Waterproof and moisture permeable grid printed fabric and preparation method thereof

A waterproof, moisture-permeable and printing technology, which is applied in the fields of dyeing, plant fibers, textiles, and papermaking, and can solve the problems of few studies on functional printing of waterproof and moisture-permeable fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

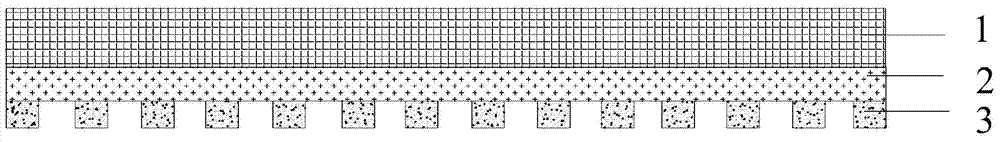

[0085] Such as figure 1 As shown, a waterproof and moisture-permeable grille printed fabric is composed of a base fabric 1, a waterproof moisture-permeable layer 2 and a printed pattern layer 3 in turn. The printed texture of the printed pattern layer 3 and the waterproof moisture-permeable layer 2 are formed A grid-shaped diversion groove, wherein the waterproof and moisture-permeable layer 2 is a hydrophobic waterproof and moisture-permeable layer, and the printed pattern layer 3 is a hydrophilic printed pattern layer.

specific Embodiment approach 2

[0086] The structure of the waterproof and moisture-permeable grid printed fabric is the same as that of Embodiment 1, except that the waterproof and moisture-permeable layer 2 is a hydrophilic waterproof and moisture-permeable layer, and the printed pattern layer 3 is a hydrophobic printed pattern layer.

Embodiment 1

[0088] 1. Base fabric selection: 20D, 400T lattice nylon spinning, waterproof effect is above level 4.

[0089] 2. The waterproof and moisture-permeable layer is made by coating aliphatic polyether polyurethane moisture-permeable coating glue, and the polyurethane moisture-permeable coating glue is composed of a primer, a middle layer and a surface layer.

[0090] The primer includes in parts by weight:

[0091]

[0092] Adjust the viscosity of the primer by adding solvents such as toluene, methyl ethyl ketone and ethyl acetate.

[0093] The middle layer glue includes in parts by weight:

[0094] Polyurethane coating glue FS-5811 100

[0095] Polyurethane white paint FS-5822A 30.

[0096] The viscosity of the middle layer glue is 7000-10000 cps.

[0097] Adjust the viscosity of the middle layer glue by adding solvents such as toluene and methyl ethyl ketone.

[0098] The surface layer glue includes in parts by weight:

[0099]

[0100] Adjust the viscosity of the surface layer glue by adding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com