Comprehensive testing equipment for hydraulic components of tunnel boring machine

A tunnel boring machine and comprehensive detection technology, which is applied in the direction of mechanical equipment, fluid pressure actuation system testing, fluid pressure actuation device, etc., can solve the problems that the detection of hydraulic components cannot be realized, and the detection procedures of hydraulic components are cumbersome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described in conjunction with accompanying drawing and example:

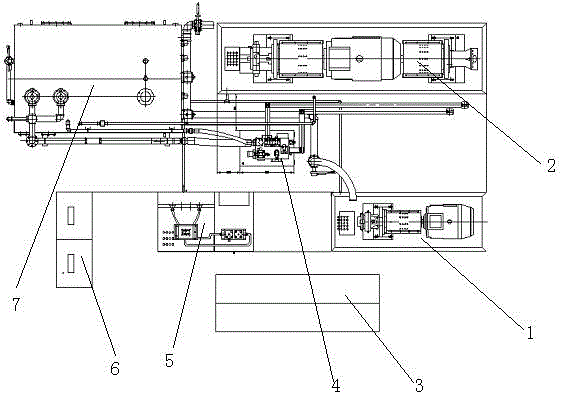

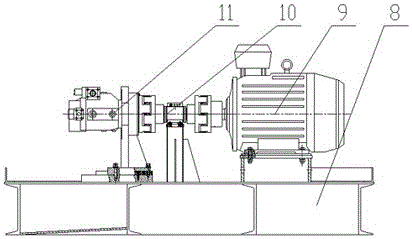

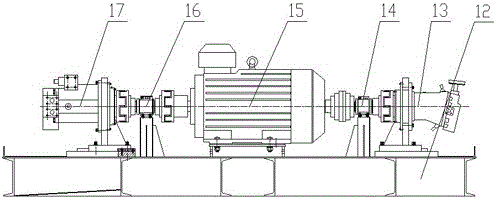

[0015] Such as figure 1 As shown, a comprehensive detection device for hydraulic components of a tunnel boring machine, the comprehensive detection device includes a comprehensive valve group 4, a PLC and an operation panel 3 for detecting the hydraulic pump, hydraulic motor, and hydraulic valve of the tunnel boring machine; Corresponding to the hydraulic pump and the hydraulic motor, there is a detection platform for detecting it, and the detection platform cooperates with the corresponding sensor on the integrated valve group 4 to complete the detection of the hydraulic pump and the hydraulic motor; There are two testing benches: small pump testing bench 1 for testing hydraulic pumps with a displacement of less than 200ml and a large pump testing bench for testing hydraulic pumps and hydraulic motors with a displacement of more than 200ml and less than 750ml Frame 2; (c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com