Method for measuring shaft torque, rotary speed and power parameters of power device based on double cameras

A power device, dual camera technology, applied in the field of power parameter measurement, speed, power device shaft torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

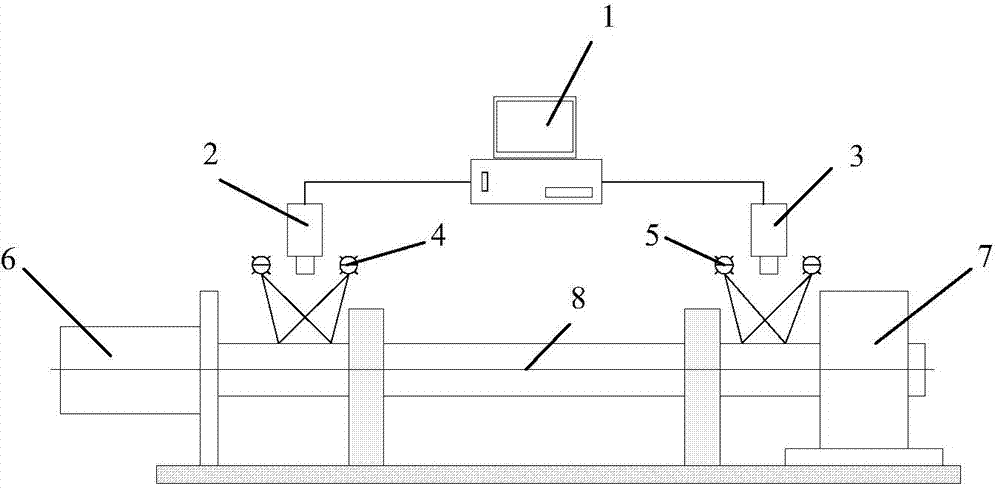

[0029] combine figure 1 , illustrate the implementation process of the present invention:

[0030] Based on the dual camera shaft torque, speed and power parameter measurement method of the power unit, the power unit 6, the transmission shaft 8, and the load 7 are connected in sequence;

[0031] On the outer peripheral surface of the transmission shaft, two circles of random identification patterns are arranged in parallel and at intervals, which are respectively the first random identification pattern and the second random identification pattern; the corresponding first camera 2 is arranged at the first random identification pattern, and the second random identification pattern The corresponding second camera 3 is arranged at the pattern; the first camera and the second camera are synchronously controlled by the synchronous controller; the first camera, the second camera, and the synchronous controller are connected to the host computer 1, and the first image storage unit is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com