Composite anti-blocking suction pipe

A composite, straw technology, used in table utensils, home utensils, table utensils, etc., can solve the problems that consumers are difficult to absorb liquid, and it is difficult to absorb liquid, so as to avoid pressure difference and absorb liquid smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

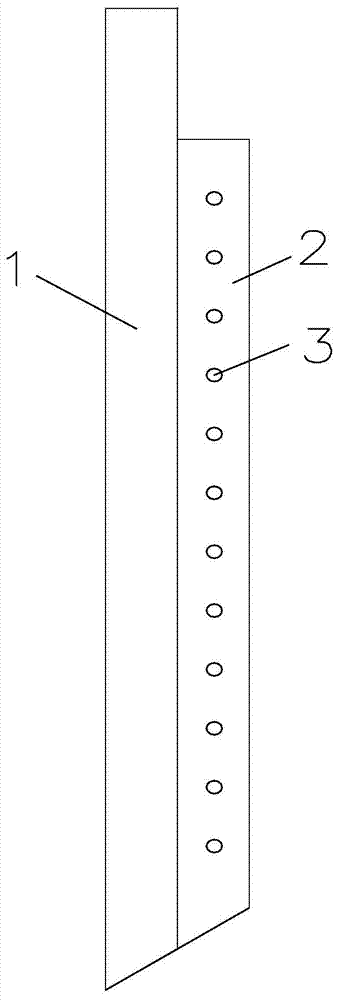

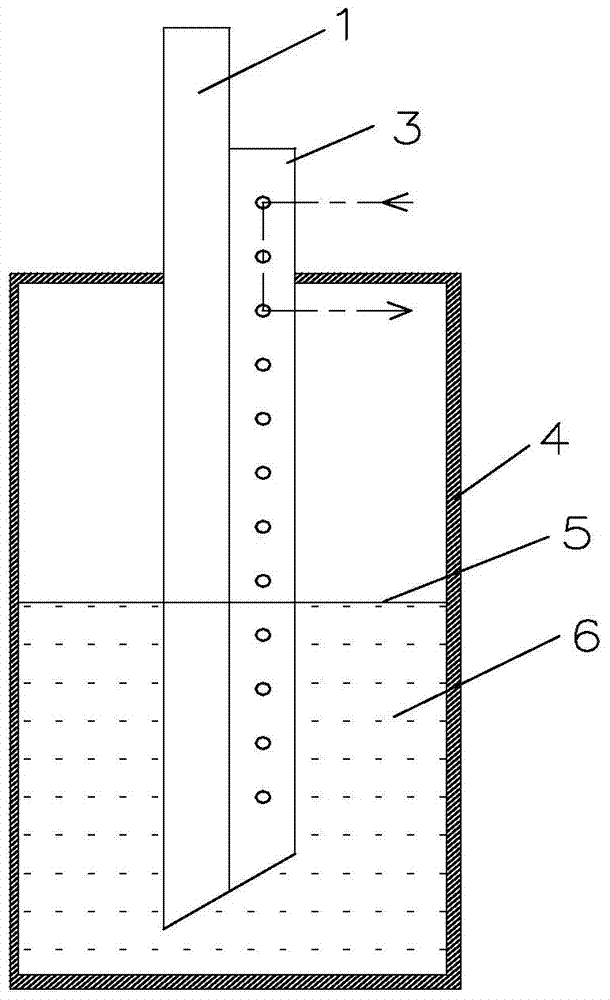

[0027] Embodiment 1: as Figure 1-4 , a composite anti-blocking suction pipe, comprising a main pipe 1 and a secondary pipe 2 glued together side by side; a plurality of ventilation holes 3 are arranged on the pipe wall of the secondary pipe along the axis of the secondary pipe.

[0028] The length of the main pipe is greater than that of the auxiliary pipe; and the top of the main pipe is higher than the top of the auxiliary pipe.

[0029] Both the main pipe and the secondary pipe have a diagonal cut at the bottom end.

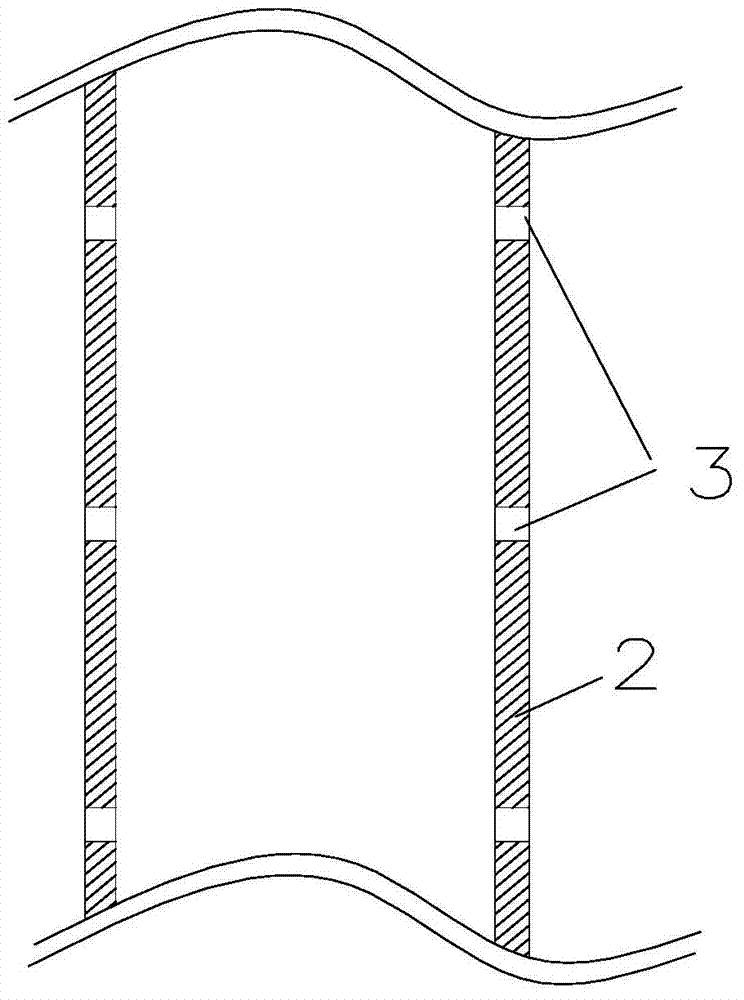

[0030] A plurality of ventilation holes are arranged at equal intervals and spread all over the pipe wall of the auxiliary pipe along the axial direction of the auxiliary pipe.

[0031] The vent holes are in multiple groups.

[0032] There are two groups of vent holes, which are arranged symmetrically with respect to the axis of the secondary pipe. When bonding the main pipe and the auxiliary pipe like this, it can be guaranteed that the two groups of hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com