Integral floor bearing damping structure for rail transit vehicles such as high speed trains and metros

A technology for rail transit vehicles and high-speed trains, which is applied in the field of the overall floor-bearing vibration-damping structure, can solve the problems of a large number of shock absorbers, low installation efficiency, long working hours, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

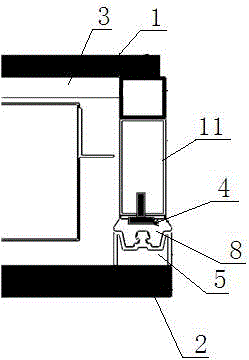

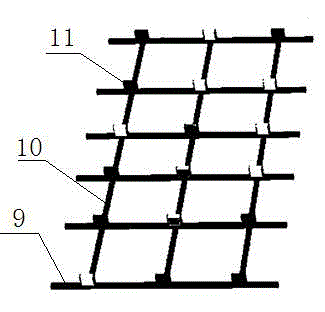

[0015] refer to Figure 1-Figure 3 , the rail transit vehicle such as high-speed train, subway etc. of the present embodiment uses the floor overall load-bearing damping structure, and the upper end is connected with floor 1 by screw, and the lower end is connected with the car body underframe 2 of EMU, and it comprises reinforcing beam 3, shock absorber 4. Mounting seat 5, the mounting seat 5 is fixedly installed on the vehicle body chassis 2, the bottom of the shock absorber 4 is installed in the mounting seat 5, and the shock absorber 4 and the mounting seat 5 are connected by a buckle, so The top of the shock absorber 4 is fixedly connected to the reinforcement beam 3 through bolts 7, and the reinforcement beam 3 is connected to the floor 1 through screws.

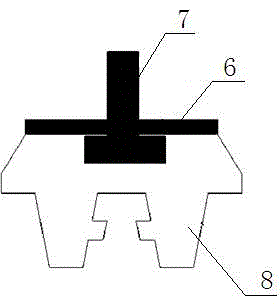

[0016] The shock absorber includes a top plate 6, bolts 7, and a vulcanized rubber body 8. The top plate 6 vulcanizes the top of the rubber body 8. The bolt 7 and the top plate 6 are welded together and embedded in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com