Pull-out Chassis Brackets for Cabinets

A bracket device and pull-out technology, which is applied in the direction of support structure installation, etc., can solve the problem that the chassis cannot be pulled out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

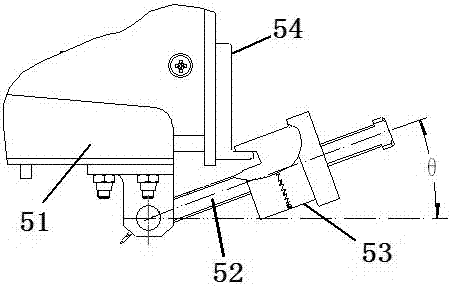

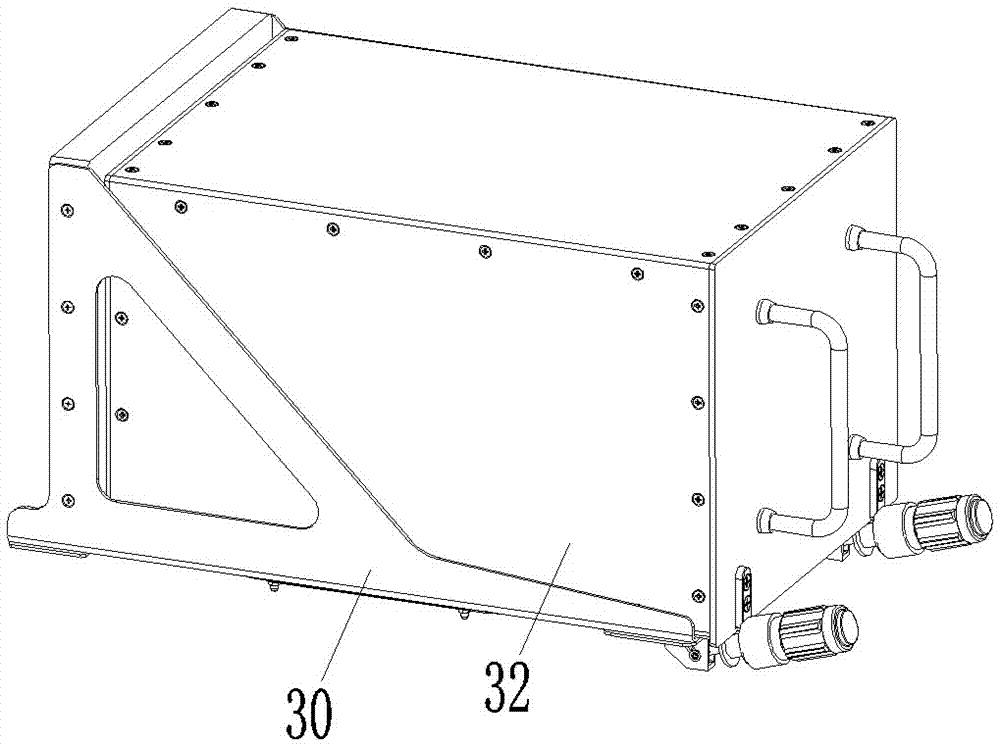

[0023] An embodiment of a chassis bracket device for a cabinet, such as Figure 2-12 As shown, the chassis bracket device includes a bracket 30 and a locking device.

[0024] The structure of the bracket is the prior art, and will not be described in detail here, and the locking device is assembled on the front part of the bracket.

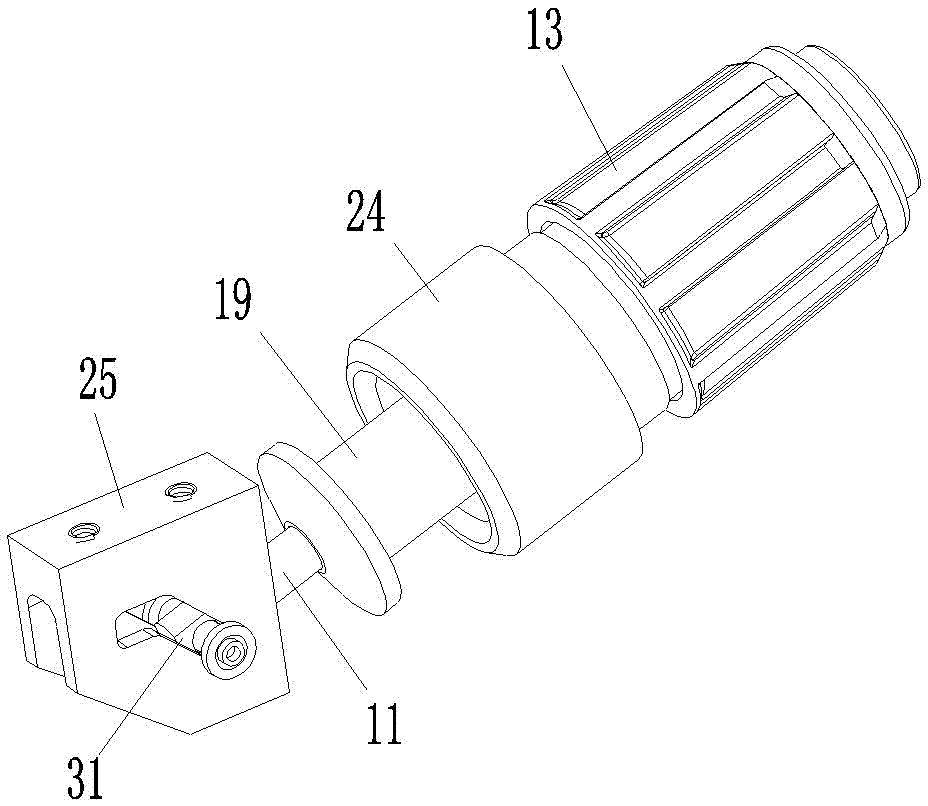

[0025] The locking device includes a locking rod 11, a screw sleeve 12, a screw cap 13, a transmission steel ball 14, a transmission plate 15, a pressure plate 16, a force limiting spring 17, a spring support sleeve 18, an output sleeve 19, a transmission seat 20, a ball 21, Push spring 22, transmission sleeve 23, lock cap 24 and lock seat 25.

[0026] The front end of the locking rod 11 is provided with a hinge hole and a threaded section is provided between the two ends.

[0027] The position between the two ends of the screw sleeve 12 is provided with an internal thread segment, which corresponds to the thread segment on the lock bar 11, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com