Testing tank for temperature cycle testing machine for insulator

A temperature cycle and testing machine technology, applied in strength characteristics, measuring devices, instruments, etc., can solve problems such as cold and hot water cannot be recycled, poor detection effect, high work intensity, etc., achieve good use effect and improve reliability , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

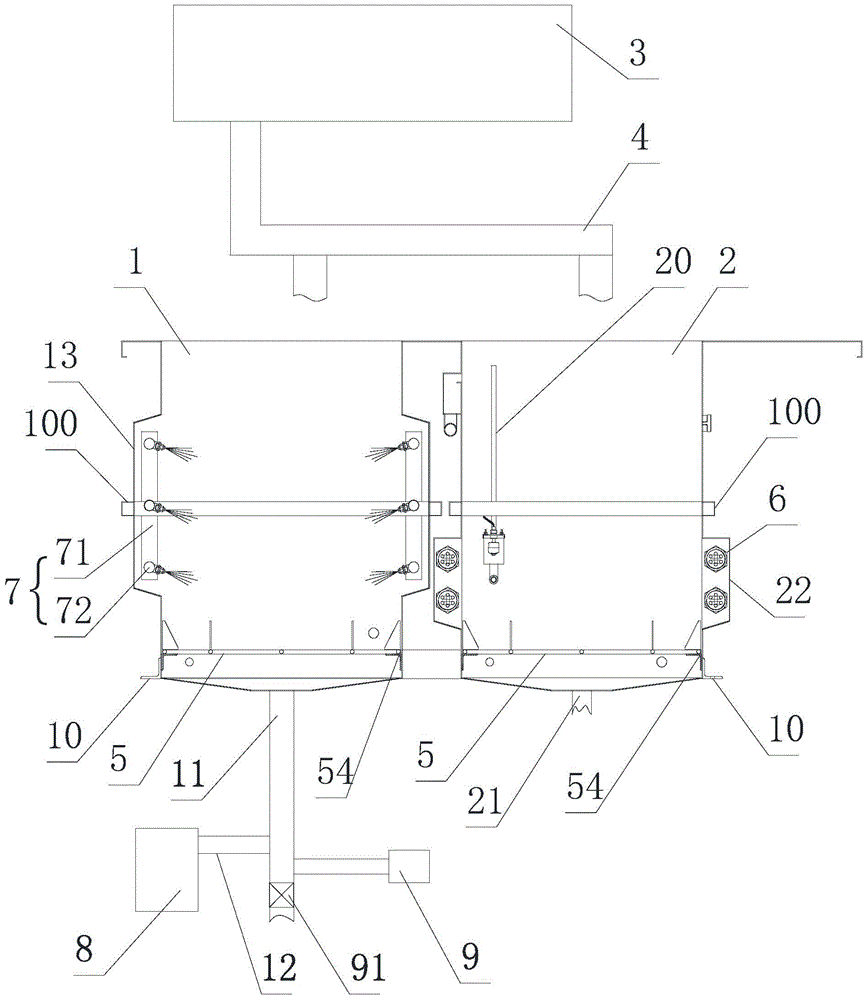

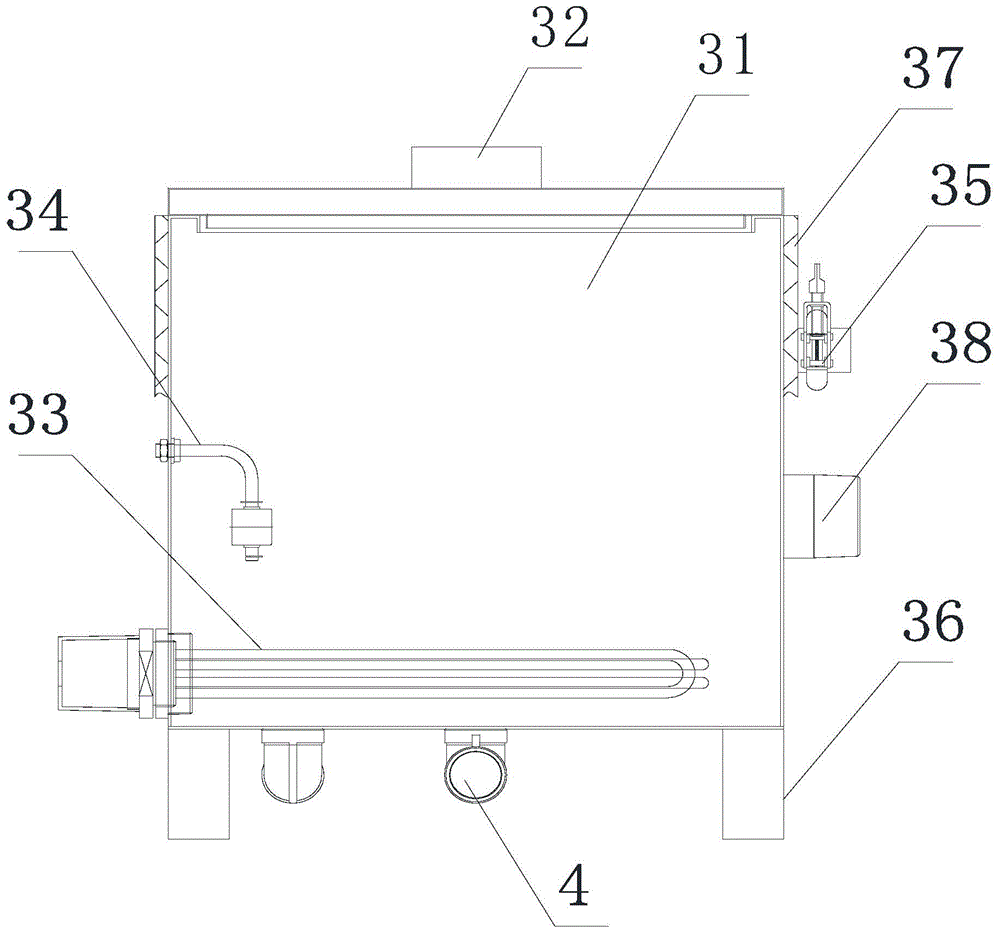

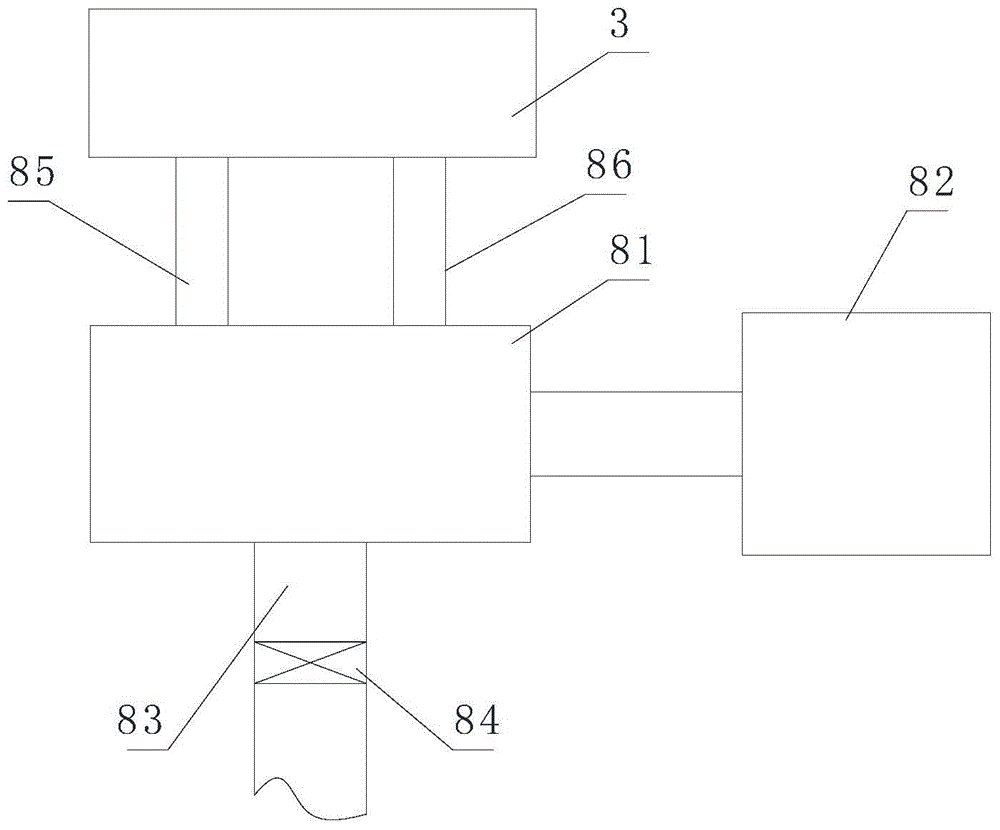

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, the test tank for insulator temperature cycle testing machine includes a first tank body 1 for cold water test and a second tank body 2 for hot water test, and is characterized in that it also includes a water tank 3, the water tank 3 is provided with a water inlet pipe 4 that facilitates water intake into the first tank body 1 and the second tank body 2, and the bottom ends of the first tank body 1 and the second tank body 2 are fixedly connected with a bracket 5. The first tank body 1 is provided with a spray assembly 7, the second tank body 2 is provided with a heating assembly 6, and the first tank body 1 is connected with a water inlet to the spray assembly 7. The water supply assembly 8, the bottom end of the first tank body 1 is provided with a first drainage pipe 11 that returns the water in the first tank body 1 to the water tank 3, and a water supply pipe 11 is provided on the first d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com