Lead storage battery

A lead-acid battery and lead-sleeve technology, applied in lead-acid batteries, battery pack parts, battery caps/end caps, etc., can solve the problems of sacrificing battery capacity performance and service life, unable to ensure liquid leakage, and easy to be damaged, etc. To achieve the effect of excellent vibration resistance and capacity characteristics, good leakage resistance, and avoiding acid climbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

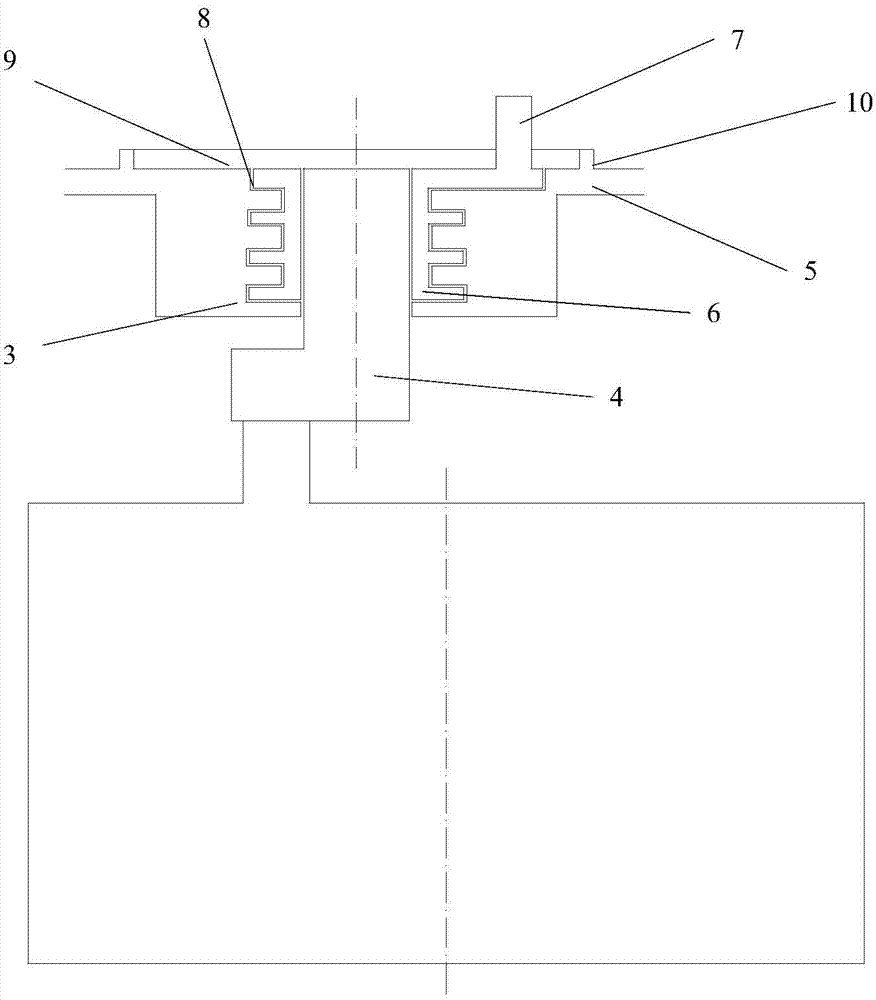

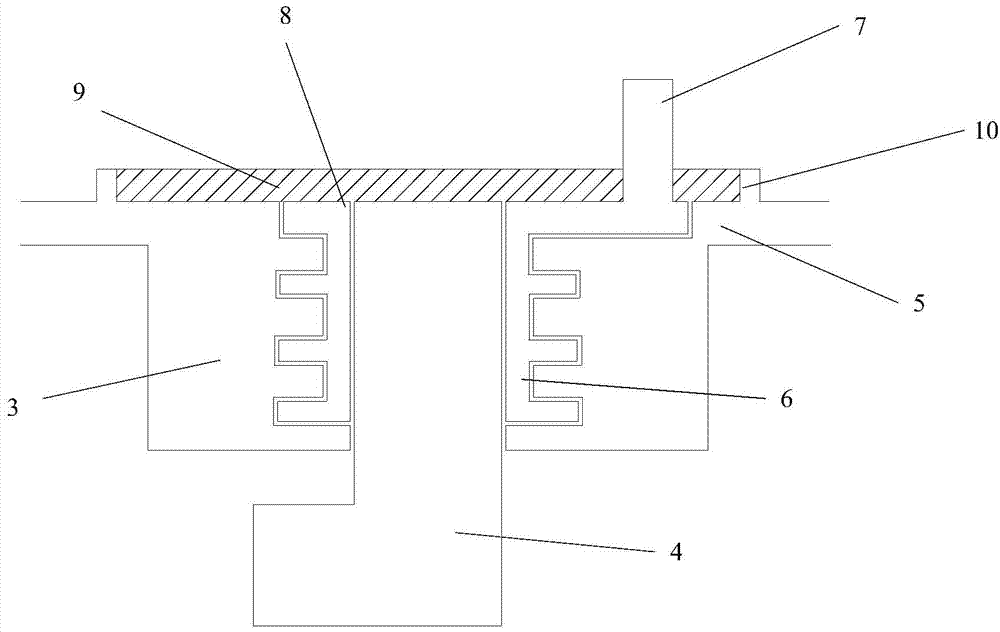

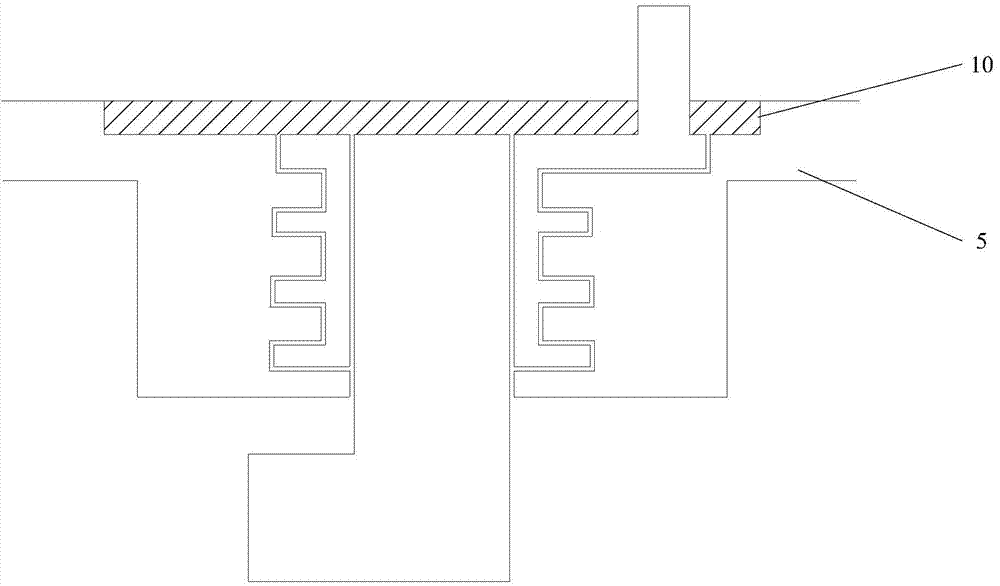

[0063] The lead storage battery of this embodiment is as figure 2 with image 3 As shown, the terminal post 4 is inserted into the tubular lead sleeve 6 pre-embedded in the receiving portion 3 on the lower surface of the middle cover 5 in a penetrating manner, and the above-mentioned terminal post 4 and the above-mentioned tubular lead sleeve 6 are welded Integrate, at least a part of the upper surface of the above-mentioned middle cover 5, the upper end surface of the above-mentioned terminal pole 4 and the upper end surface 6 of the above-mentioned lead sleeve are aligned to form a plane, and the above-mentioned terminal pole 5 and the electrode terminal 7 are welded into one body, at least A resin layer 9 is formed on at least a part of each of the upper surface of the above-mentioned middle cover and the upper end surface of the above-mentioned lead sleeve so as to cover the gap 8 existing at the interface between the above-mentioned lead sleeve 6 and the above-mentioned ...

Embodiment approach 2

[0071] The lead acid battery of Embodiment 2 differs from the lead acid battery of Embodiment 1 only in that the above-mentioned resin layer is not a hot-melt adhesive layer but a photocurable resin adhesive layer. The photocurable resin binder is not particularly limited, and may be, for example, an acrylic monomer oligomer binder or a cationic curing binder mainly used in combination with an epoxy resin.

[0072] According to the final technical effect to be achieved, other constituent elements can be appropriately selected from the foregoing detailed description.

Embodiment approach 3

[0074] The lead acid battery of Embodiment 3 differs from the lead acid battery of Embodiment 1 only in that the above-mentioned resin layer is not a photocurable resin adhesive layer, but is made of a material other than a photocurable resin adhesive or a hot-melt adhesive. An adhesive resin layer such as an epoxy resin layer is formed.

[0075] According to the final technical effect to be achieved, other constituent elements can be appropriately selected from the foregoing detailed description.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com