Automatic packing production line of square carpet and working method thereof

An automatic packaging and production line technology, applied in the field of high-end packaging equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

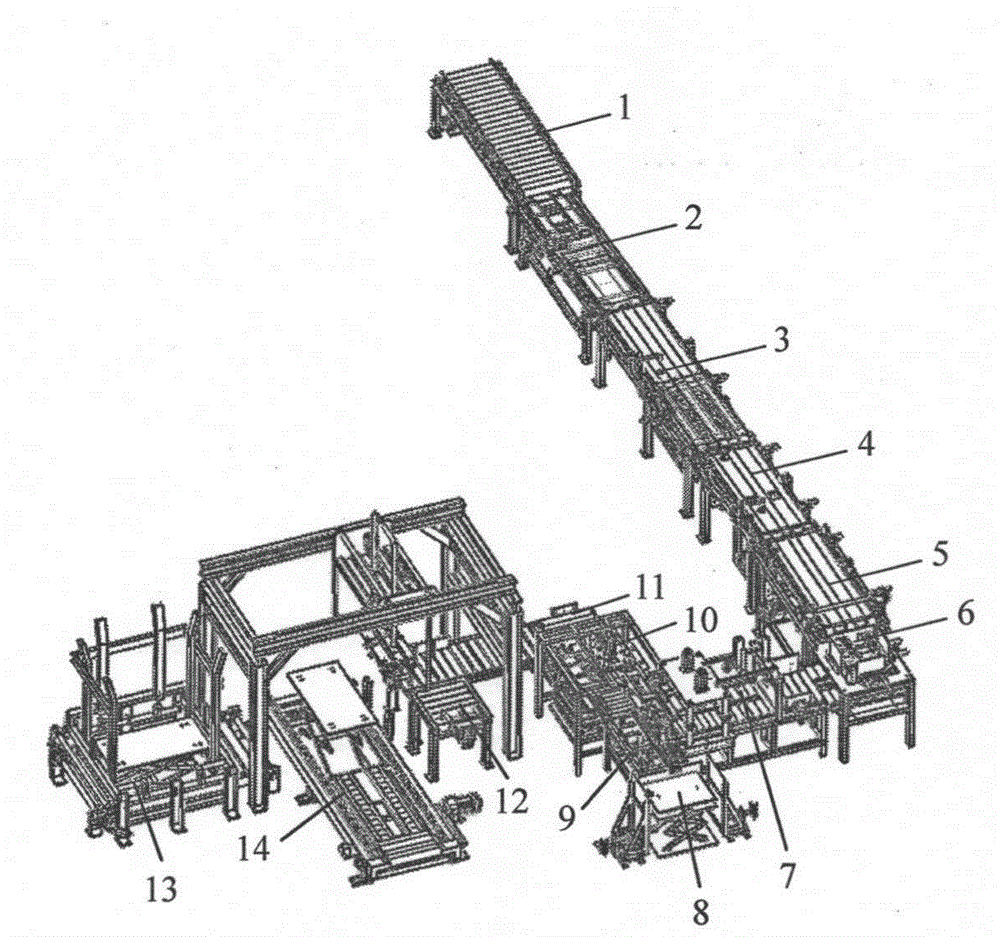

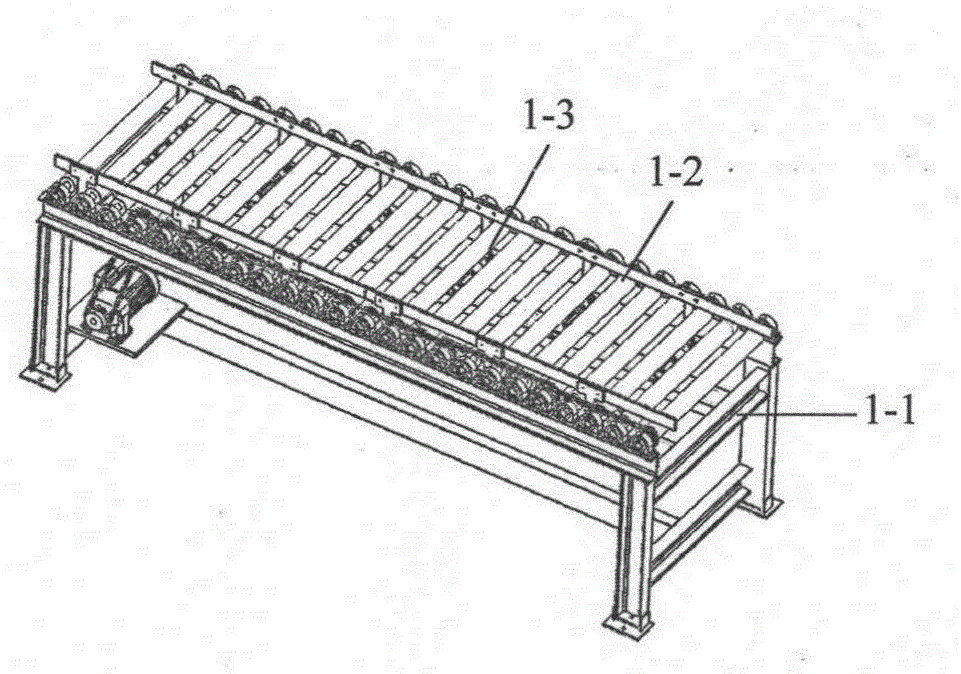

[0074] figure 1 The composition schematic diagram of the carpet tile automatic packaging production line provided by the present invention is composed of the following parts: cutting machine carpet output part 1, carpet conveying part 2, conveying turning part 3, carpet buffering part 4, stacking front part 