Diffusion connection mold and diffusion connection method

A technology of diffusion connection and mold, which is applied in the field of precision sheet metal processing, can solve the problems that affect the quality and pass rate of parts, the difficulty of mold processing, and the high flatness requirements, so as to improve production efficiency, shorten production cycle and improve pass rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

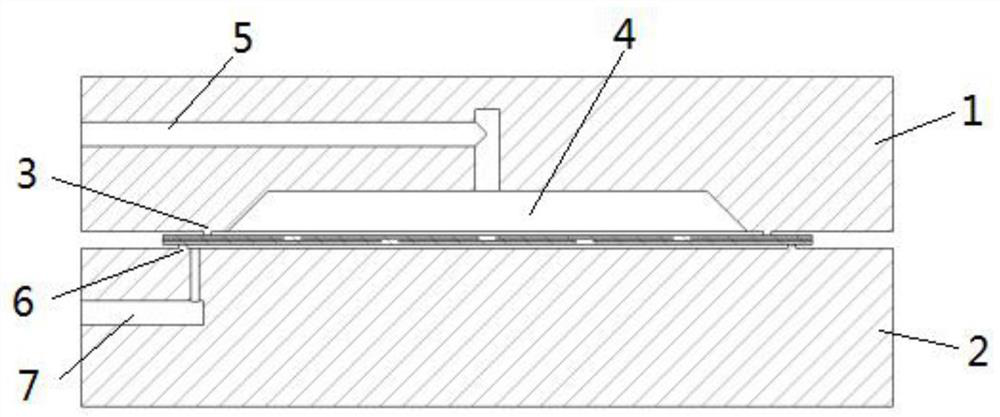

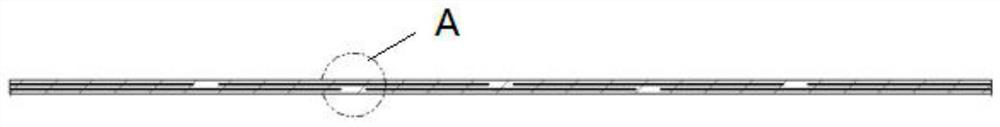

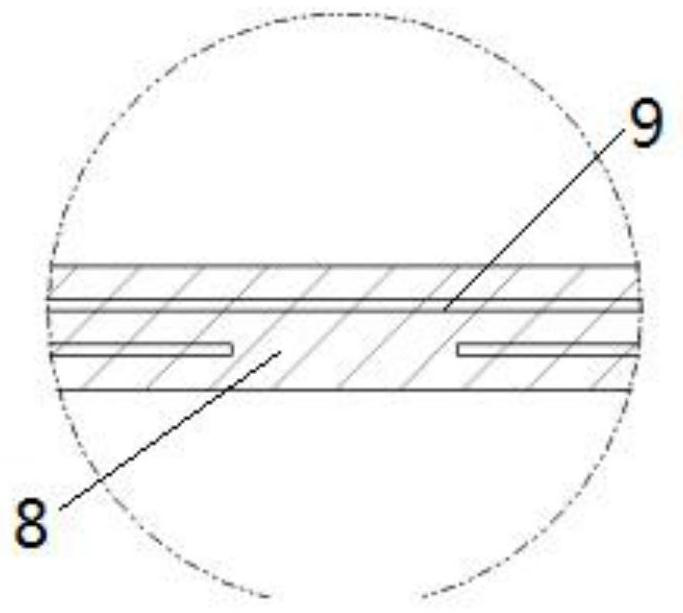

[0041] Such as figure 1 As shown, this embodiment provides a diffusion bonding mold. The diffusion connection mold includes an upper mold 1 and a lower mold 2 matched with the upper mold. The upper mold 1 is provided with a first sealing stem 3, an air cavity 4 and an air passage 5 for filling the air cavity with high-pressure flexible gas; the lower mold 2 It is a flat plate structure, and the lower mold 2 is provided with a second sealing stem 6 and a vacuum air channel 7 .

[0042] The upper mold has a sealing stem, an air cavity and an air passage; the lower mold is a flat plate structure with a sealing stem and a vacuum air passage. The air passage of the upper mold is used to fill the air cavity with high-pressure flexible gas, and the vacuum air passage of the lower mold is used for vacuuming the gap between the lower mold and the multilayer board. Compared with the prior art, the lower mold of the mold provided by the present invention adopts a flat plate structure, ...

Embodiment 2

[0048] This embodiment provides a method of diffusion connection, using, for example, the diffusion connection mold of embodiment 1, the method of diffusion connection includes the following steps:

[0049] S1. Diffusion connection mold making;

[0050]S2. Design and manufacture of large-area diffusion connection blanks for multi-layer boards;

[0051] S3, performing surface treatment on the large-area diffusion-connected blank of the multi-layer board;

[0052] S4. Production of release agent patterns for large-area diffusion-connected blanks of multi-layer boards;

[0053] S5. Large-area diffusion connection blank assembly of multi-layer boards, peripheral fusion welding and vacuum tube welding to obtain multi-layer board seals;

[0054] S6. Diffusion connection of multi-layer board seals, including the following steps:

[0055] S61. Put the multi-layer plate seal in S5 between the upper mold and the lower mold, connect the air passage of the upper mold with the inflation...

Embodiment 3

[0071] This embodiment provides a large-area diffusion bonding method for a 5A90 aluminum-lithium alloy three-layer board part (length 1200 mm, width 400 mm). This embodiment uses the mold of Example 1, and the method includes the following steps:

[0072] S1. Design and manufacture the diffusion connection mold according to the size of the three-dimensional model of the 5A90 aluminum-lithium alloy three-layer board part. The size of the large-area diffusion connection area is enlarged by 3.5‰ according to the size of the part;

[0073] S2. Carry out the blank design of the 5A90 aluminum-lithium alloy three-layer board. The blanking size of the three boards is 1220mm×420mm, and the blanking method adopts water cutting;

[0074] S3. Use a mixture of hydrofluoric acid and nitric acid to pickle the surface of the three 5A90 aluminum-lithium alloy plates to remove the surface scale; and draw the division of the diffusion connection area and the non-diffusion connection area of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com