vacuum packaging machine

A vacuum packaging machine, vacuum technology, applied in packaging, packaging under vacuum/special atmosphere, transportation packaging, etc., can solve the problems of unreasonable structure, low production efficiency, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

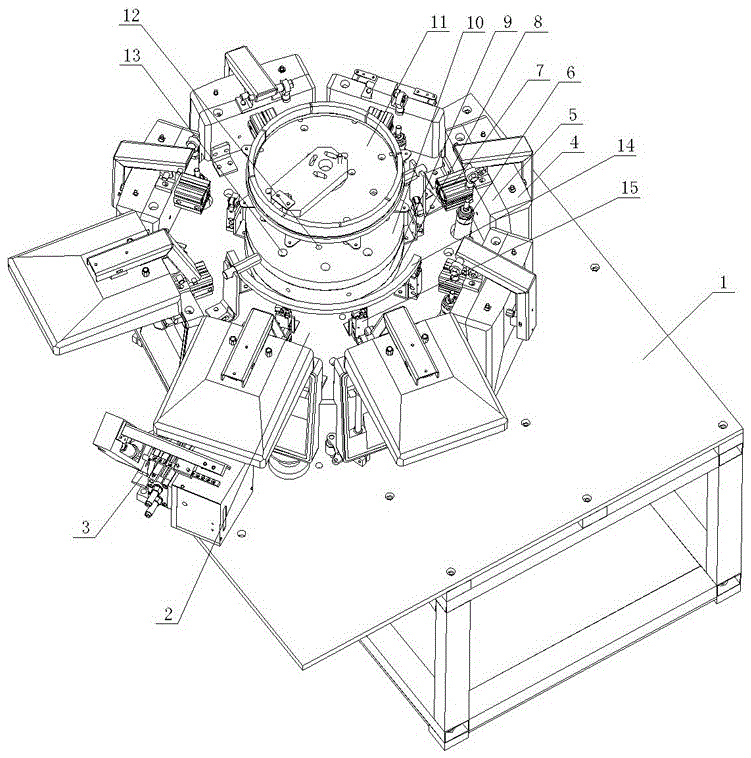

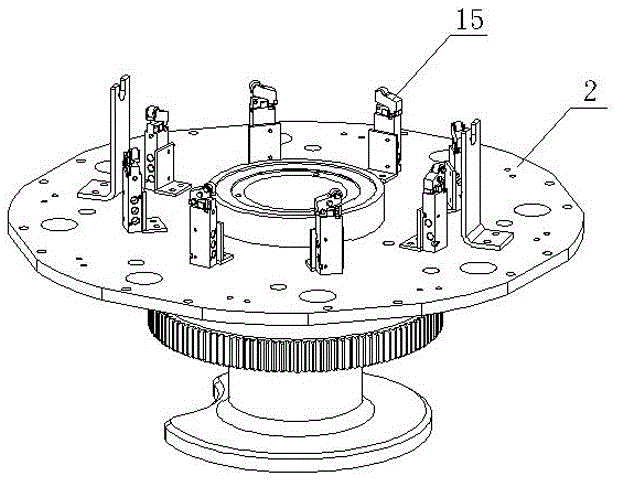

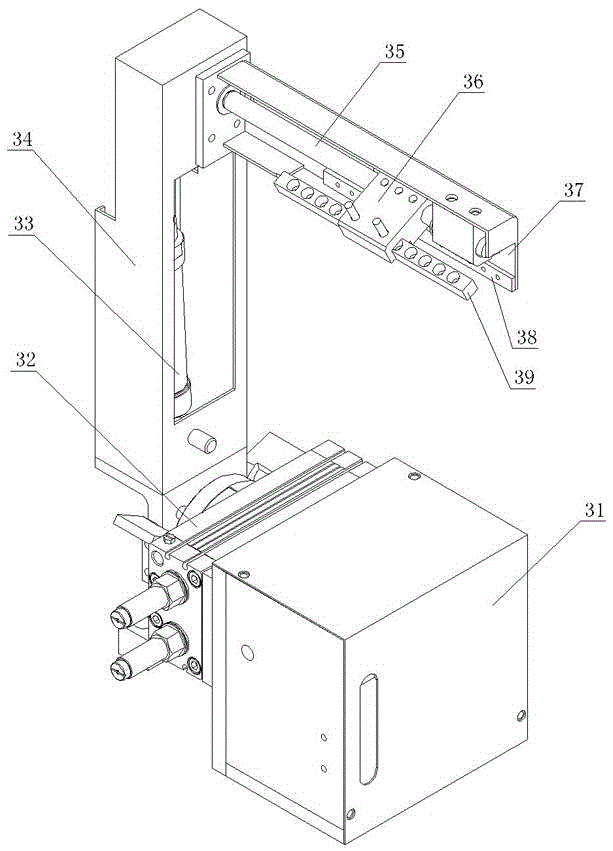

[0034] As shown in the figure, the vacuum packaging machine of the present invention includes a fixed workbench 1, on which a turntable 2 is rotated, and the turntable 2 is driven by a servo motor, and eight vacuum chamber units are evenly arranged on the outer circumference of the turntable 2. Corresponding to the bagging, closing, vacuum 1, vacuum 2, heat sealing, cooling, exhaust and cover opening stations of the workbench 1 respectively, at the bagging station, the workbench 1 is provided with a corresponding bagging mechanism 3, said The vacuum chamber unit has a vacuum chamber 5 with an upper flap door 4, a heat-sealing assembly and a bag clip assembly located in the vacuum chamber 5, the vacuum chamber 5 is fixed on the rotating disk 2, and the opening and closing of the lid door 4 is controlled by the The cover-opening cylinder 6 on the back of the vacuum chamber 5 is pushed, and the heat-sealing cylinder 7 of the heat-sealing assembly is fixedly installed on the back o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com