Automatic code printing equipment

A technology of automatic coding and equipment, applied in printing, stamping and other directions, can solve the problems of increasing production costs and high prices of enterprises, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

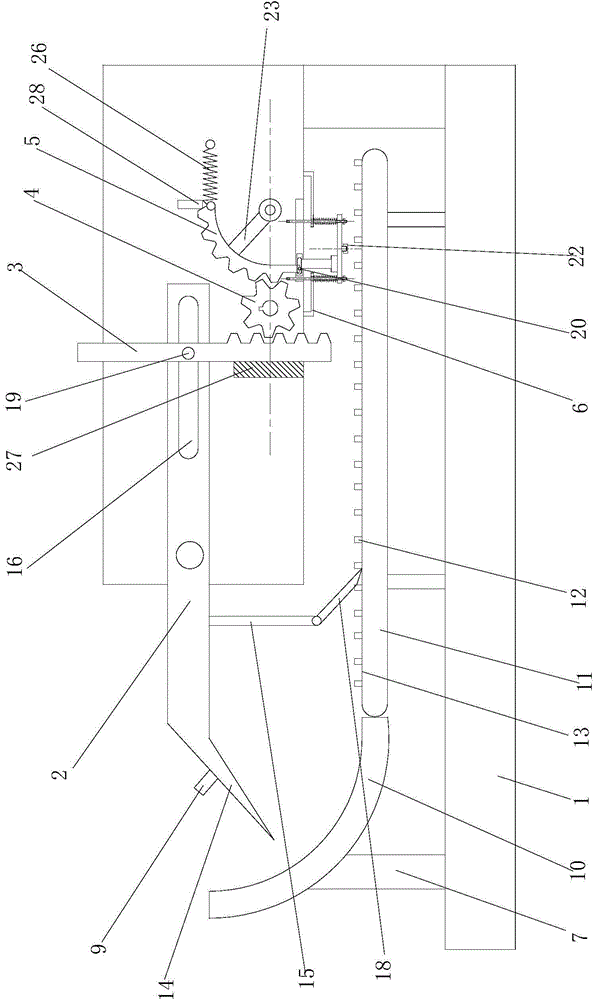

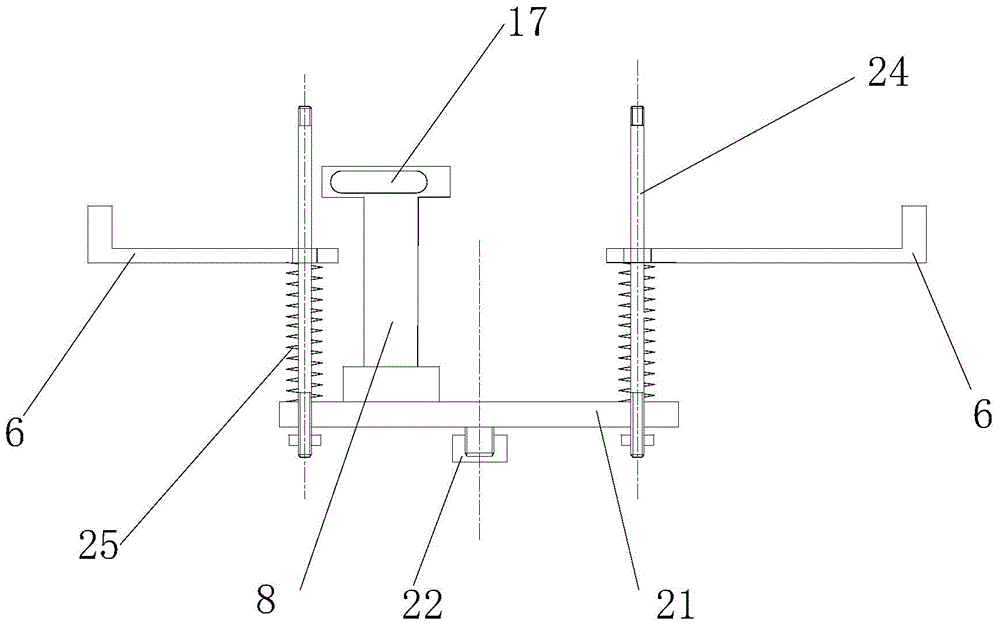

[0019] As shown in the figure, the automatic coding equipment of the present invention includes a base 1, a rotating rod 2, a linear rack 3, a gear 4, an arc rack 5, an L-shaped bracket 6 and a push rod 8. The base 1 A guide rail 10 and a workbench 11 for sliding and blanking of the commodities 9 are connected through the bracket 7, and a conveyor belt 13 for moving the commodities 9 is laid on the workbench 11, and the conveyor belt 13 is provided with bumps 12 for separating the commodities 9; The rotating rod 2 is hinged on the base 1, the left end of the rotating rod 2 is provided with an inclined platform 14 for the commodity 9 to fall into the guide rail 10, the left end of the rotating rod 2 is provided with an extension rod 15, and the lower end of the extension rod 15 is hinged for pushing The conveyor belt 13 moves the connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com