Model detection technology based complicated electromechanical system reliability assessment method

A technology of electromechanical system and model detection, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as inability to help research on fault causes and their relationship, inaccurate causal relationship of fault events, complex tree building process, etc. , to achieve the effect of simplifying the reliability evaluation process, accurate and reliable solution results, and simplifying the system modeling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below, which is an explanation rather than a limitation of the present invention.

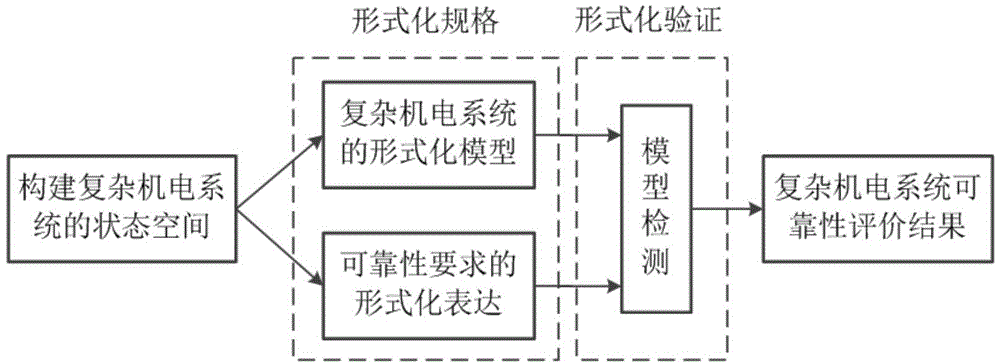

[0025] see Figure 1 to Figure 3 As shown, the present invention is a method for evaluating the reliability of complex electromechanical systems based on model detection technology. By establishing a formalized model for reliability analysis of complex electromechanical systems and a formal specification of reliability indicators, formal verification is carried out through model detection tools. It can realize the reliability assessment of complex electromechanical systems, including the following steps:

[0026] 1) Construct the state space of complex electromechanical systems

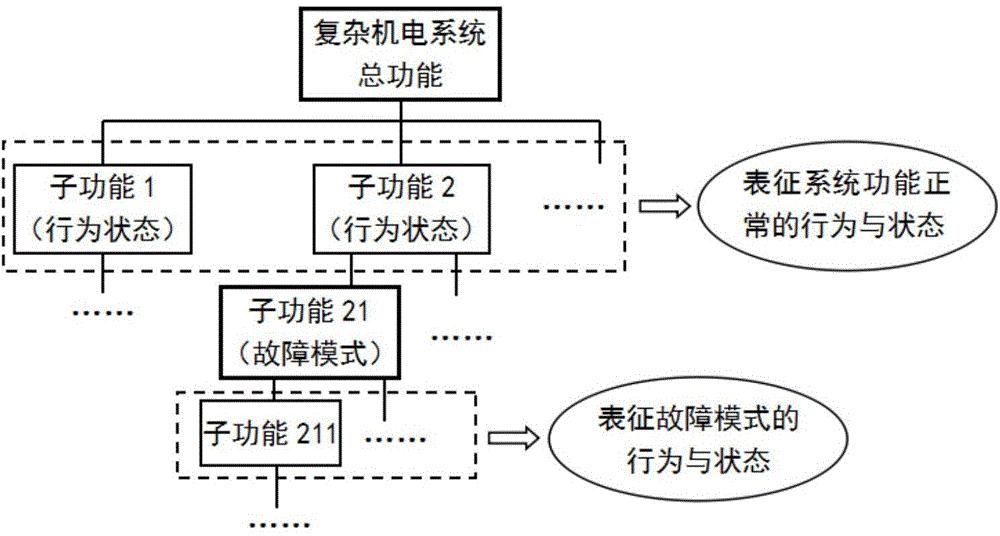

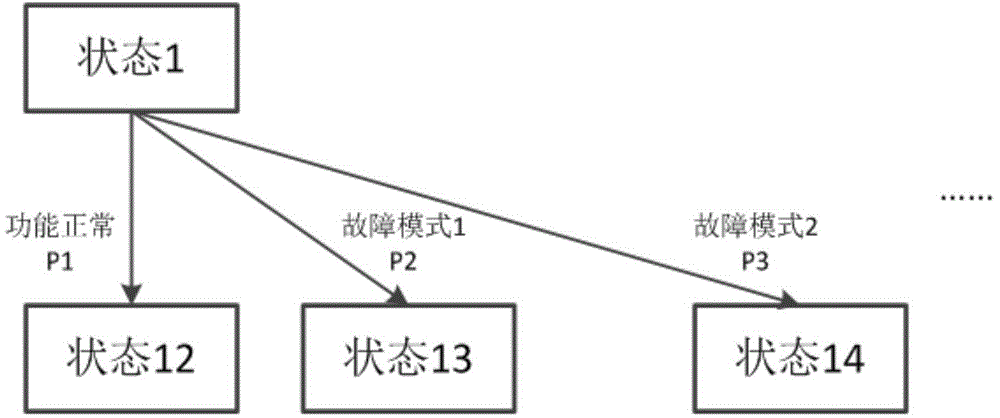

[0027] 1.1) According to the Function-Behavior-State (FBS, Function-Behavior-State) modeling theory, the function is realized by the behavior of the system, and the behavior can be discretized into a series of states of the system and their transitions. For thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com