A multi-branch heat pipe based on secondary sintering molding and its preparation method

A secondary sintering and multi-branch technology, applied in heat exchange equipment, lighting and heating equipment, heat exchanger shells, etc., can solve the problem of low space utilization, reduce the space required for heat dissipation, and reduce the preparation process Simple, Highly Flexible Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

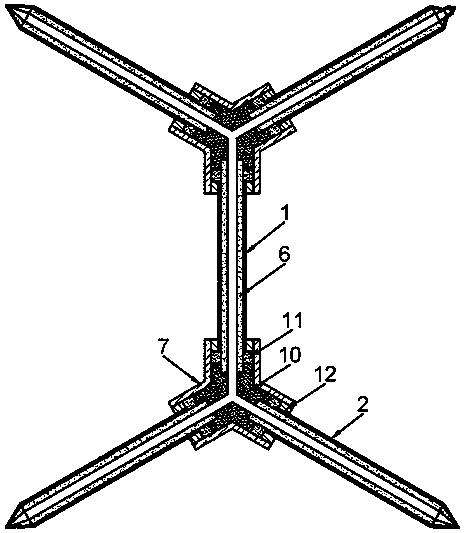

[0068] Preparation of the above-mentioned multi-branch pipe joints based on secondary sintering molding with 3 joints, double Y-shaped space multi-branch heat pipes:

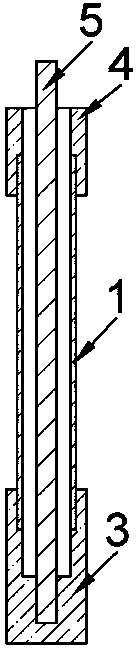

[0069] (1) Prepare the sintered mandrel for molding, including the first sintered mandrel 5 and the second sintered mandrel 9; the graphite set for fixing, including the first graphite set 3, the second graphite set 4 and the third graphite Set 8; clean and degrease the sealing cavity of the first shell 1, the second shell 2, the multi-branch pipe joint 7, the sealing ring plug 12 and the sintered mandrel;

[0070] The material of the sealing cavity of the first shell 1, the second shell 2, and the multi-branch pipe joint 7 is red copper;

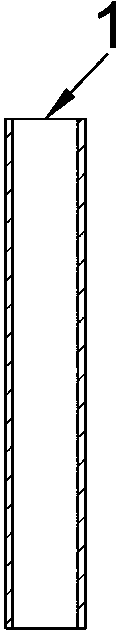

[0071] The sectional view of the first shell 1 is as figure 2 shown;

[0072] The first graphite sleeve is a graphite sleeve with three stepped holes that are concave and not through, and the diameter of the first stepped hole is equal to the outer diameter of the first sh...

Embodiment 2

[0080] Preparation of the above-mentioned multi-branch pipe joints based on secondary sintering molding with 3 joints, double Y-shaped space multi-branch heat pipes:

[0081] (1) Prepare the sintered mandrel for molding, including the first sintered mandrel 5 and the second sintered mandrel 9; the graphite set for fixing, including the first graphite set 3, the second graphite set 4 and the third graphite Set 8; clean and degrease the sealing cavity of the first shell 1, the second shell 2, the multi-branch pipe joint 7, the sealing ring plug 12 and the sintered mandrel;

[0082] The material of the sealing cavity of the first shell 1, the second shell 2, and the multi-branch pipe joint 7 is red copper;

[0083] The sectional view of the first shell 1 is as figure 2 shown;

[0084] The first graphite sleeve is a graphite sleeve with three stepped holes that are concave and not through, and the diameter of the first stepped hole is equal to the outer diameter of the first sh...

Embodiment 3

[0092] Preparation of the above-mentioned multi-branch pipe joints based on secondary sintering molding with 3 joints, double Y-shaped space multi-branch heat pipes:

[0093] (1) Prepare the sintered mandrel for molding, including the first sintered mandrel 5 and the second sintered mandrel 9; the graphite set for fixing, including the first graphite set 3, the second graphite set 4 and the third graphite Set 8; clean and degrease the sealing cavity of the first shell 1, the second shell 2, the multi-branch pipe joint 7, the sealing ring plug 12 and the sintered mandrel;

[0094] The material of the sealing cavity of the first shell 1, the second shell 2, and the multi-branch pipe joint 7 is red copper;

[0095] The sectional view of the first shell 1 is as figure 2 shown;

[0096] The first graphite sleeve is a graphite sleeve with three stepped holes that are concave and not through, and the diameter of the first stepped hole is equal to the outer diameter of the first sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com