Wick holder and method for the production thereof

A technology for holding parts and candle wicks, which is applied in the direction of candle wicks, burning methods, candle preparation devices, etc., and can solve the problems of expensive candle wick holding parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

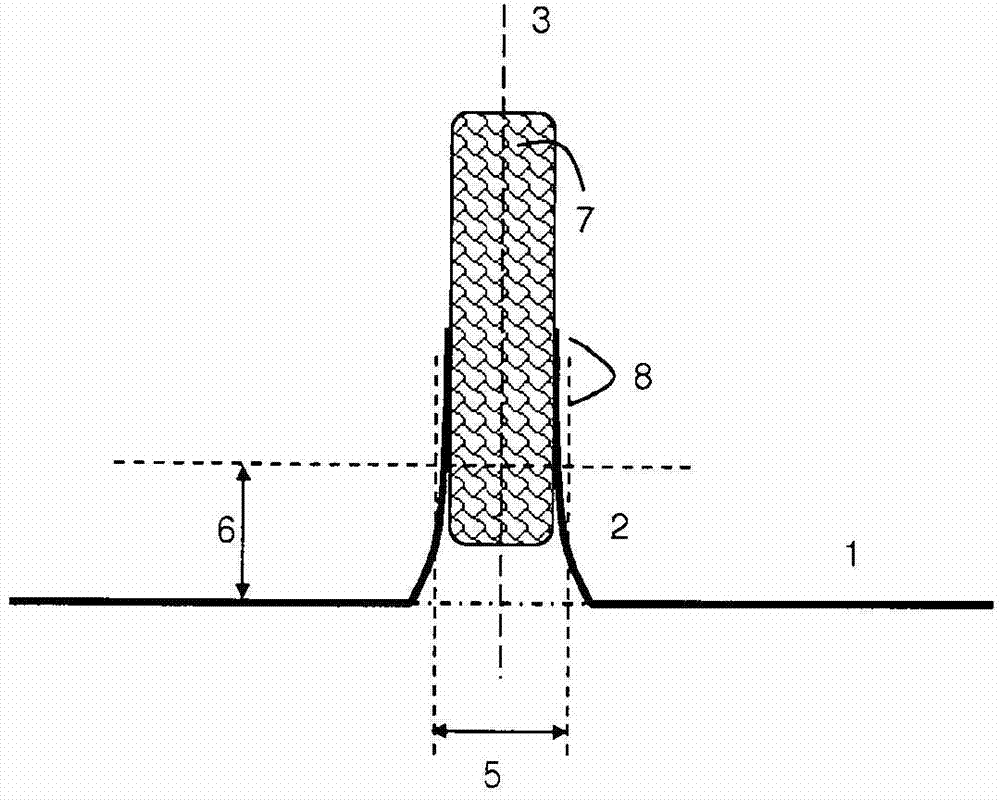

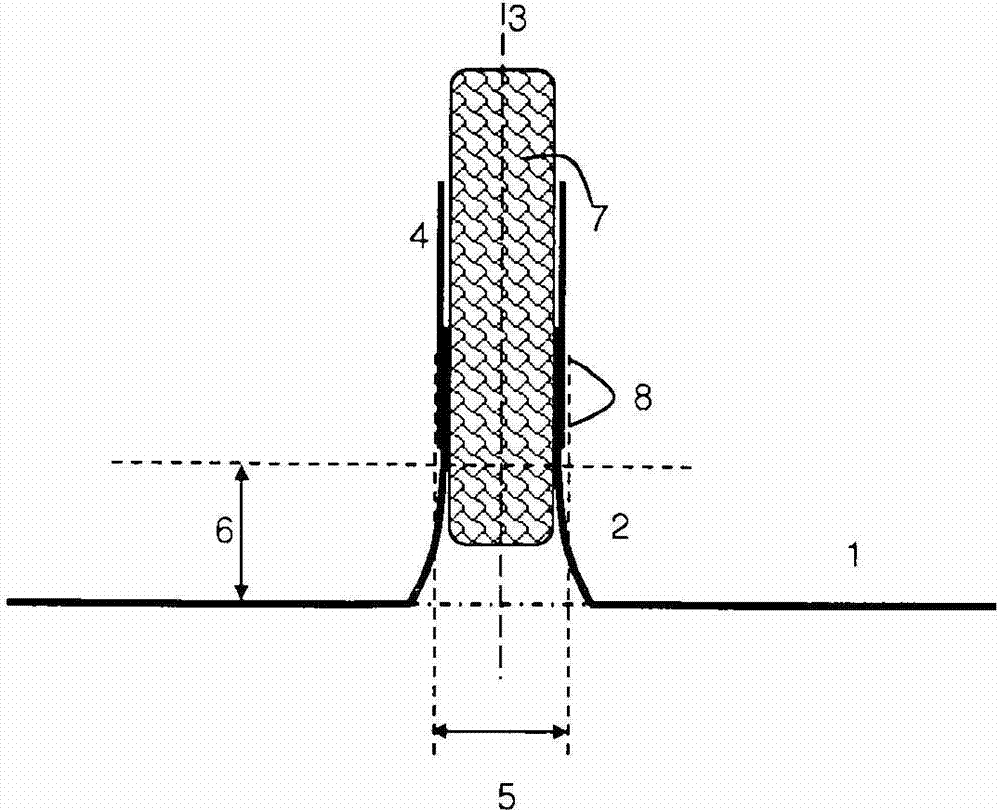

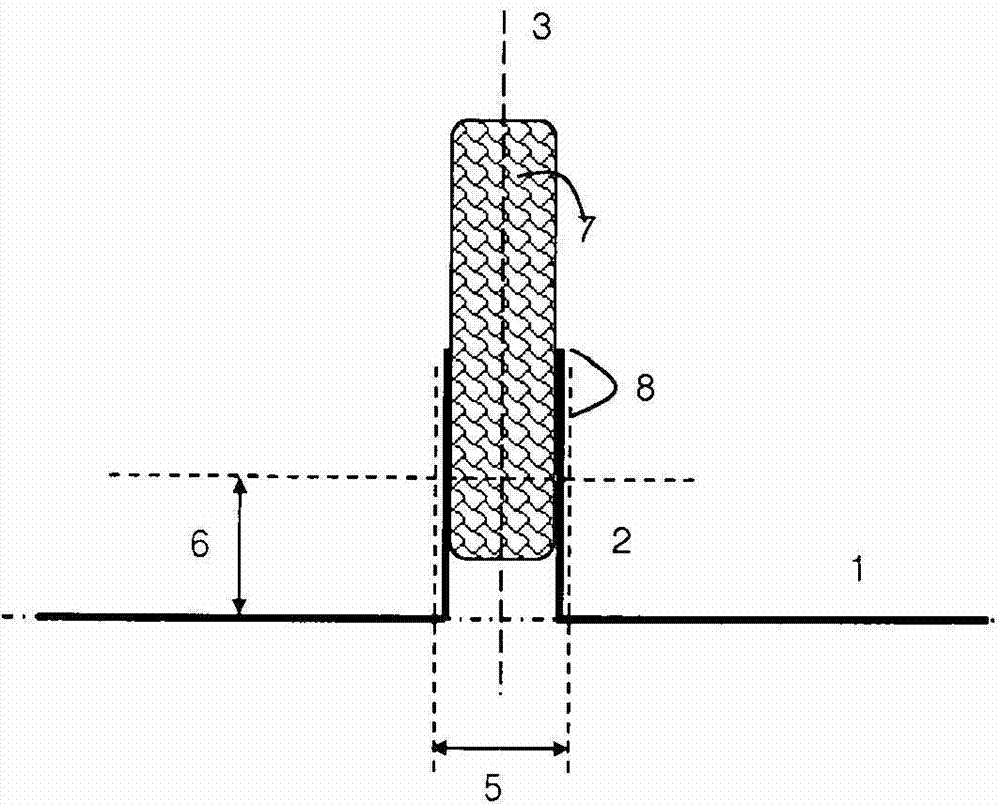

[0045] According to the invention, a wick holder is provided which comprises a base plate 1 with a central channel in the form of a hollow cylindrical projection 2 (neck). The cylinder axis 3 of the hollow cylindrical protrusion is perpendicular to the base plate 1 . Known wick holders also have these features of the wick holder according to the invention, which are used as a starting point for the production of the wick holder according to the invention. Unlike known wick holders ( figure 1 , 3 and 5), in the wick holder by the present invention ( figure 2 , 4 In and 6), the hollow cylindrical extension 4 (extension piece) is installed on the hollow cylindrical protrusion 2, so that the cylinder axis 3 of the hollow cylindrical protrusion and the hollow cylindrical extension coincide.

[0046] In addition to the supporting function of the neck 2 , the candle wick 7 is also supported by this extension 4 . Furthermore, if the wick 7 burns to the upper edge of the extensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com