A connection structure between an air expansion shaft and a chuck body

A technology of connecting structure and inflatable shaft, applied in couplings, rigid shaft couplings, mechanical equipment, etc., can solve problems such as hidden dangers in production safety, large flange volume, cumbersome locking methods, etc., and achieve simple operation. Convenience and the effect of increasing the sliding friction stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

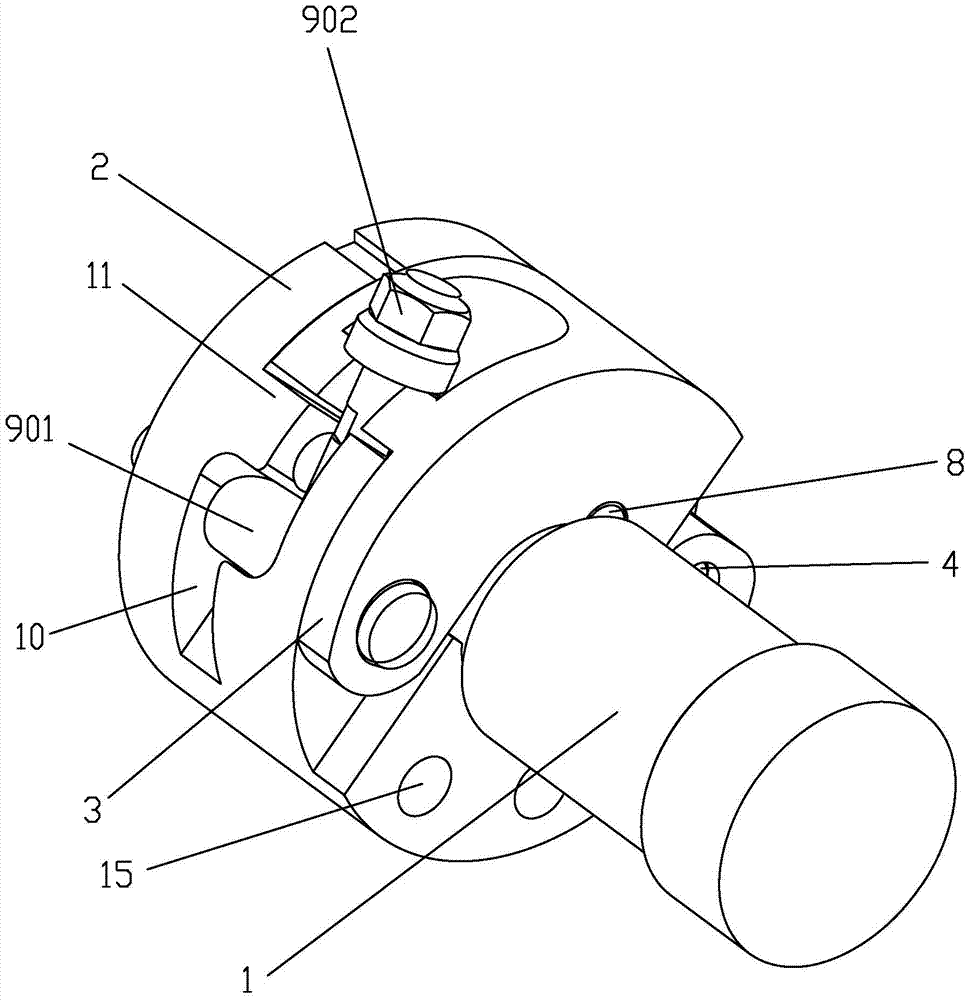

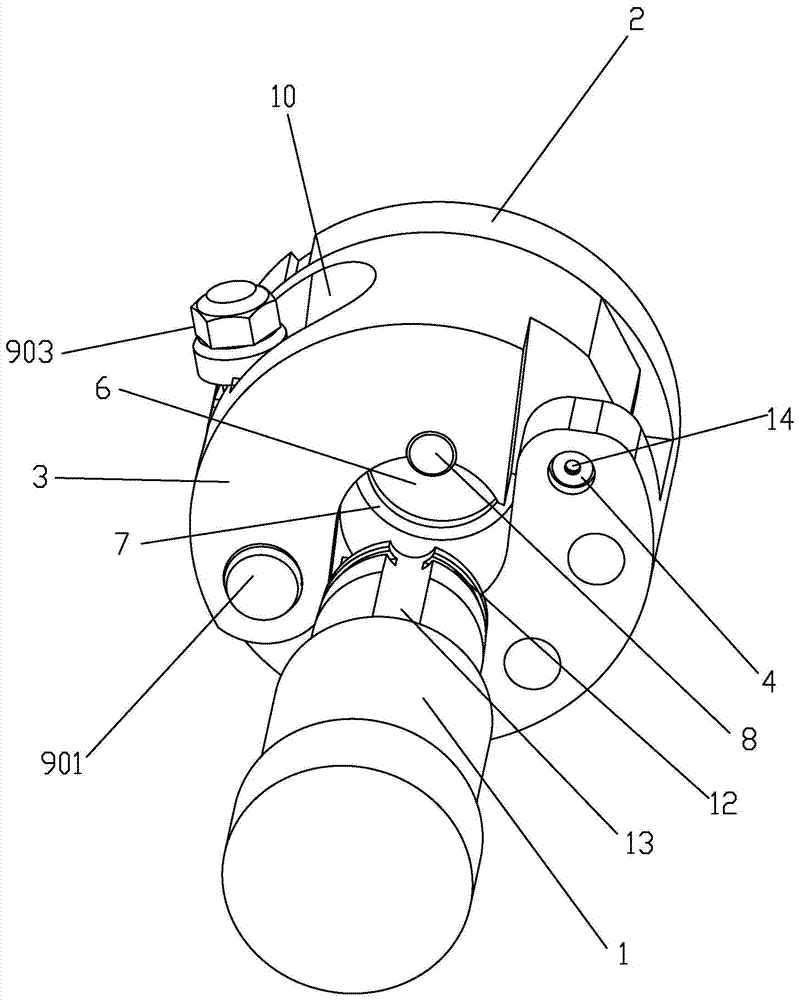

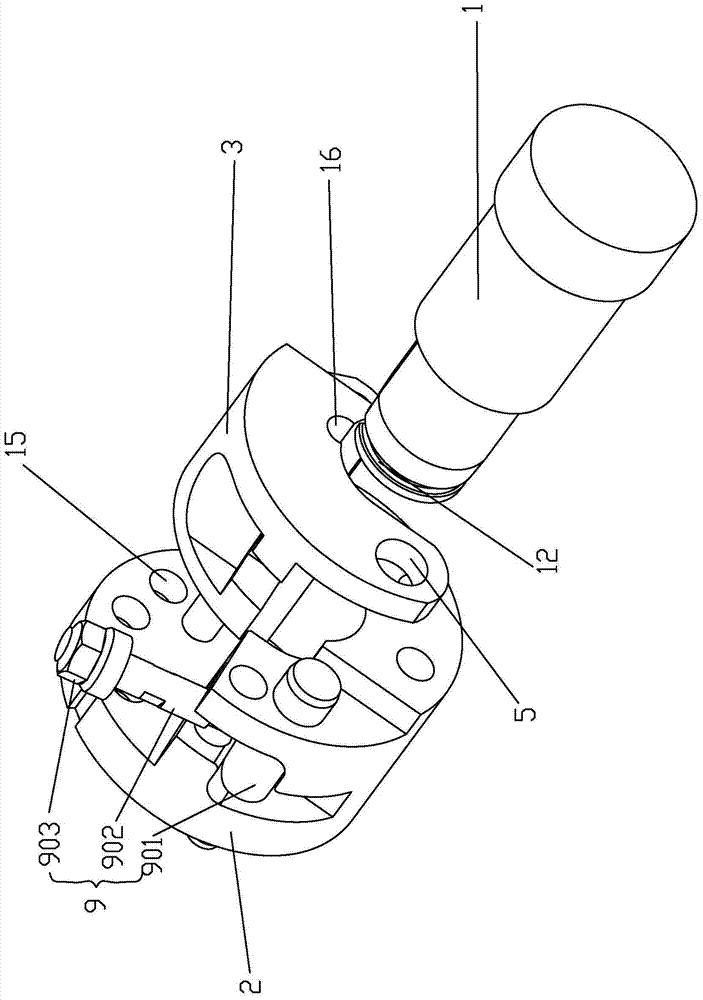

[0032] The technical features of the present invention will be described in further detail below in conjunction with the accompanying drawings so that those skilled in the art can understand.

[0033] A connection structure between an air shaft and a chuck body, including a chuck body 2, on which a gland 3 is hinged through a pin shaft 4, and the air shaft 1 is compressed by the rotation of the gland 3 On the chuck body 2, a movable locking pin 9 is also provided on the chuck body 2, and a locking hole 5 is arranged at the non-hinged end of the gland 3, and the dialable The moving locking pin 9 is inserted into the locking hole 5 to lock the gland 3.

[0034] The toggleable locking pin 9 includes a lower pin 901 inserted into the locking hole 5 and a toggle rod 902 for turning the lower pin 901. The toggle rod 902 is a screw rod. The chuck body 2 and the gland 3 are provided with a neutral slot 10 that limits the movement of the toggle lever 902, and the toggle lever 902 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com