A pump relay mode output system and method for LNG peak regulation

An output system and peak shaving technology, applied in container filling method, container discharge method, pump and other directions, can solve problems such as BOG safety accident, pipeline cold shock, pipeline pipeline accident, etc., to solve the problem of stratification and reduce operating costs , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

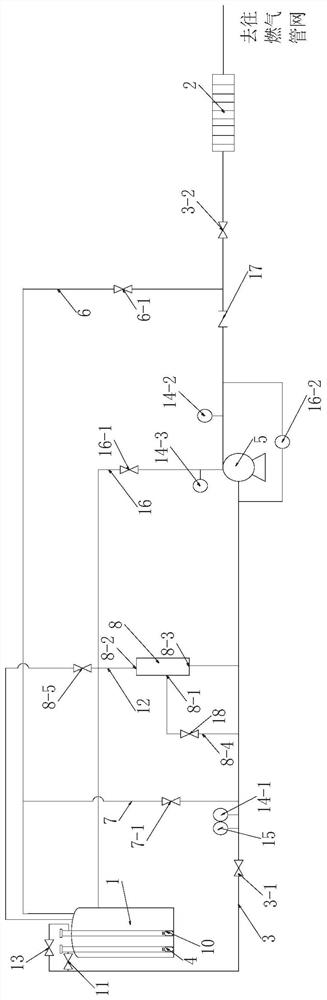

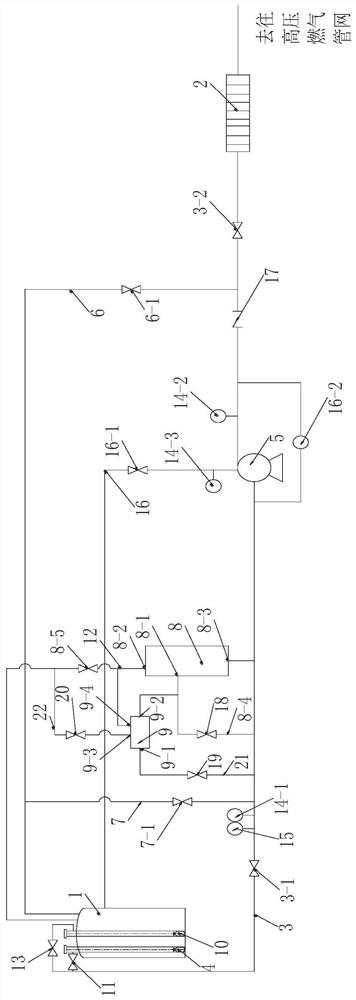

[0046] Such as figure 1 As shown, a pump relay output system for LNG peak shaving in this embodiment includes an LNG storage tank 1 and a gasification device 2, a main pipeline 3 is arranged between the LNG storage tank 1 and the gasification device 2, and a low-pressure Pump 4, high-pressure pump 5 and return device, the low-pressure pump 4 is arranged in the LNG storage tank 1, and the high-pressure pump 5 is arranged outside the LNG storage tank 1; The pump well, the low-pressure pump 4 is arranged in the low-pressure pump well, the LNG storage tank 1 protrudes from the top of the low-pressure pump well, the part protruding from the LNG storage tank 1 is connected with the main line 3, and the main line 3 is close to the part protruding from the LNG storage tank 1 A first check valve 11 is provided on the part, which can effectively prevent the backflow of the pumped liquid;

[0047] One end of the main line 3 communicates with the low-pressure pump 4, the other end of the...

Embodiment approach

[0049] The above-mentioned return device is used to return the LNG in the main line 3 to the LNG storage tank, as long as the above-mentioned functions can be realized, there is no limitation on the specific structure and connection method. As a preferred embodiment, the return device includes a pump Backflow device, the pump backflow device includes a pump back pipeline 6, one end of the pump back pipeline 6 is connected to the main line 3 and the connection point is between the high pressure pump 5 and the gasification device 2, the pump back pipeline The other end of 6 is connected to the LNG storage tank 1, and the post-pump pipeline 6 is provided with a post-pump return valve 6-1 for controlling flow. The method of backflow after the high-pressure pump can effectively realize the reflux of the LNG in the main pipeline to the LNG storage tank, and realize the matching of the flow rate of the LNG flowing out from the outlet of the high-pressure pump and the LNG pre-entering ...

Embodiment 2

[0062] A method of outputting LNG peak shaving using the pump relay mode output system for LNG peak shaving described in Embodiment 1 of this embodiment includes the following steps:

[0063] Step 1. Pre-cool the low-pressure pump pipeline, the high-pressure pump 5 and its pipeline, the ejector 8 and its pipeline. The pre-cooling process of the low-pressure pump pipeline includes: opening the first valve 3-1 and the pump front return valve 7-1, LNG is pre-cooled with a low-pressure pump 10 with a small flow rate (15m 3 / h~30m 3 / h) pump into the main pipeline 3, return to the LNG storage tank 1 through the pipeline 7 before the pump, observe the temperature and pressure in the pipeline through the first temperature sensor 14-1 and the first pressure sensor 15, when the first temperature sensor 14-1 When the displayed temperature is lower than -120°C, the precooling of the low-pressure pump pipeline is completed, and the first valve 3-1 and the pump front return valve 7-1 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com