Method and device for controlling parallelism of thin film in imprinting equipment

A technology of embossing equipment and a control method, which is applied in the field of thin film parallelism control and thin film parallelism control devices in embossing equipment, can solve the problem of low stability of thin film parallelism control, achieve the goal of eliminating cumulative errors and improving stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following content is an example of the specific implementation process provided for the technical solution to be protected in this application in detail, but this application can also be implemented in other ways than the description here, and those skilled in the art can follow the guidelines of this application. Below, different technical means are used to realize the present application, so the present application is not limited by the following specific examples.

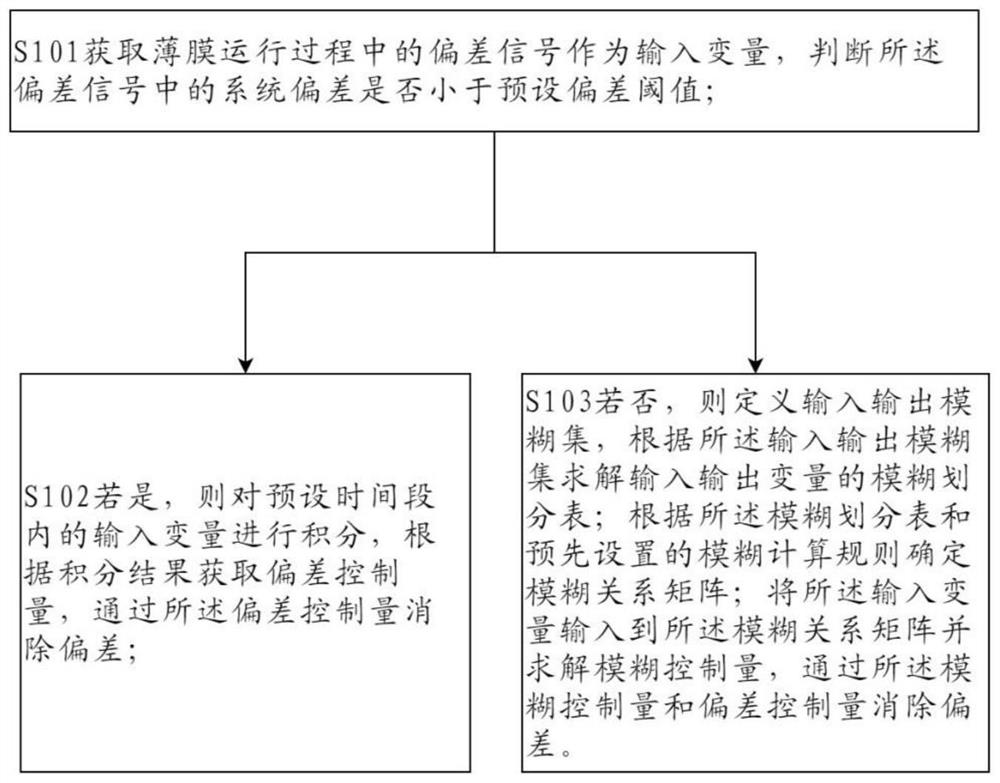

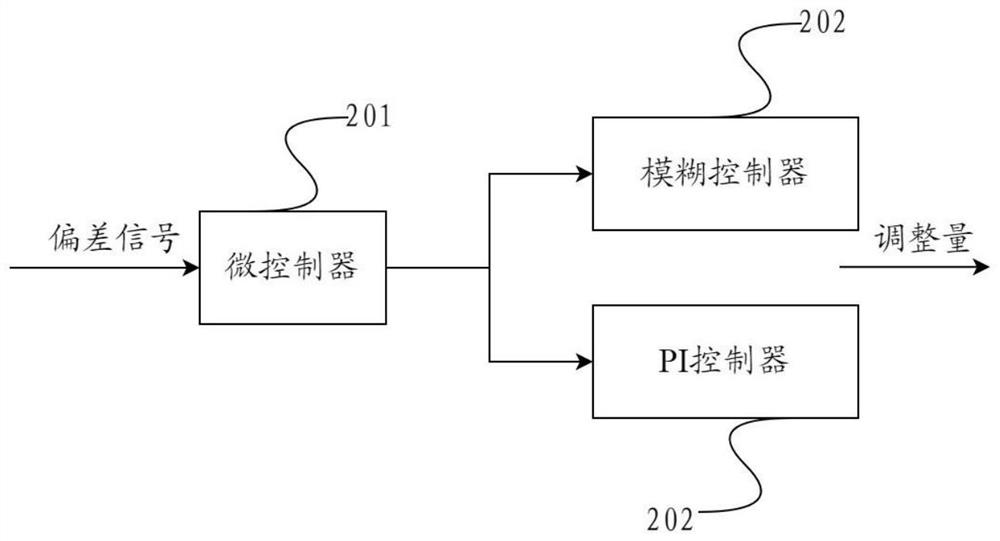

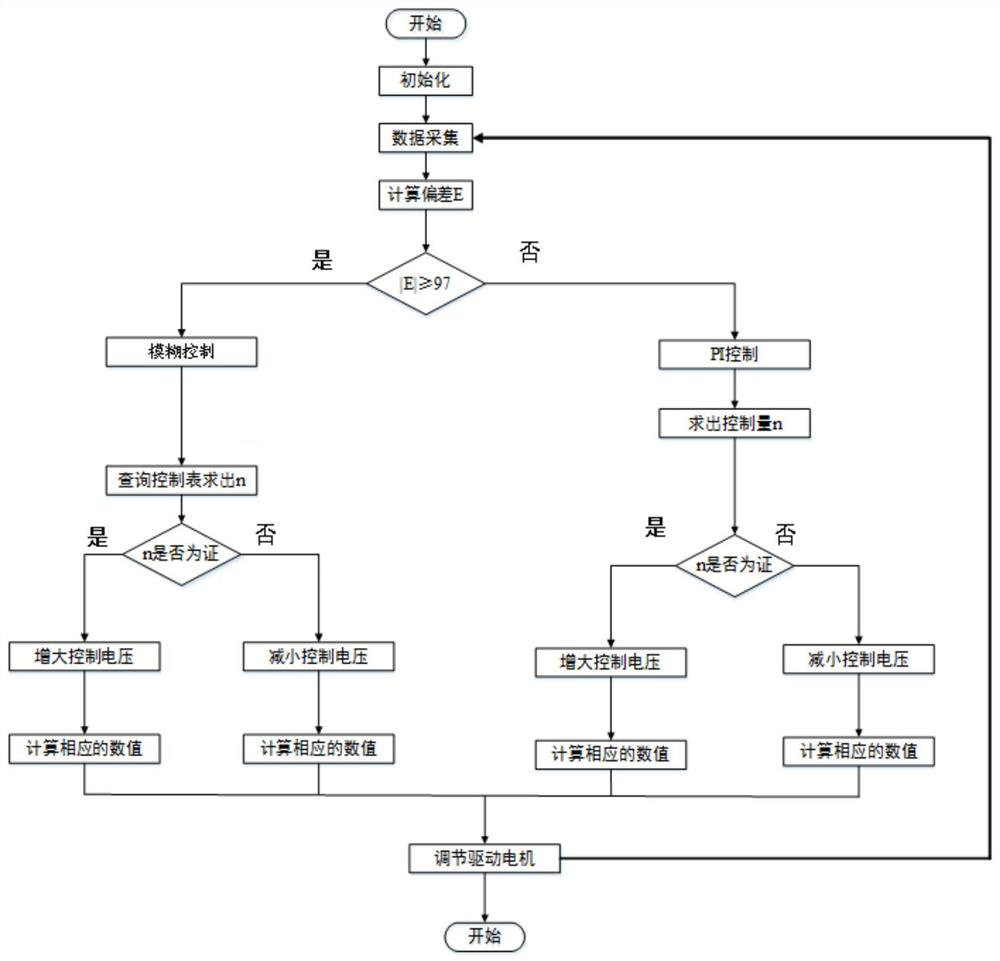

[0045] A method for controlling the parallelism of a thin film in an imprinting device provided by the present application includes: obtaining a deviation signal during the operation of the thin film as an input variable, and judging whether the systematic deviation in the deviation signal is less than a preset deviation threshold; Integrate the input variable within the preset time period, obtain the deviation control amount according to the integration result, and eliminate the deviation through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com