Radian testing device for battery diaphragm

A battery diaphragm, radian measurement technology, applied in mechanical counter/curvature measurement and other directions, can solve the problems of uncontrollable tension, large measurement error, large test system error, etc., to improve test accuracy, improve measurement efficiency, and small system deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

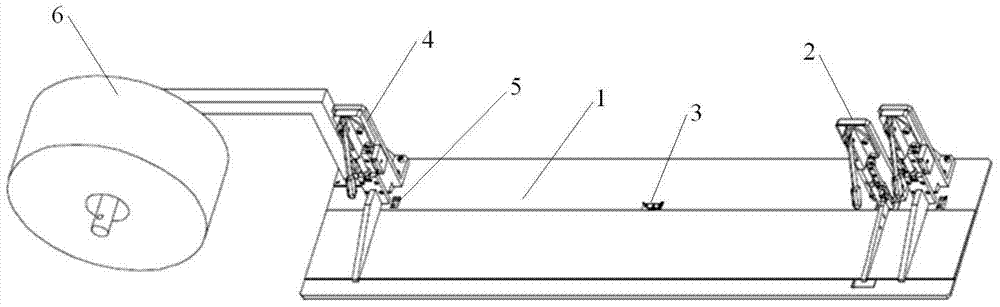

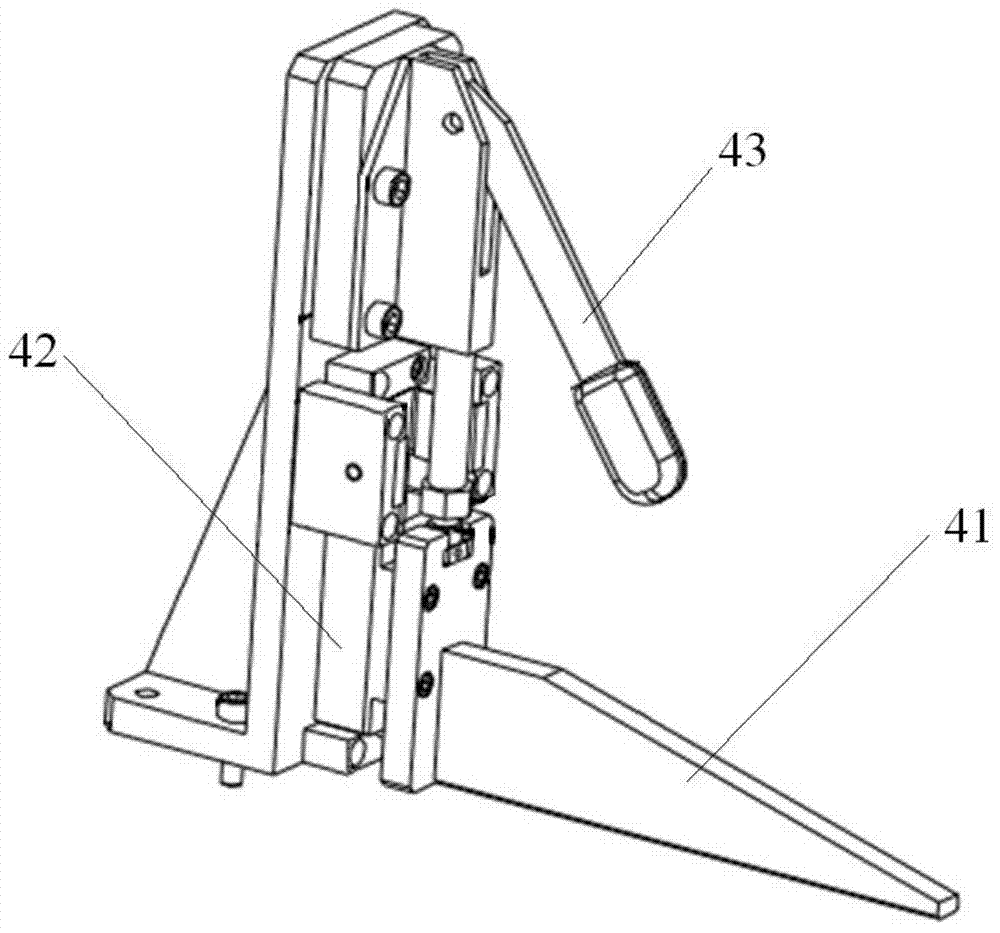

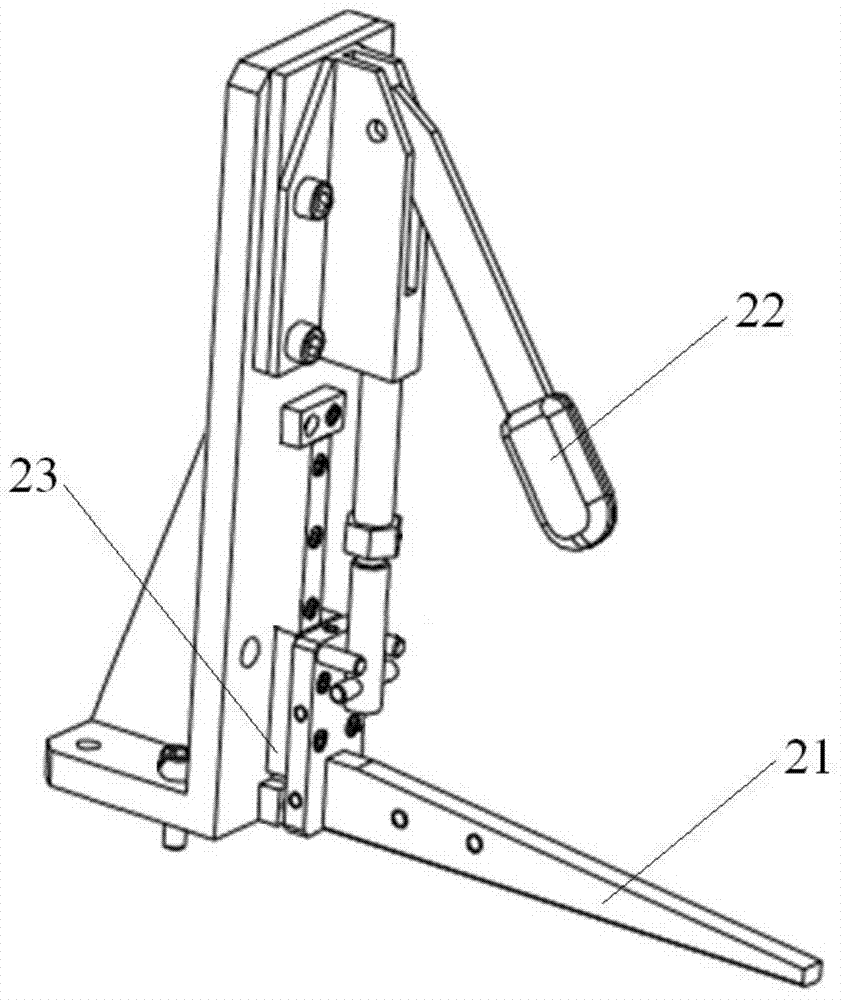

[0029] The device used for testing the curvature of the battery diaphragm in this example, such as Figure 1-Figure 5 As shown, it includes a test bench 1, a tension mechanism 2, a radian measuring scale 3, two sets of pressing mechanisms 4 and two positioning blocks 5. Among them, the test bench 1 is a stainless steel plate with a surface roughness less than 1.6 after horizontal calibration; each set of pressing mechanism 4 includes a pressing part 41 and a pressing part movable rail 42, and the pressing part 41 is movably assembled on the pressing part On the movable rail 42, it can move up and down along the movable rail 42 of the pressing part; two sets of pressing mechanisms are respectively installed on both ends of the test bench 1, and the movable rail 42 of the pressing part is erected and vertically assembled on the test bench 1, and the pressing part 41 is located on the Directly above the test bench 1, parallel to the width side of the test bench, the test bench 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com