A device and method for monitoring leakage of hydraulic structures

A structural and hydraulic technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the personal safety threat of the operator, the difficulty of the peripheral current heating system, and the obstruction Technology application and promotion, etc., to achieve the effect of improving monitoring accuracy, improving transportation and layout capabilities, and improving engineering practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

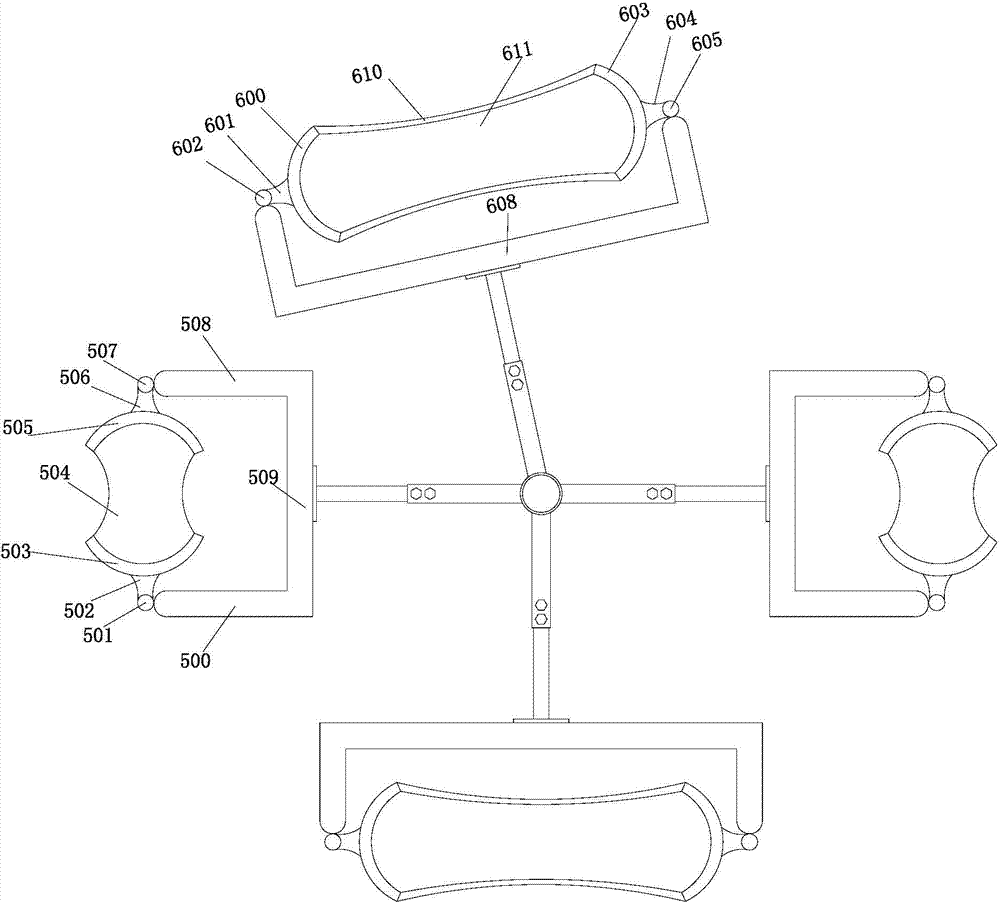

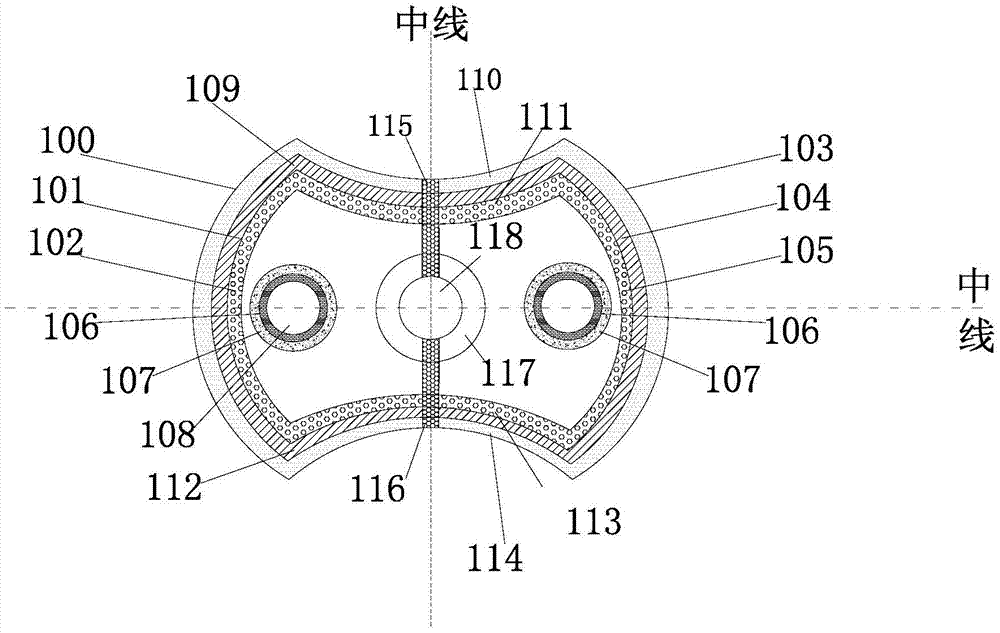

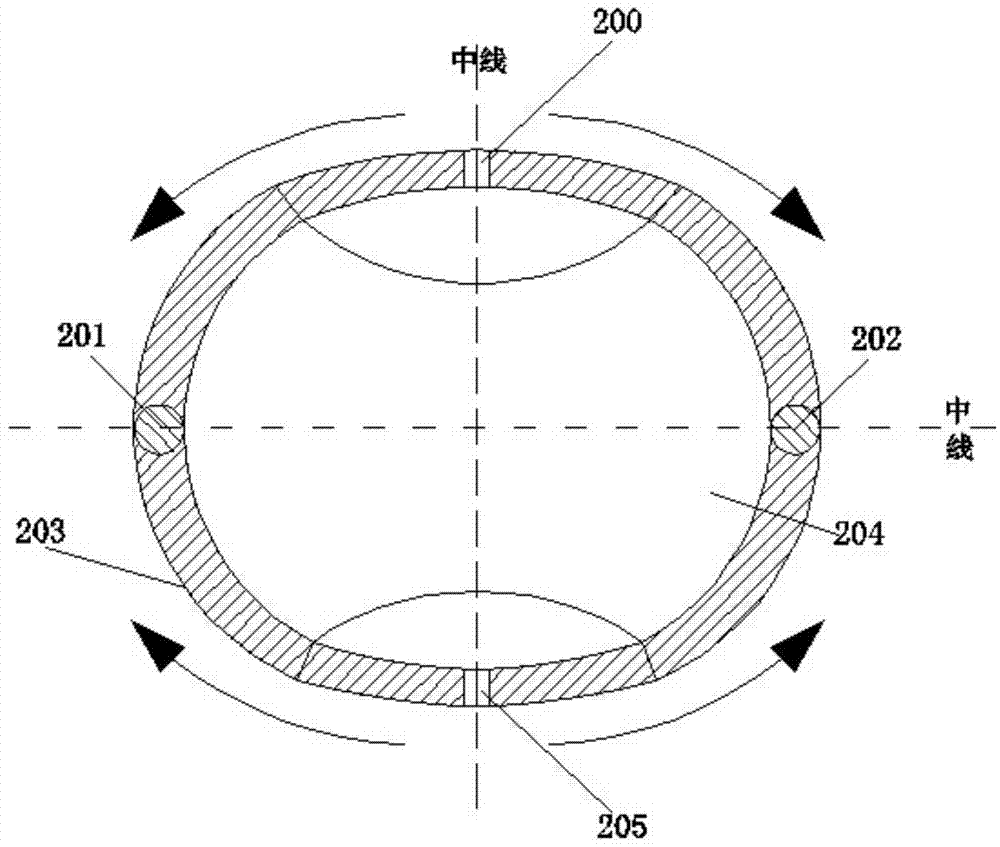

[0033] Such as Figure 1 to Figure 6 As shown, a device for monitoring leakage of a hydraulic structure of the present invention includes several seepage monitoring modules distributed in the hydraulic structure. Two seepage monitoring units and a telescopic support connected to the first seepage monitoring unit and the second seepage monitoring unit.

[0034] The first seepage monitoring unit includes the first fiber-carrying groove 611 for fixing the monitoring fiber unit, the first fiber-carrying groove 611 is provided with a fiber-carrying sheath 610, and the two ends of the first fiber-carrying groove 611 are respectively provided with left fiber-carrying channels end 600 and the right fiber end 603, the left fiber end 600 is connected to the left ball 602 through the left handle 601, the right fiber end 603 is connected to the right ball 605 through the right ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com