Mechanical adjusting premixing type secondary fuel gas nozzle and method

A gas burner and mechanical adjustment technology, which is applied in the field of kiln combustion, can solve the problems of excess supporting gas, insufficient combustion of gas, and large heat loss of the kiln, and achieve the effect of reducing dosage and improving sintering quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

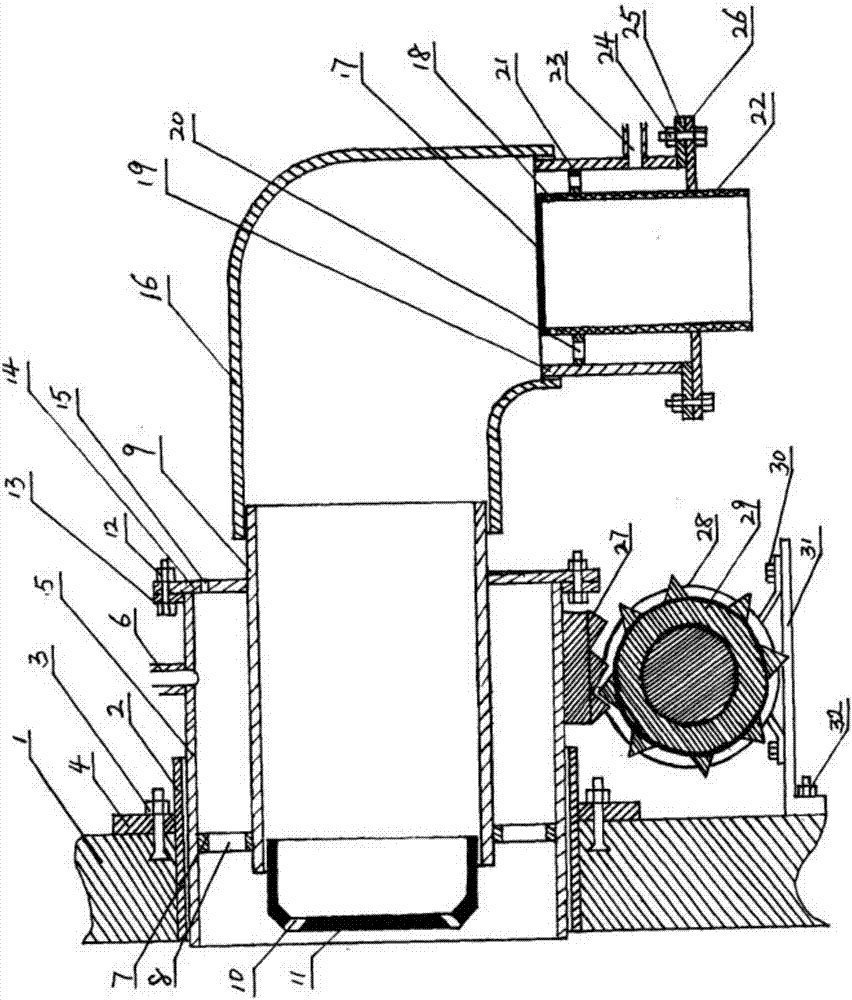

[0010] like figure 1 The specific embodiment of the mechanically adjusted premixed secondary gas burner and method of the present invention is shown, which is characterized in that a gas pipe 22 is provided, and a plug 17 is arranged at the front end of the gas pipe 22, and the front end of the gas pipe 22 is close to the plug One end of 17 is provided with a plurality of gas outlets 18, and the gas pipe 22 is provided with a second fixing bracket 21 near the gas outlet 18, and a plurality of gas injection holes 20 are uniformly arranged on the second fixing bracket 21, and the tail end of the gas pipe 22 is provided with There is a link disc-b26, and the link disc-b26 is tightly connected to the flange-b25 fixed at the end of the air intake pipe 19 through the flange bolt-b24, and the end of the air intake pipe 19 close to the flange-b25 is provided with a secondary air port 23. The front end of the air inlet pipe 19 is tightly connected to the tail end of the connecting elbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com