Large bag conveying and steering method and conveying and steering device

A steering device and bag-packing technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of bag retention, slow conveying, fatigue and wear of chains and idlers, and achieve the effect of improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

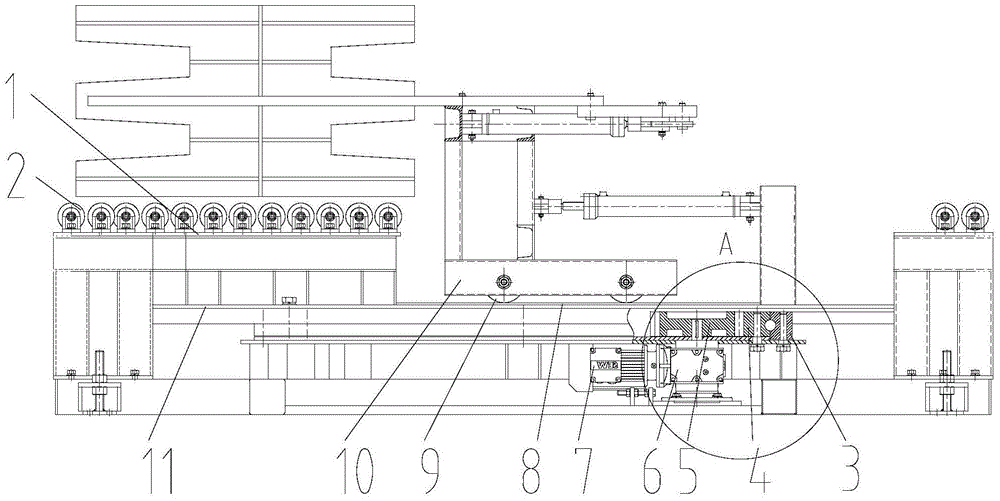

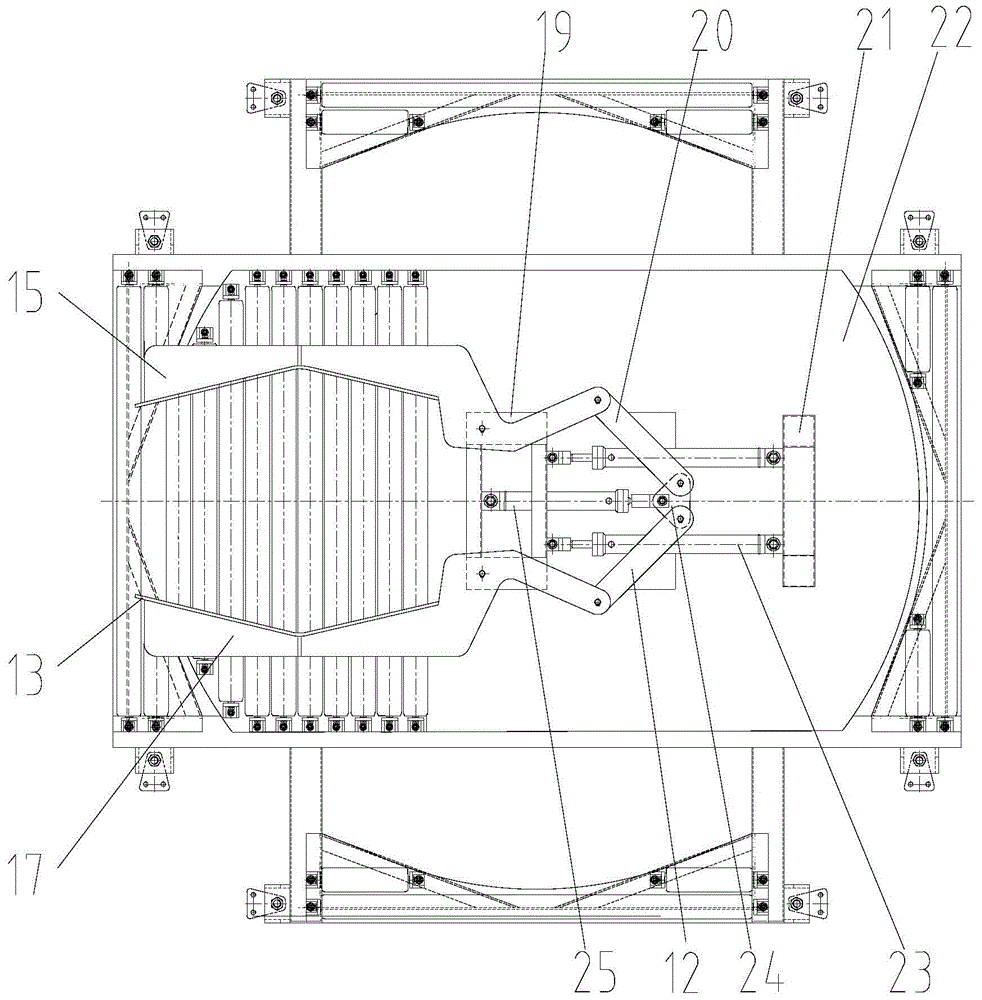

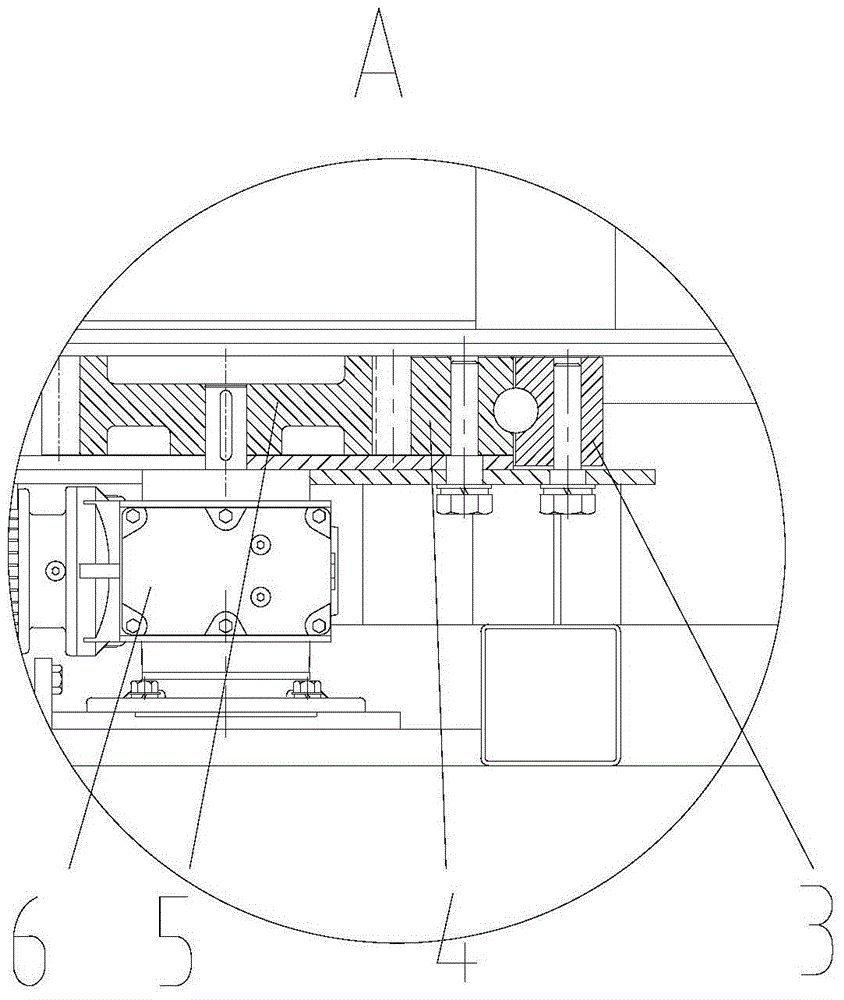

[0032] Such as figure 1 , 2 As shown in and 3, a large bag conveying steering device is characterized in that it has a clamping device, a dragging device and a rotary platform device, and the clamping device is located at the front end of the dragging device and is connected with the dragging device, The dragging device can move with the clamping device, the dragging device is located above the rotary platform device, and the rotary platform device can realize the rotation together with the dragging device and the clamping device.

[0033]Clamping device comprises clamping hydraulic cylinder 25, clamping plate 13, linkage plate 24, first connecting rod 20, second connecting rod 15, the 3rd connecting rod 12, the 4th connecting rod 17 and support 19, described clamping hydraulic cylinder The cylinder body part of 25 is fixedly installed on the bracket 19, and the extended end of the clamping hydraulic cylinder 25 is fixedly connected with the linkage plate 24, and the first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com