Backrest frame mechanism

A backrest frame and frame technology, applied to railway car body parts, seats, transportation and packaging, etc., can solve the problems of backrest cushion damage, cover damage, stress concentration, etc., and achieve convenient connection and disassembly, comfortable ride feeling, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

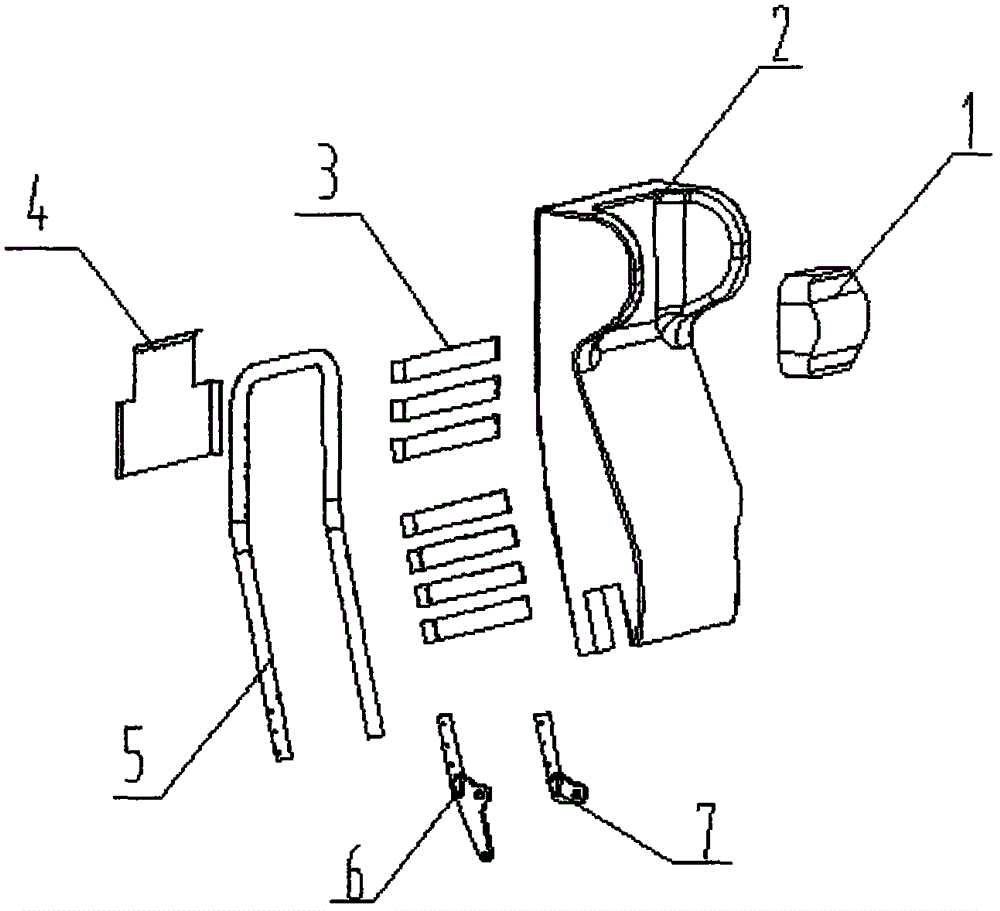

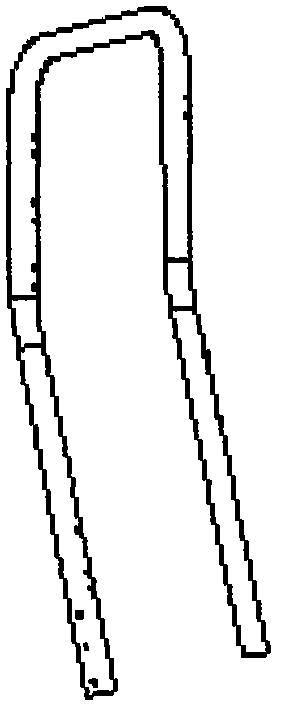

[0025] Such as figure 1 As shown, a backrest frame mechanism includes a headrest, a backrest cushion, a front cover, a rear cover, a U-shaped frame, a first longitudinal beam, and a second longitudinal beam, and the front and rear sides of the U-shaped frame are fixedly connected respectively. The front cover, the rear cover, the front side of the front cover is also fixed with a back cushion, the back cushion is put on the U-shaped frame, the headrest is arranged on the top of the back cushion, and the first The longitudinal beam and the second longitudinal beam are fixedly arranged on the bottom of the U-shaped frame.

Embodiment 2

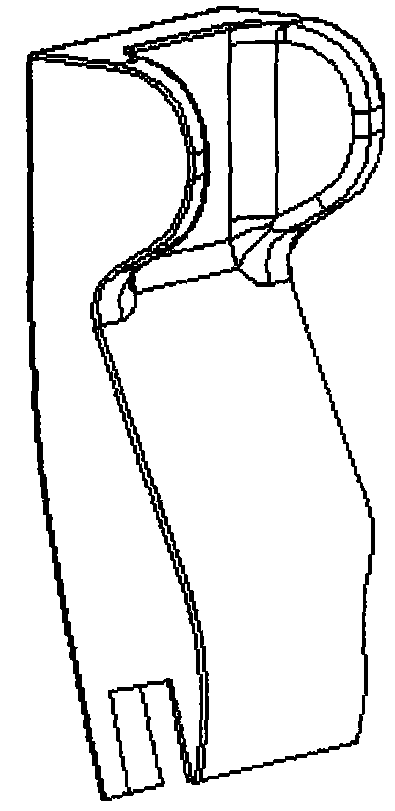

[0027] Such as figure 1 As shown, a backrest frame mechanism includes a headrest, a backrest cushion, a front cover, a rear cover, a U-shaped frame, a first longitudinal beam, and a second longitudinal beam, and the front and rear sides of the U-shaped frame are fixedly connected respectively. The front cover, the rear cover, the front side of the front cover is also fixed with a back cushion, the back cushion is put on the U-shaped frame, the headrest is arranged on the top of the back cushion, and the first The longitudinal beam and the second longitudinal beam are fixedly arranged at the bottom of the U-shaped frame, the cross-sectional area of the U-shaped frame is circular, the U-shaped frame has a smooth bend, the U-shaped frame, the front cover And the back cover is made of aluminum or aluminum alloy, and the front cover and the back cover are fixed to the U-shaped frame by riveting.

Embodiment 3

[0029] Such as Figure 2-4 As shown, in another specific embodiment of the present invention, the front cover is composed of several groups of horizontal bars, coat hooks and newspaper belts are also arranged on the rear cover, and the backrest cushion adopts memory Type sponge, the sponges on both sides of the top of the backrest cushion protrude in the shape of lugs, the headrest installed on the backrest cushion adopts an arc design, the headrest adopts memory foam, and the middle part of the headrest is A protrusion that fits a person's neck.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com