Punching and cutting machine with base tape and protective film and cutting method

An all-in-one, protective film technology, used in metal processing, sending objects, thin material processing, etc., can solve the problems of low labor efficiency, many steps, and uneven protective film strips, and achieve high production efficiency and good product quality. , The operation steps are simple and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. However, it should be noted that the implementation of the present invention is not limited to the following embodiments.

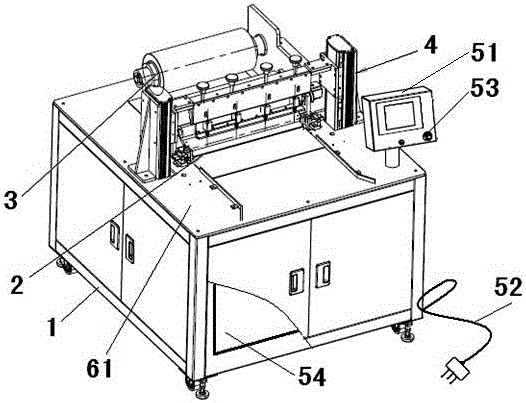

[0059] see figure 1 . An integrated punching and cutting machine with base tape and protective film, including machine table 1, tape feeding system 2, protective film feeding and processing system 3, punching system 4, control box 51, control system 54 and power supply 52 . The machine 1 adopts a box-shaped structure, and corresponding production tools, spare parts and maintenance tools can be placed in the box-shaped structure.

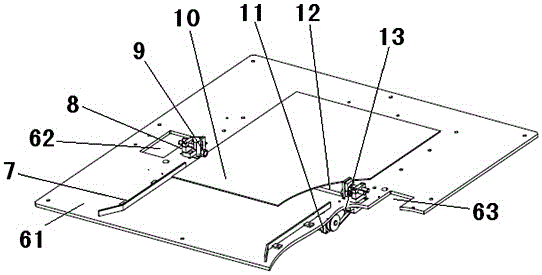

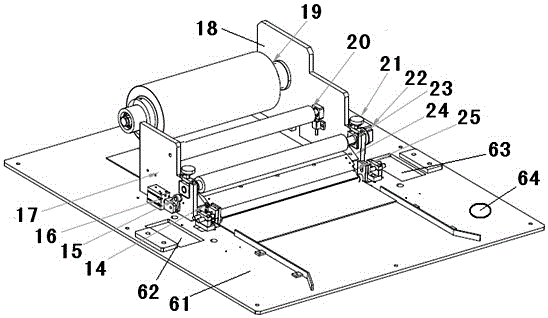

[0060] A table top 61 is arranged on the top of the machine table 1 . The table top 61 can be made of metal plate to enhance its firmness and load-bearing capacity. A first connection hole 62 and a second connection hole 63 are provided on both sides of the middle of the table top 61 in the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com