A fuel assembly lower nozzle for balancing the flow of coolant at the core inlet

A technology for fuel assemblies and balancing cores, which is applied to reactor fuel elements, reactors, and greenhouse gas reduction, etc., can solve the problems of increasing fuel rod vibration and wear loss and easy to generate lateral flow, etc., so as to reduce the risk of vibration and wear and achieve uniform flow. , reduce the effect of lateral flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

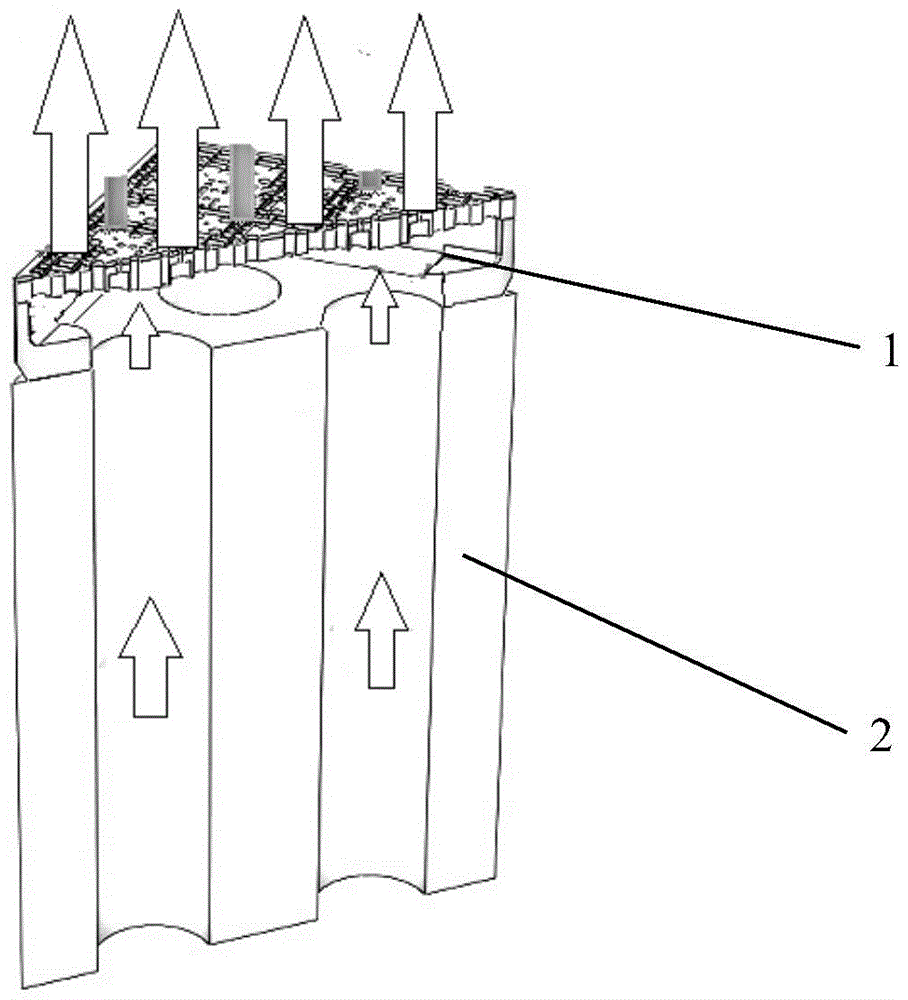

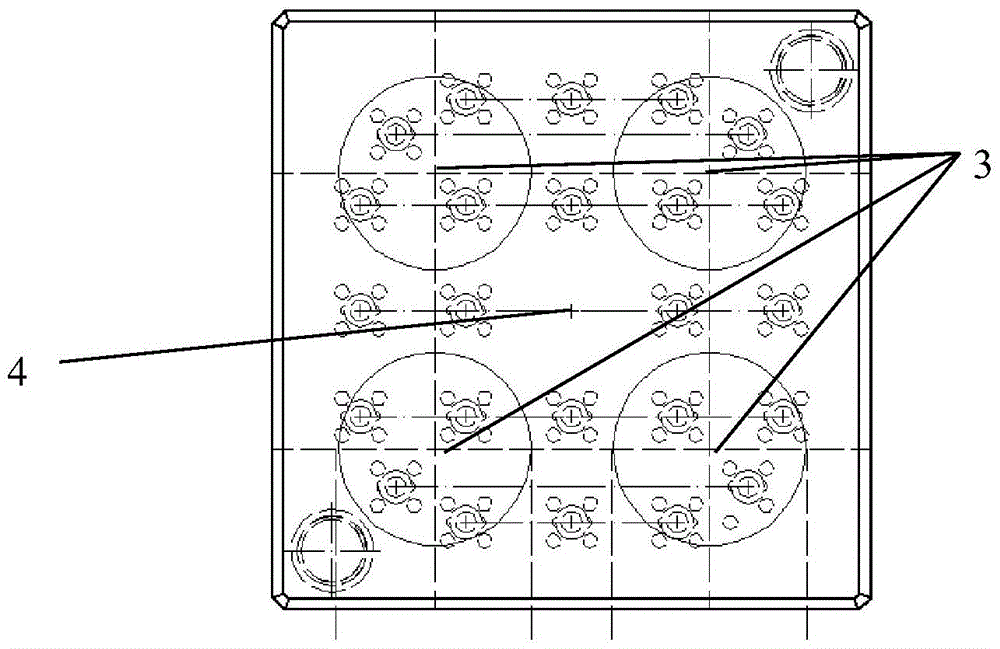

[0039] Such as Figure 4 and Figure 5 As shown, the lower pipe seat 1 of the preferred embodiment of the present invention is composed of a square filter plate 5 , a lower grid plate 6 and a support frame 7 . Wherein the uppermost filter plate 5 mainly plays the role of filtering foreign matter, and is manufactured by plate machining or plate stamping. The filter plate 5 is composed of a frame, a round hole plate, a slat, etc. The periphery of the frame of the filter plate 5 matches the size of the lower grid plate, and is a square with a side length of about 180mm-220mm, a frame width of about 5-10mm, and a thickness of about 0.5mm. ~2mm. The circular hole plate of the filter plate 5 is divided into 9 pieces, and each piece is distributed with a circular hole with a diameter of about 5-7mm. The circular hole plays the role of preventing foreign matter on the one hand, and controls the flow , The thickness of the round hole plate is about 0.5 ~ 2mm. The slats of the filte...

Embodiment 2

