Composite air bubble film

A technology of air bubble film and air bubble layer, which is applied in the field of composite packaging materials and composite air bubble film, can solve the problems of poor cushioning performance and strength, easy to wear workpiece surface, single function of air bubble paper, etc., and achieves wide application, increased practical performance, The effect of strong buffer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

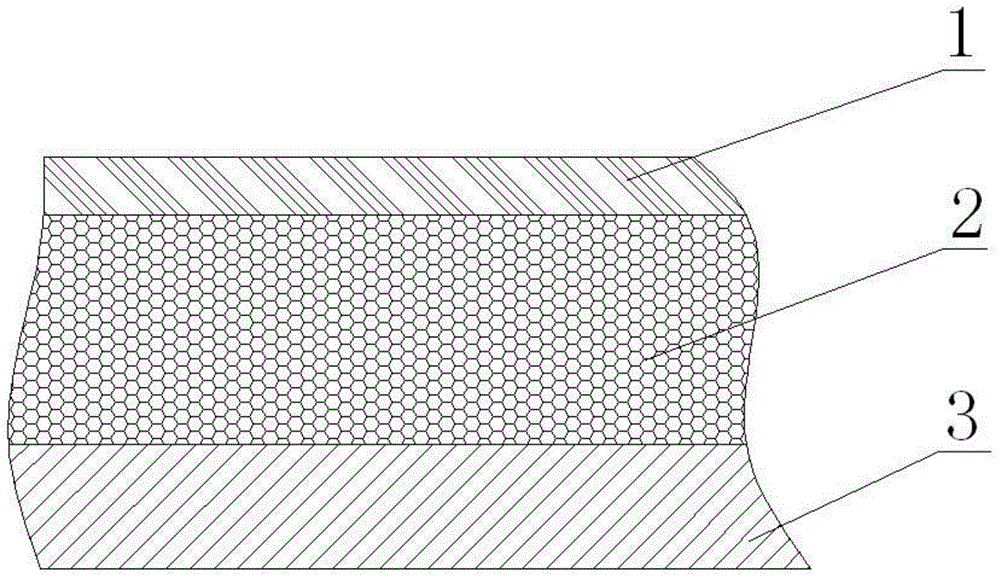

[0017] The braided layer 1 is a plastic braided belt with a thickness of 0.3 mm, which has the functions of high strength and tear resistance. The bubble layer is bubble paper, the thickness of the bubble layer is 2.2 mm, and it has cushioning, abrasion resistance, rainproof, shock absorption, impact resistance and thermal sealing properties. The PE foam layer is PE foam paper, and the thickness of the PE foam layer is 1 mm, which can protect the surface of the packaged workpiece.

Embodiment 2

[0019] The braided layer 1 is a plastic braided belt with a thickness of 0.5mm, which has the functions of high strength and tear resistance. The bubble layer is bubble paper, the thickness of the bubble layer is 3 mm, and it has cushioning, wear-resistant, rainproof, shock-absorbing, impact-resistant and heat-sealing properties. The PE foam layer is PE foam paper, and the thickness of the PE foam layer is 0.5mm, which can protect the surface of the packaged workpiece.

Embodiment 3

[0021] The braided layer 1 is a plastic braided belt with a thickness of 1mm, which has the functions of high strength and tear resistance. The bubble layer is bubble paper, the thickness of the bubble layer is 3.5 mm, and it has cushioning, abrasion resistance, rainproof, shock absorption, impact resistance and thermal sealing properties. The PE foam layer is PE foam paper, and the thickness of the PE foam layer is 2 mm, which can protect the surface of the packaged workpiece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com