The electromagnetic valve

A solenoid valve and valve hole technology, applied in the field of solenoid valves, can solve the problem of inability to generate electromagnetic force, and achieve the effect of cheap implementation and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

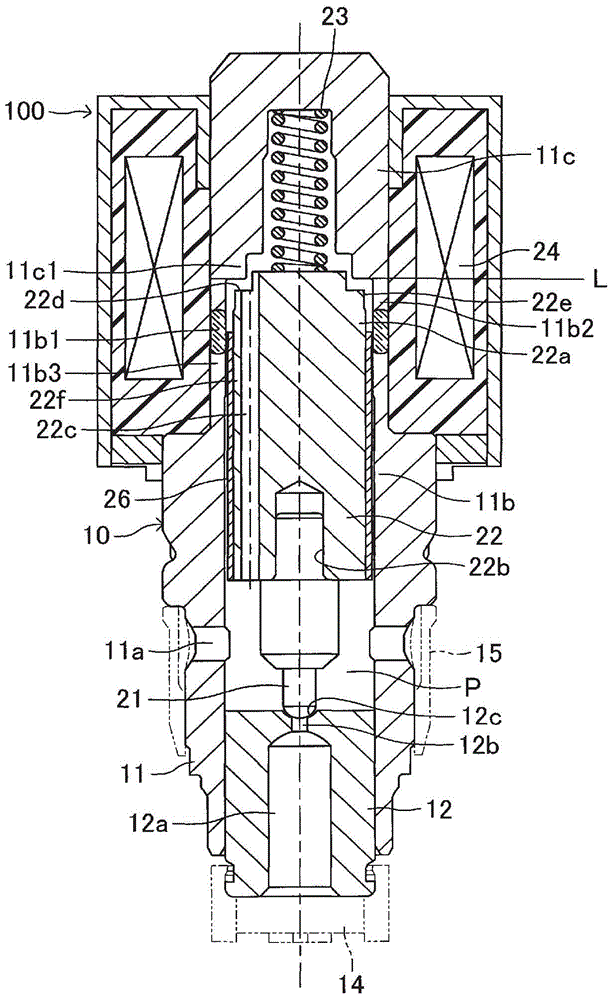

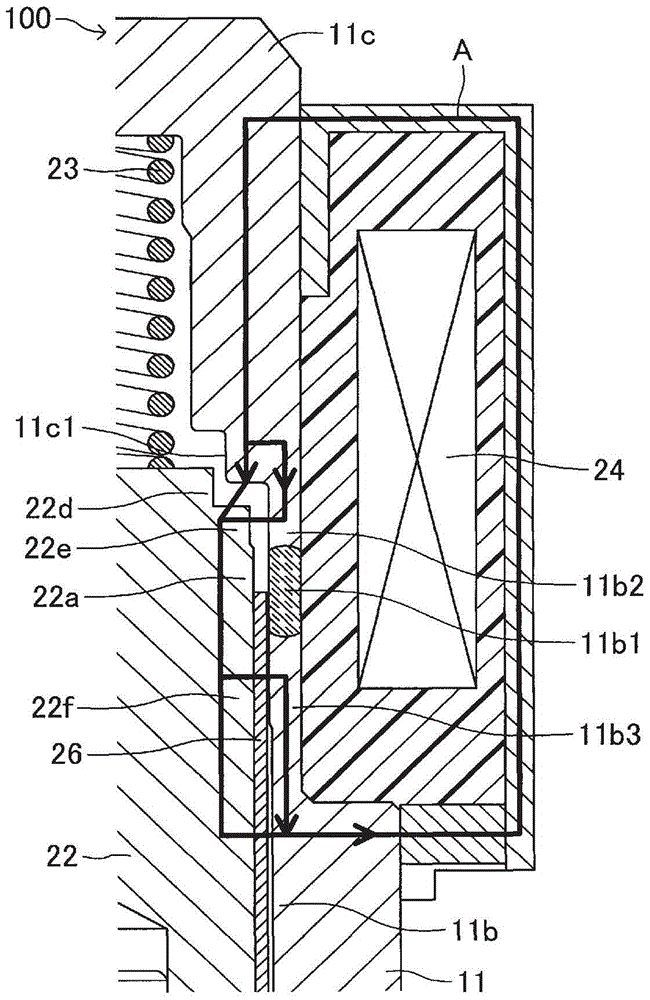

[0019] Embodiments of the present invention will be described below based on the drawings. figure 1 An embodiment of a solenoid valve according to the present invention is shown in . The solenoid valve 100 is, for example, a hydraulic control device incorporated in a hydraulic brake system for a vehicle, and is a normally closed solenoid valve used for hydraulic control of brake fluid. In addition, in this solenoid valve 100 , a valve element 21 , a movable iron core 22 , a spring 23 , a coil 24 , and the like are assembled in the case 10 .

[0020] The housing 10 includes a cylindrical housing main body 11 and a cylindrical seat member 12 assembled to the inner periphery of the lower end portion of the housing main body 11 so as to be positionally adjustable in the vertical direction. The housing main body 11 houses a valve element 21, a movable iron core 22, a spring 23, and the like inside, and is provided with a plurality of fluid outlets 11a on the lower side in the drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com