Non-threading knitting machine spindle

A knitting machine and spindle technology, which is applied to braided fabrics, textiles, and papermaking, can solve the problems of long threading time, low efficiency, troublesome threading, etc., and achieve the effect of convenient threading, saving threading time, and simple threading method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

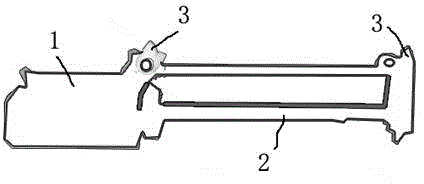

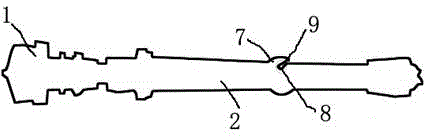

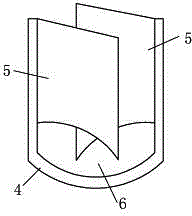

[0013] Combine below Figure 1 to Figure 4 Specific description embodiment:

[0014] like Figure 1 to Figure 4 As shown, the spindle of the non-threading knitting machine includes a front end part 1 and a wire inlet part 2, and an opening porcelain eye 3 is respectively provided at both ends of the wire inlet part 2, and the opening porcelain eye 3 includes a U-shaped body 4. There is a baffle 5 on the two inner walls of the U-shaped body 4, and the two baffles 5 are arranged in parallel and opposite each other. There is a gap 6 between the bottom of the baffle 5 and the U-shaped body 4; the incoming line The middle of the part 2 is provided with an arc-shaped convex portion 7, and the middle of the arc-shaped convex portion 7 is provided with a wire hole 8, and the side of the arc-shaped convex portion 7 is provided with a wire inlet gap 9, and the wire inlet gap 9 communicates with the wire hole 8 .

[0015] In a preferred manner, a smooth ceramic ring 10 is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com