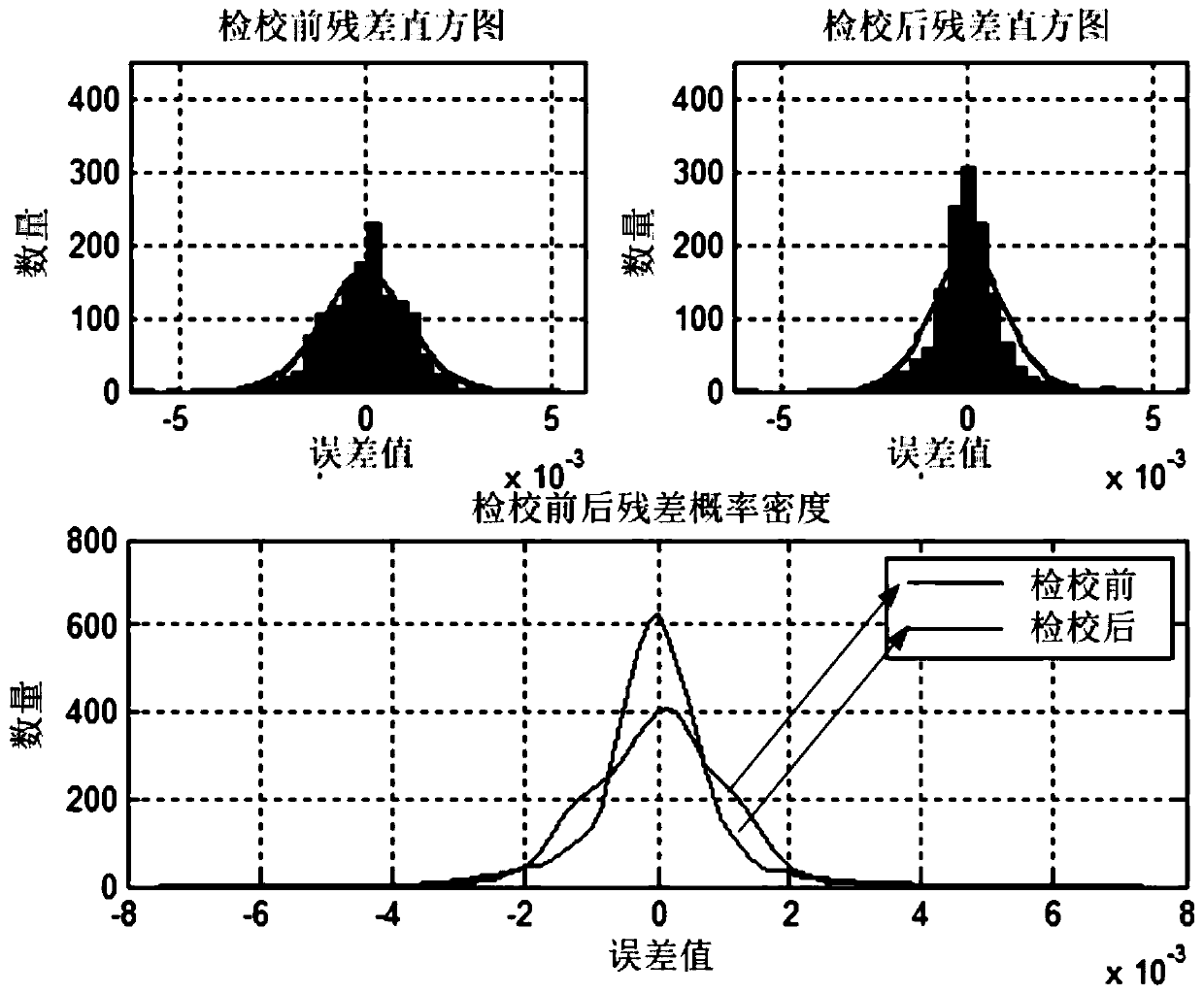

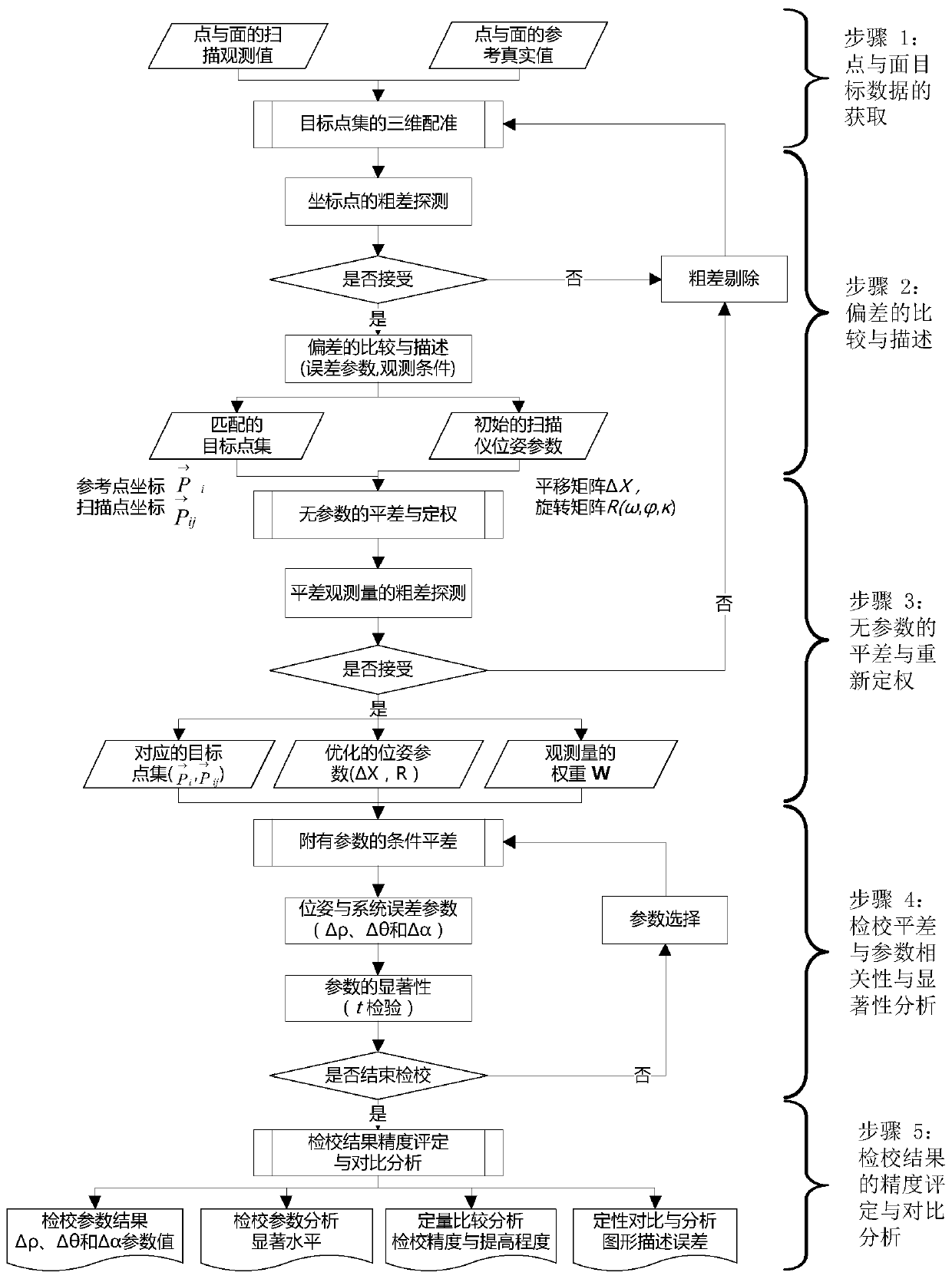

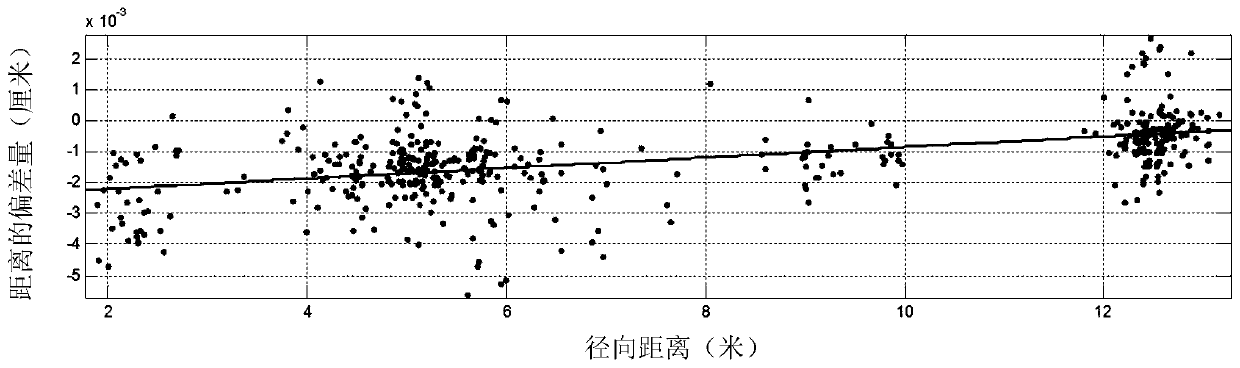

[0047] (1) Simultaneously obtain the scanning observation values and reference real values of point and surface characteristic targets, and perform three-dimensional registration of target point sets and gross error detection of coordinate points; simultaneously arrange characteristic targets of point and surface targets in the laboratory, and establish a The indoor comprehensive calibration field of the 3D laser scanner, where the point-shaped target adopts a standard ball with a diameter of 10cm, the laser-printed black background and white circle marks with a diameter of 14cm and 5cm, and black and white diagonally distributed marks. Off-white planed wood boards with a width of 1.0m and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com