Triode triangle forming machine

A triangle and triode technology, applied in the field of triode triangle forming machines, can solve problems such as inability to adapt, the difficulty of inserting the three electrodes of the triode, and affecting the production progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

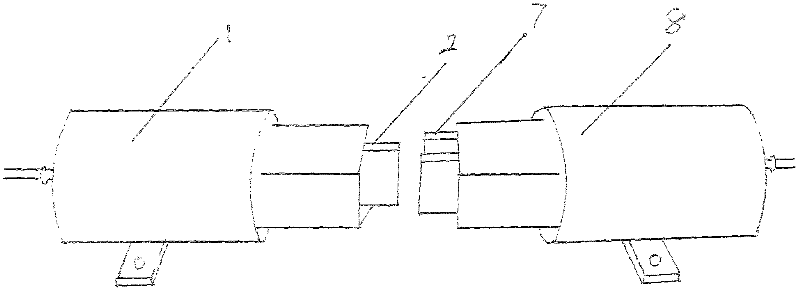

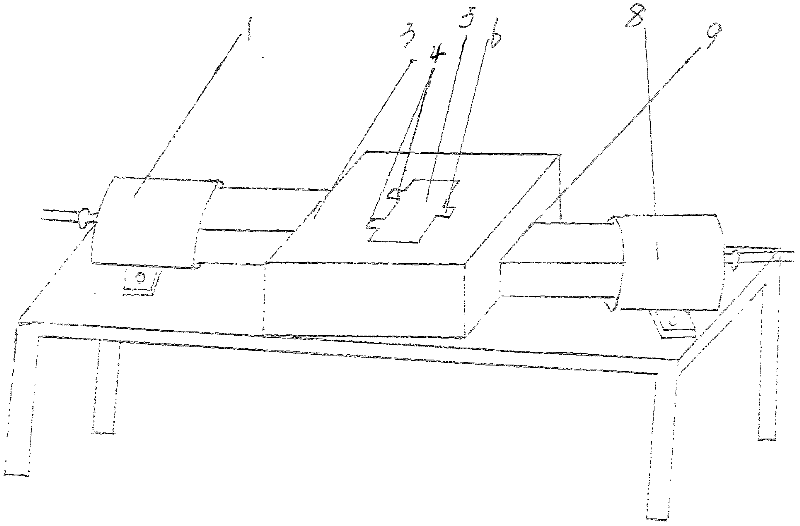

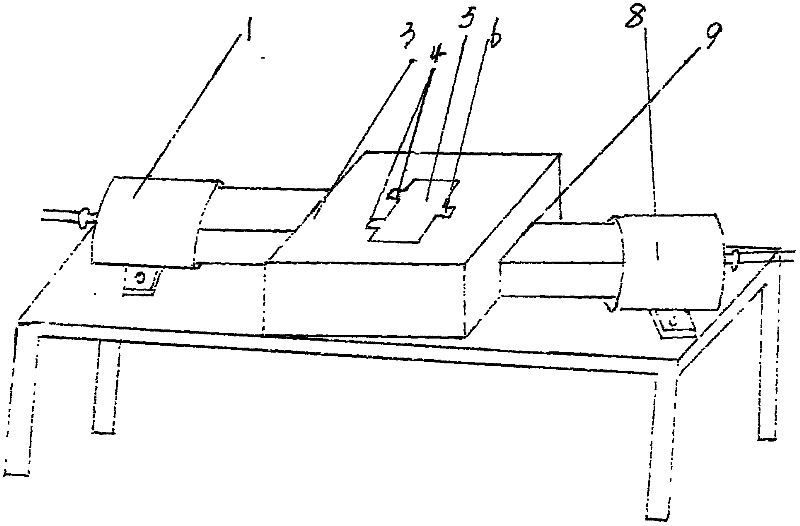

[0013] The specific implementation method of the present invention will be further described in detail below in conjunction with the accompanying drawings

[0014] The purpose of the present invention is exactly to form three electrodes arranged in a line on the triode into a triangular arrangement of the finished product, so at first the triodes of the same model must be selected and placed on the same machine for molding. When operating, the telescopic strokes of the telescopic rods on the two pneumatic actuators must be adjusted first. The adjustment is appropriate so that the three convex blocks at the front end of the front telescopic rod just fit into the three grooves on the left and right sides of the rectangular square hole. The three convex top blocks at the front end are exactly on the same plane as the left and right planes of the rectangular square hole, then insert the triode through the rectangular square hole, slowly turn on the air control switch, and let the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com