Heat insulation aluminum plate for automobile exhaust pipe

A technology of automobile exhaust and aluminum plate, applied in the field of auto parts, can solve the problem of no sound absorption, and achieve the effect of increasing rigidity, saving cost and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

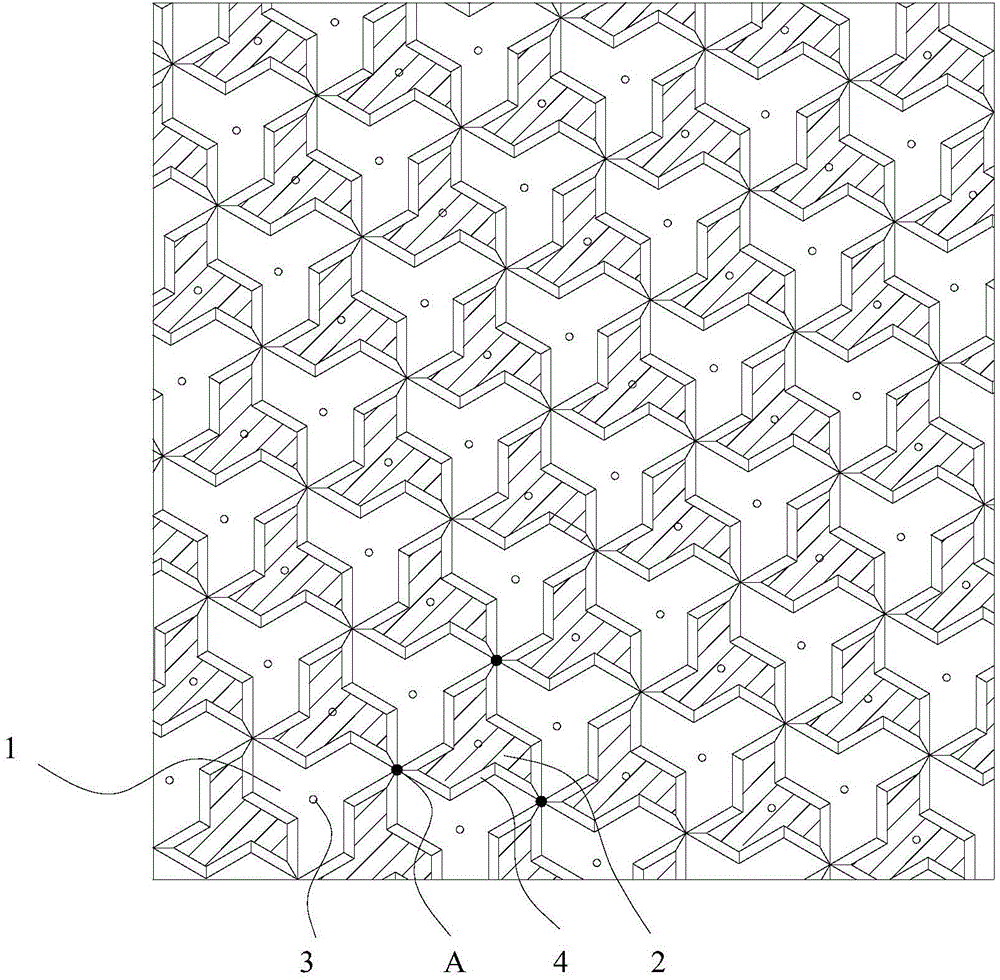

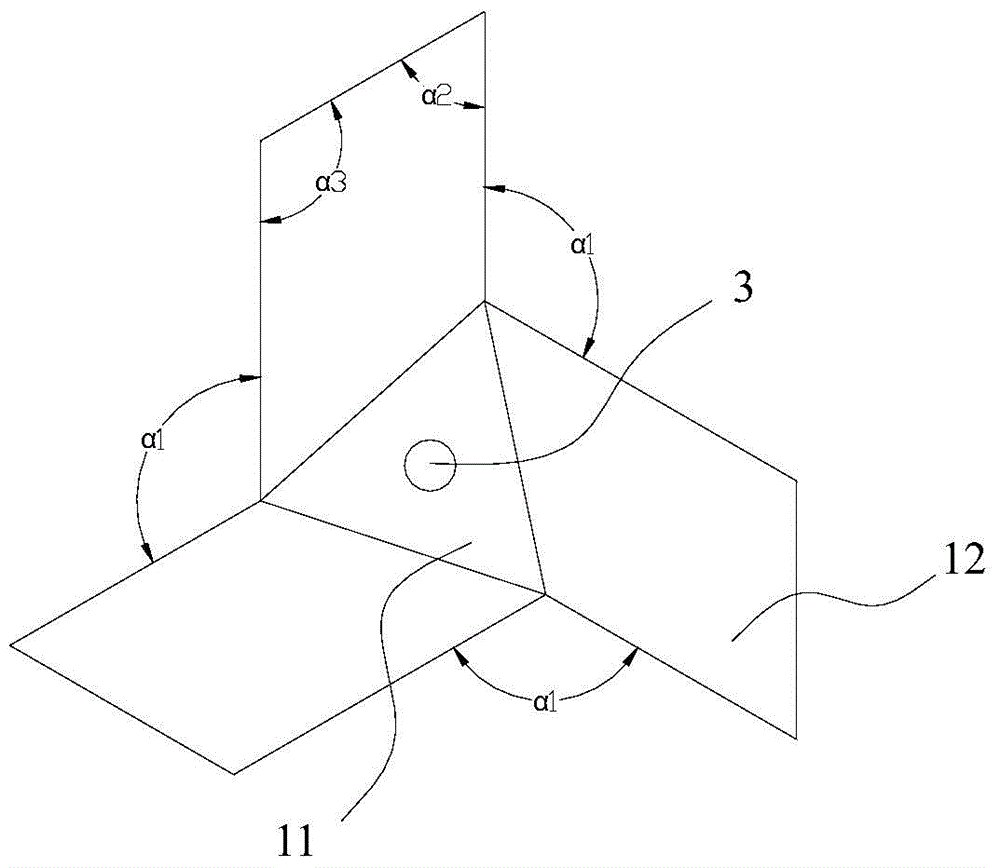

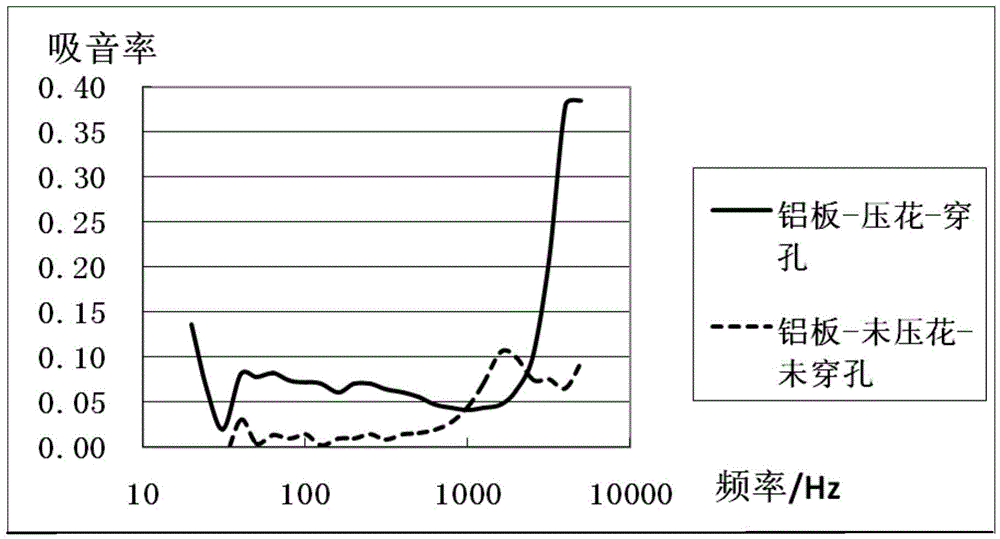

[0026] Such as figure 1 As shown, the heat-insulating aluminum plate used for automobile exhaust pipes includes a plurality of convex parts 1 and concave parts 2, and the convex parts 1 and concave parts 2 are arranged alternately in sequence, and each convex part and each concave part is provided with a micro-perforation 3 , the diameter of the micro-perforation 3 is 0.2mm-1mm. figure 1 The ones without hatched lines are the convex parts 1, and the ones filled with diagonal dashed lines are the concave parts 2. The convex parts 1 and the concave parts 2 are arranged alternately and at intervals in sequence to form a continuous concave-convex embossed structure. In the present invention, the convex part 1 and the concave part 2 are relative concepts, from figure 1 Viewing from the angle of view, the convex part 1 is convex upwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com