Subframe for a motor vehicle

A technology for subframes and motor vehicles, which is applied to power units, vehicle components, substructures, etc., can solve problems such as being unable to be utilized or making full use of mass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

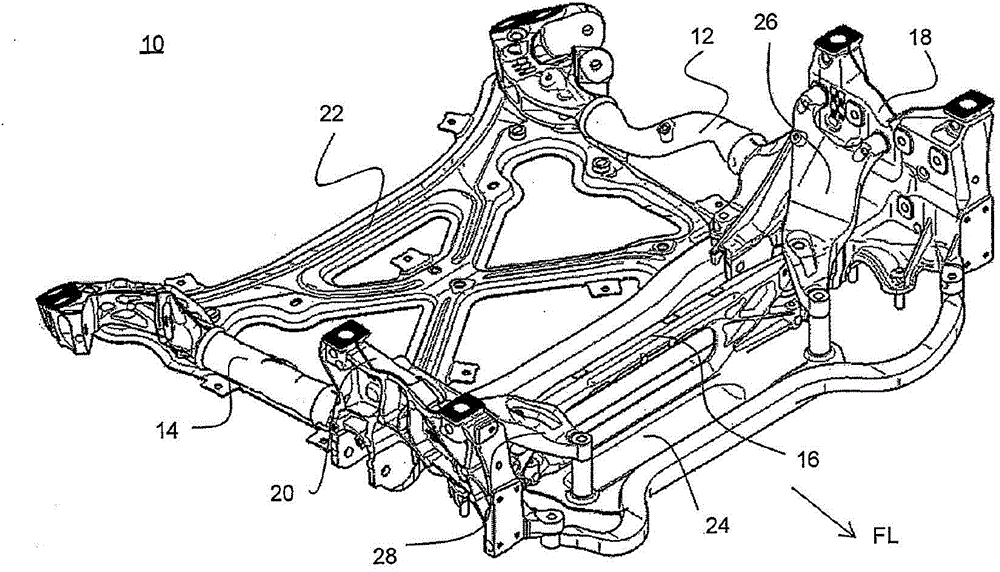

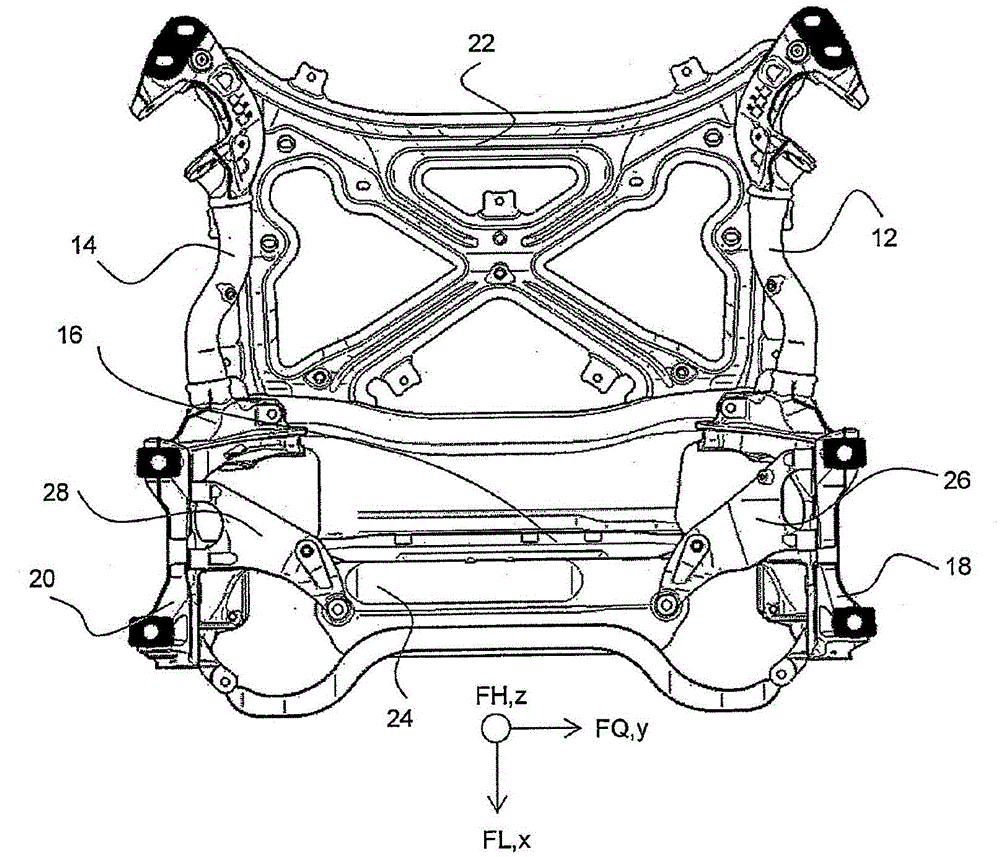

[0028] figure 1 with figure 2 A subframe for a motor vehicle is shown, generally designated by the reference number 10 .

[0029] The subframe 10 essentially has a first longitudinal member 12 oriented in the vehicle longitudinal direction FL, a second longitudinal member 14 oriented in the vehicle longitudinal direction FL, and a cross member 16 extending in the vehicle transverse direction FQ.

