Hub flange cleaning machine

A hub flange and cleaning machine technology, applied in the cleaning machine field, can solve the problems of low cleaning cleanliness, complex equipment structure, and low cleaning efficiency, and achieve the effects of improving cleaning effect, simplifying structure, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

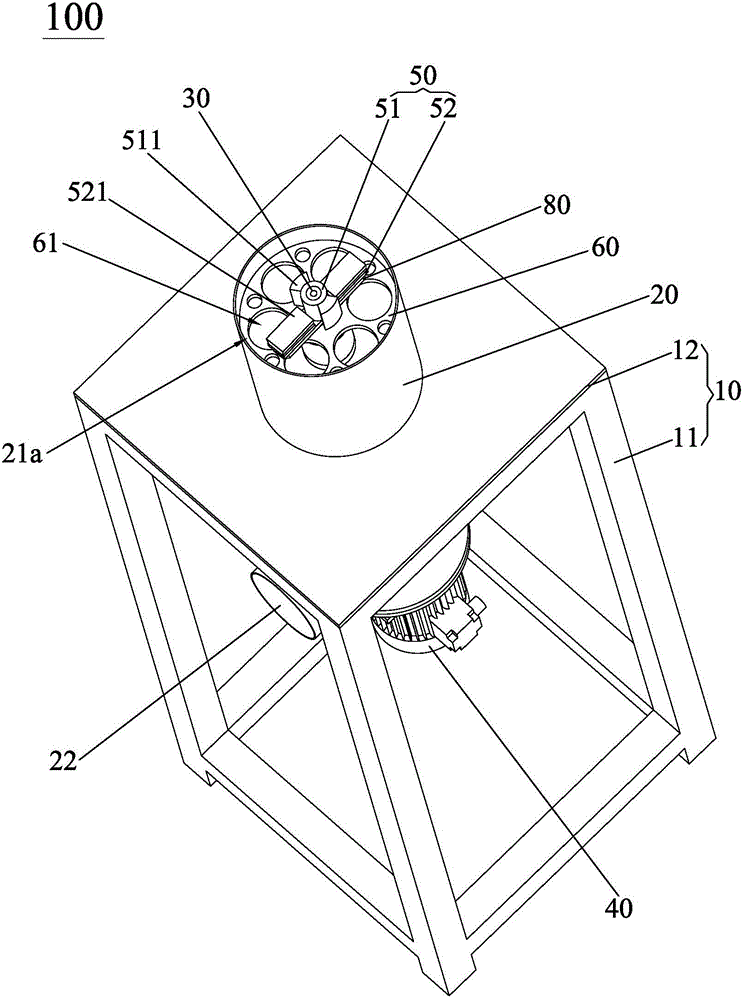

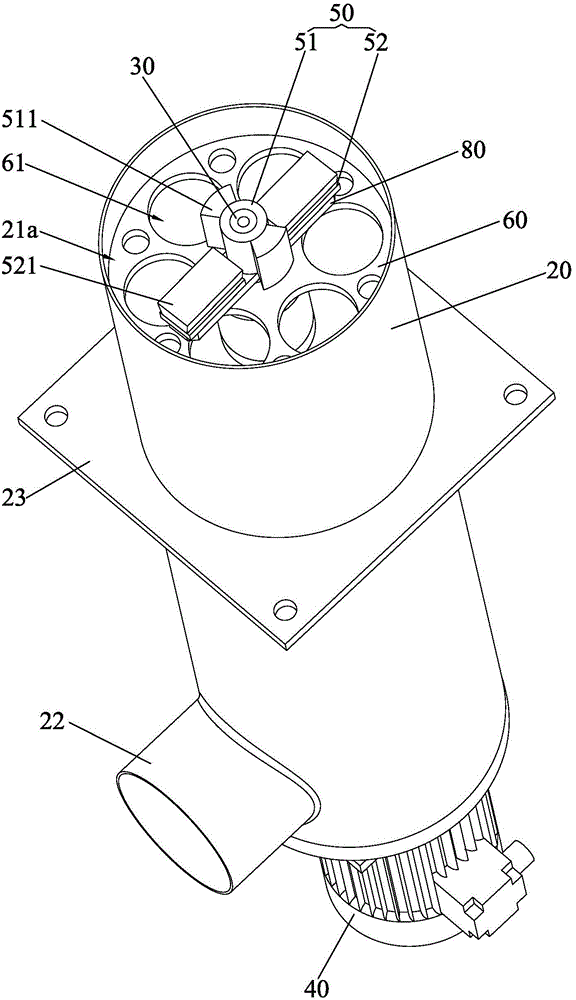

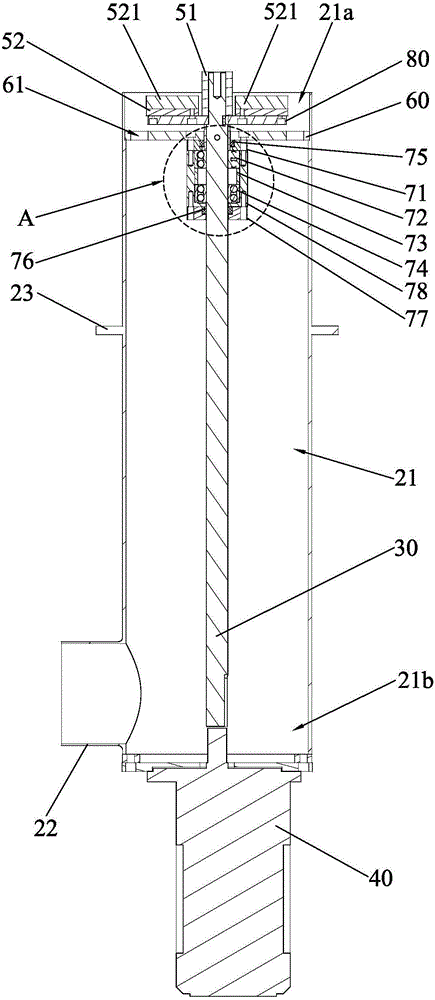

[0024] see figure 1 , figure 2 and Figure 5 , the hub flange cleaning machine 100 of the present invention is used to clean the hub flange 200, specifically, in this embodiment, the hub flange cleaning machine 100 of the present invention is used to clean the end face 210 and The hole wall of the central hole 220 is cleaned to remove impurities such as dust on the end face 210 of the hub flange 200 and the hole wall of the central hole 220, but do not limit the hub flange cleaning machine of the present invention by taking this example 100 AoE.

[0025] Wherein, the hub flange cleaning machine 100 of the present invention includes a frame 10 , a bobbin tube 20 with a hollow structure, a rotating shaft 30 , a driver 40 and a cleaning member 50 for cleaning th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com