5, carpet stacking Part 6, sorting and packing part 7, box taking part 8, box forming part 9, box part 10, rotation and reversing part 11, finished product conveying part 12, pallet supply part 13 and finished product stacking part 14, the mechanical structures of each part are in contact with each other Or connected, or placed at a certain distance.

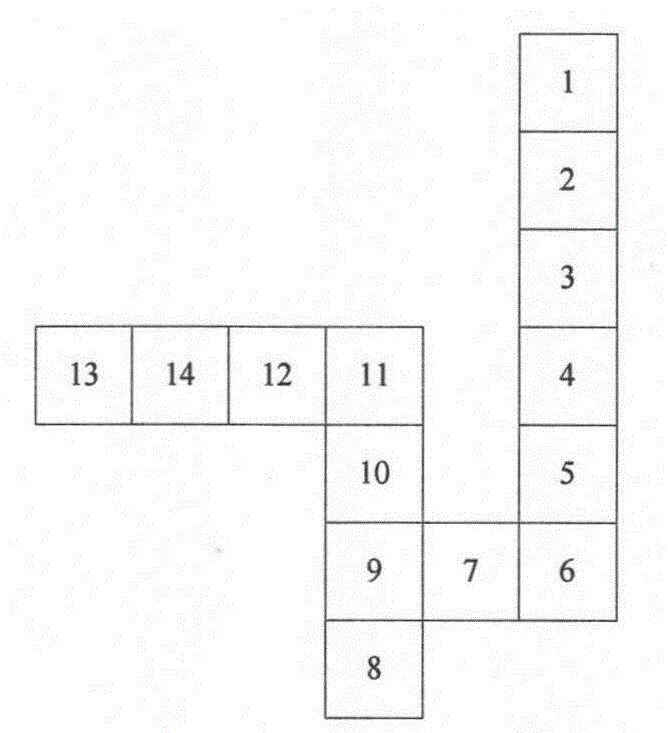

[0075] figure 2 It is a schematic diagram of the orientation of each component, and the arrangement of each part is as follows: in the carpet output direction of the carpet cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com