[0030] The two longitudinal beams 12 , 14 and the transverse beam 16 are fixedly connected to one another via first and second cast joints 18 , 20 . In addition to the cross member 16 , the subframe 10 also has a reinforcement structure 22 and a thrust area 24 as further transverse structures.

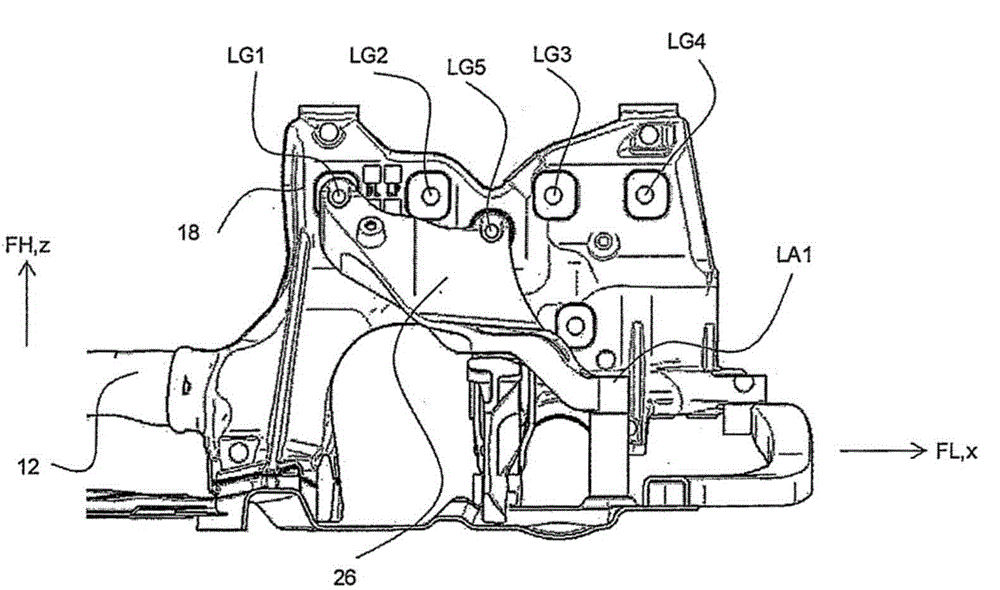

[0031] to accommodate figure 1 In the power unit, which is not shown for the sake of clarity, there are a plurality of casting joints 18, 20, especially made of image 3 Bearing connection points LG1 , LG2 , LG3 , LG4 and LG5 are shown for fastening the engine mount.

[0032] In additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com