[0043] Such as Figure 7 As shown, the lower nozzle base 1 of the preferred embodiment of the present invention is composed of a lower grille 6 , a support frame 7 , and a filter strip 9 .

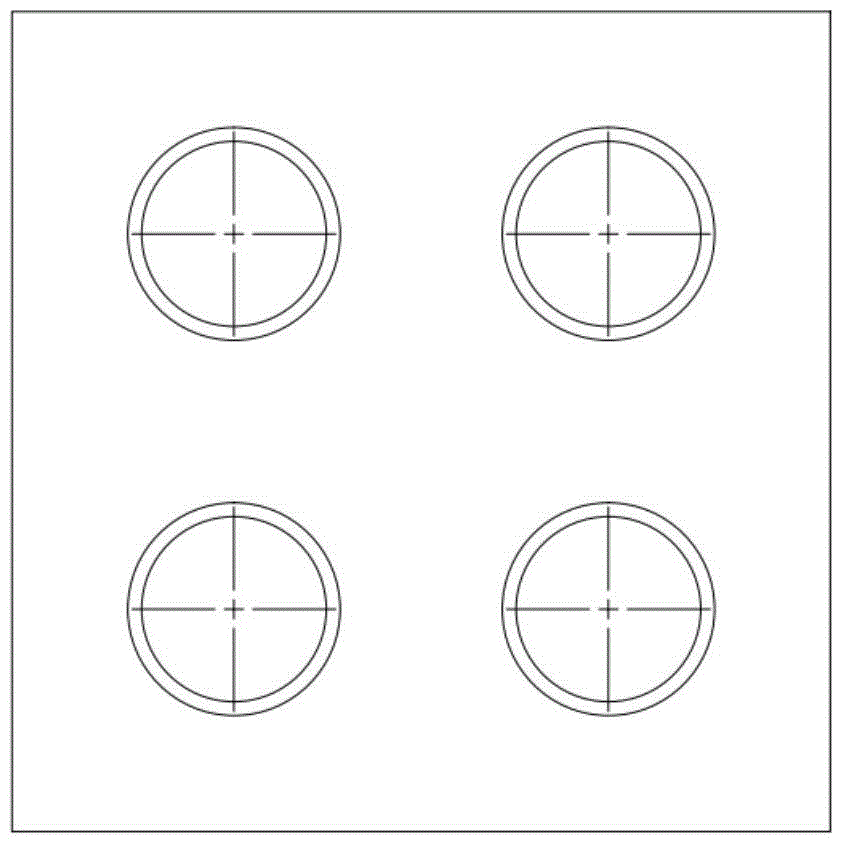

[0044] Wherein the lower grille 6 is manufactured by plate machining, is a square with a side length of about 180 mm to 220 mm, and a thickness of about 15 to 25 mm. The lower grille 6 is machined with circular water holes 8 with different apertures. Such as Figure 6 As shown, the flow hole 8 has three different pore diameters. The flow hole 8 with a smaller pore diameter is set at the corresponding position of the large flow area 3, and the pore diameter is about 5-7mm; the pore diameter is larger at the corresponding position of the large flow area 4 A flow hole 8 with a diameter of about 9-14 mm; a flow hole 8 with a diameter of about 7-9 mm is set at the junction of these two regions. The filter strip 9 is manufactured by strip machining or stamping. The thickness of the filter stri...

Embodiment 3

[0048] The difference between this embodiment and Embodiment 2 lies in that the thickness of the lower grid plate 6 is different. The lower grille 6 adopts different thicknesses in different areas. Such as Figure 8 As shown, the lower grille 6 adopts a larger thickness, about 22-26 mm, at the corresponding position of the larger flow area 3, and adopts a smaller thickness, about 18-22 mm, at the corresponding position of the lower flow area 4. The lower grille 6 with the above structure not only improves the supporting strength, but also realizes the function of optimizing flow distribution. Thicker areas can adopt trapezoidal and circular structures as shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com