A metal 3d printer

A 3D printer, metal technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

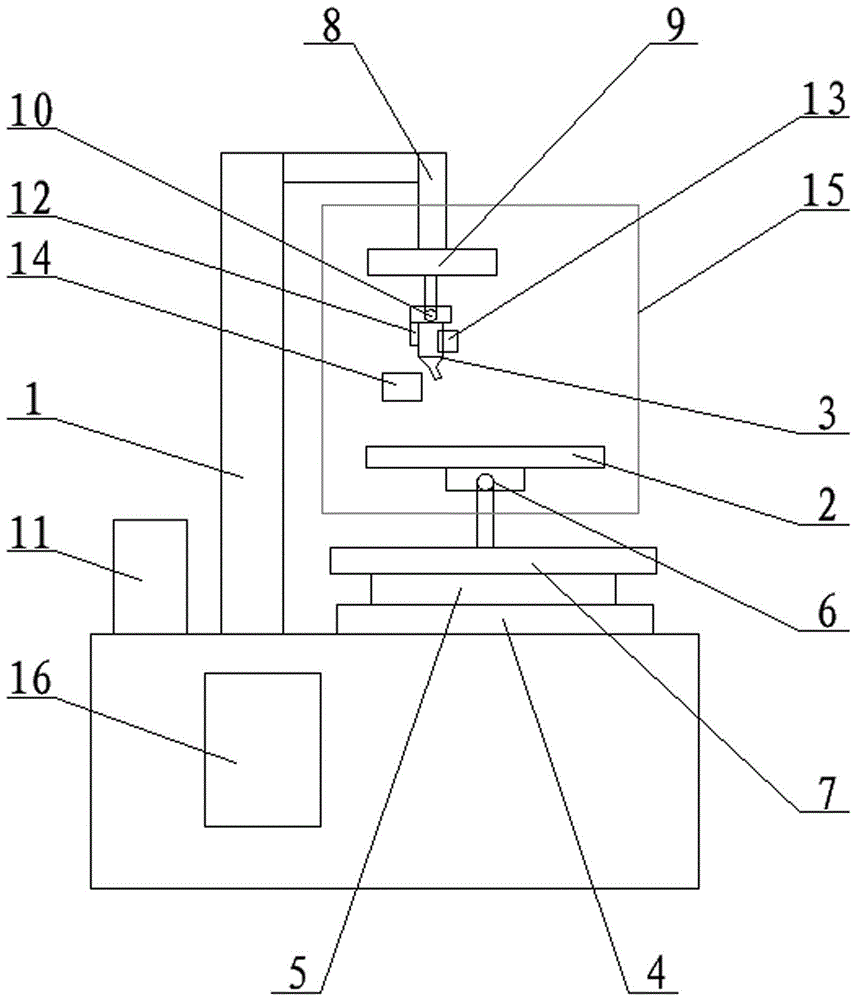

[0025] The present invention will be further described below in conjunction with accompanying drawing.

[0026] figure 1 As shown, a metal 3D printer includes a frame 1, a workbench 2, a print head 3, a workbench transverse movement mechanism 4, a workbench longitudinal movement mechanism 5, a workbench vertical rotation mechanism 6, a workbench horizontal rotation mechanism 7, a printing Head vertical linear motion mechanism 8, print head horizontal rotation mechanism 9, print head vertical rotation mechanism 10, metal wire storage mechanism 11, deceleration feeding mechanism 12, metal heating mechanism 13, cooling mechanism 14, gas protection mechanism 15 and electric control Box 16. The frame 1 is supported with a workbench transverse movement mechanism 4 and a workbench longitudinal movement mechanism 5 which are superimposed on each other. The workbench horizontal rotation mechanism 7 is installed on the workbench transverse movement mechanism 4 or the workbench longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com