A waterproof and moisture-permeable grid printed fabric and its preparation method

A waterproof and moisture-permeable, printing technology, applied in the direction of dyeing, plant fibers, textiles and papermaking, etc., can solve problems such as the lack of research on functional printing of waterproof and moisture-permeable fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

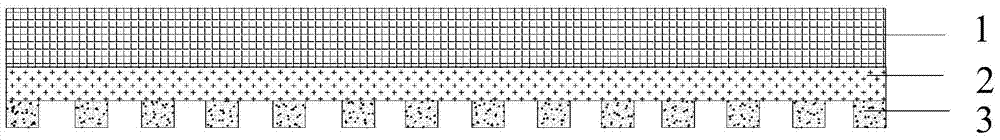

[0085] Such as figure 1 As shown, a waterproof and moisture-permeable grille printed fabric, the fabric is sequentially composed of a base fabric 1, a waterproof and moisture-permeable layer 2, and a printed pattern layer 3, and the printed texture of the printed pattern layer 3 is formed by the waterproof and moisture-permeable layer 2 A grid-shaped diversion groove, wherein the waterproof and moisture-permeable layer 2 is a hydrophobic waterproof and moisture-permeable layer, and the printed pattern layer 3 is a hydrophilic printed pattern layer.

specific Embodiment approach 2

[0086] The structure of the waterproof and moisture-permeable grid printed fabric is the same as that in Embodiment 1, except that the waterproof and moisture-permeable layer 2 is a hydrophilic waterproof and moisture-permeable layer, and the printed pattern layer 3 is a hydrophobic printed pattern layer.

Embodiment 1

[0088] 1. Base fabric selection: 20D, 400T lattice nylon fabric, waterproof effect above grade 4.

[0089] 2. The waterproof and moisture-permeable layer is prepared by coating an aliphatic polyether polyurethane moisture-permeable coating glue, and the polyurethane moisture-permeable coating glue is composed of a primer, a middle glue and a surface glue.

[0090] Described primer comprises by weight parts:

[0091]

[0092] Adjust the viscosity of the primer by adding solvents such as toluene, methyl ethyl ketone and ethyl acetate.

[0093] Described middle glue comprises by weight parts:

[0094] Polyurethane coating glue FS-5811 100

[0095] Polyurethane white paint FS-5822A 30.

[0096] The viscosity of the middle glue is 7000-10000 cps.

[0097] Adjust the viscosity of the middle layer glue by adding solvents such as toluene and butanone.

[0098] Described surface glue comprises by weight parts:

[0099]

[0100] Adjust the viscosity of the top coat by adding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com