Imitating solid wood aluminum alloy floor adapted to mounting of multi-specification wood blocks

A technology of imitating solid wood and aluminum alloy, applied in the direction of floor, building, building structure, etc., it can solve the problems of mismatching thickness, inability to adjust the spacing of floor boards A1, and inability to properly adjust the running between the boards A1.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

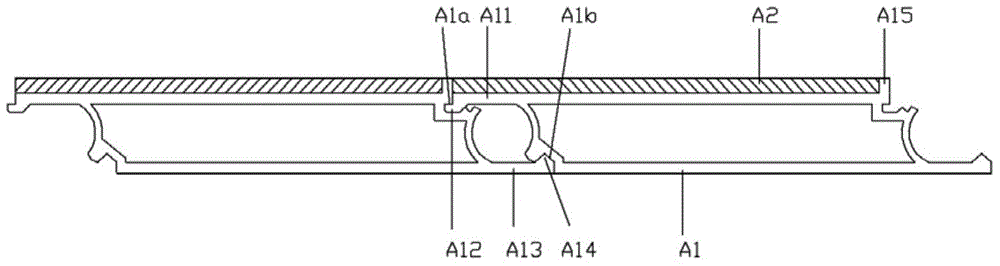

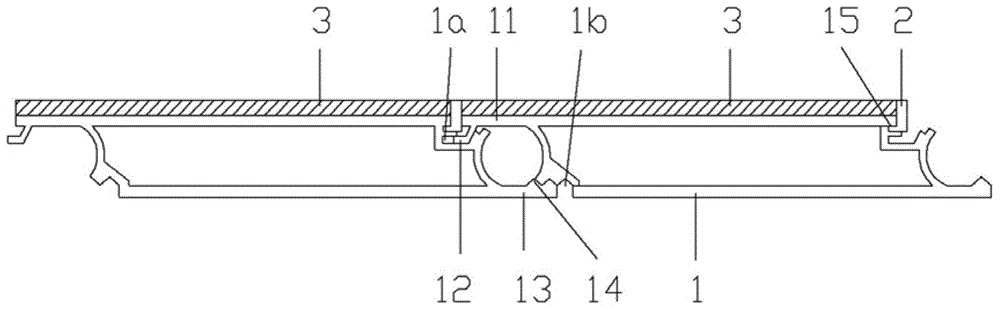

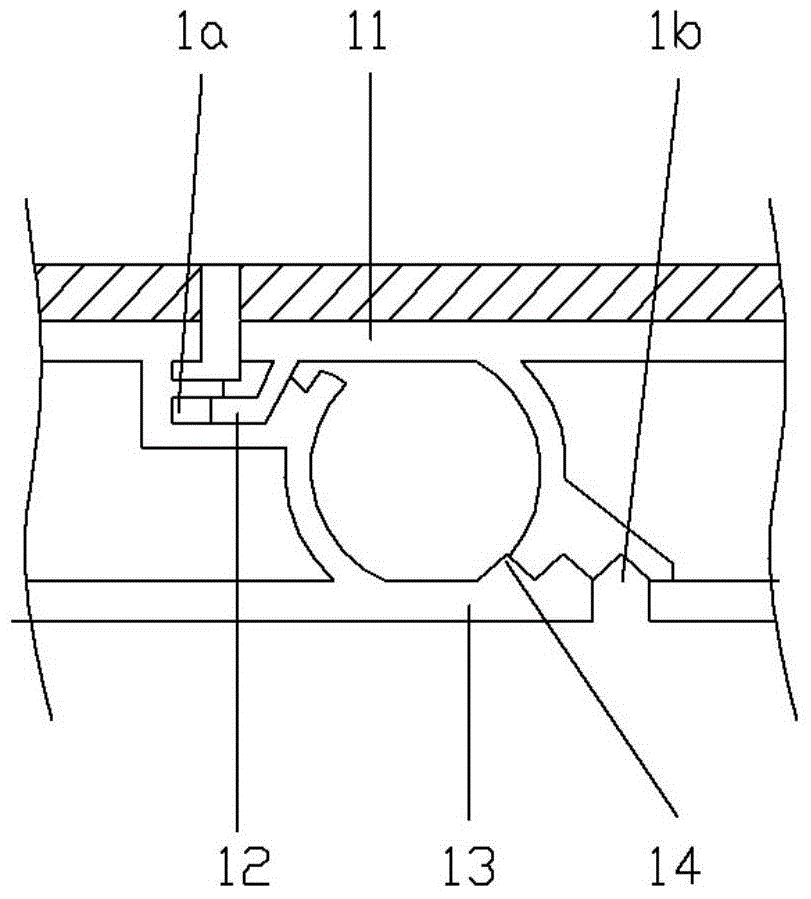

[0032] Example 1: see Figures 2 to 5 As shown, the imitation solid wood aluminum alloy floor that can be adapted to the installation of wood panels of various specifications includes a square floor panel 1, the upper left side of the floor panel 1 is extended with an upper horizontal tenon 11, and the left end of the upper horizontal tenon 11 is formed with a horizontal upper insertion Tenon 12; lower horizontal tenon 13 is extended on the lower right side of floor board 1, and vertical lower tenon 14 is formed on the right end of lower horizontal tenon 13; upper slot 1a and lower slot 1b are formed on floor board 1, adjacent Among the two floor boards 1, the horizontal upper tenon 12 of one floor board 1 is inserted into the upper slot 1a on the other floor board, and the vertical lower tenon 14 on one of the floor boards 1 is inserted into the other floor board. In the lower slot 1b on the plate 1; the vertical baffle 2 is a "7" shape, and the vertical baffle 2 is inserted ...

Embodiment 2

[0034] Example 2, see Image 6 As shown, the vertical baffle 2 is half an "I" shape. All the other are with embodiment 1.

Embodiment 3

[0035] Example 3, see Figure 7 As shown, the vertical baffle 2 is in the shape of an "F". All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com