Premixed adjustable gas burner and method

A gas burner, premixed technology, applied in the field of kiln combustion, can solve the problems of natural gas waste, poor natural gas mixing, unfavorable kiln atmosphere stability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

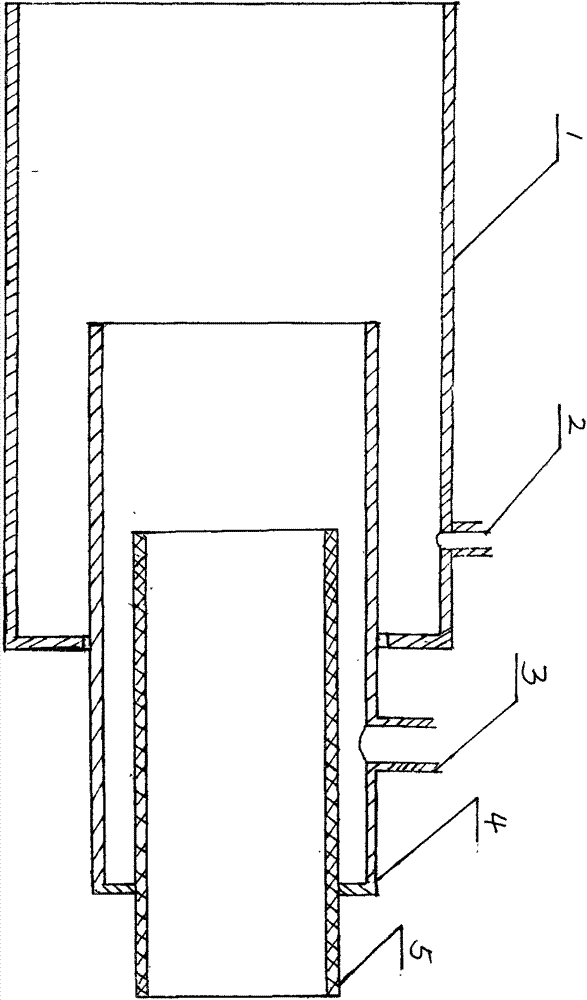

[0009] Such as figure 1 The specific embodiment of the premixed pressure regulating secondary gas burner and method of the present invention is shown, which is characterized in that a gas pipe 5 is provided, and the gas pipe 5 is fixedly linked with the mixing pipe 4, and the mixing pipe 4 is set outside the gas pipe 5 The mixing tube 4 is provided with a secondary tuyere 3, a certain gap is left between the mixing tube 4 and the air tube 1, the air tube 1 is set outside the mixing tube 4, and the air inlet tube 1 is provided with a main tuyere 2.

[0010] In the present invention, the fuel gas mixture flame is effectively utilized by adjusting the mixing tube, the natural gas and air are fully mixed in the mixing tube, and the air intake volume of the main tuyere and the secondary tuyere is adjusted to properly mix the gas to reduce the consumption of gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com