Assembling tool for valve locking block

A valve lock and block assembly technology, used in metal processing, manufacturing tools, metal processing equipment and other directions, can solve the problems of low assembly success rate, difficulty in pressing in place at one time, difficulty, etc., to reduce labor intensity and improve production. Efficiency and product assembly quality, the effect of reducing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

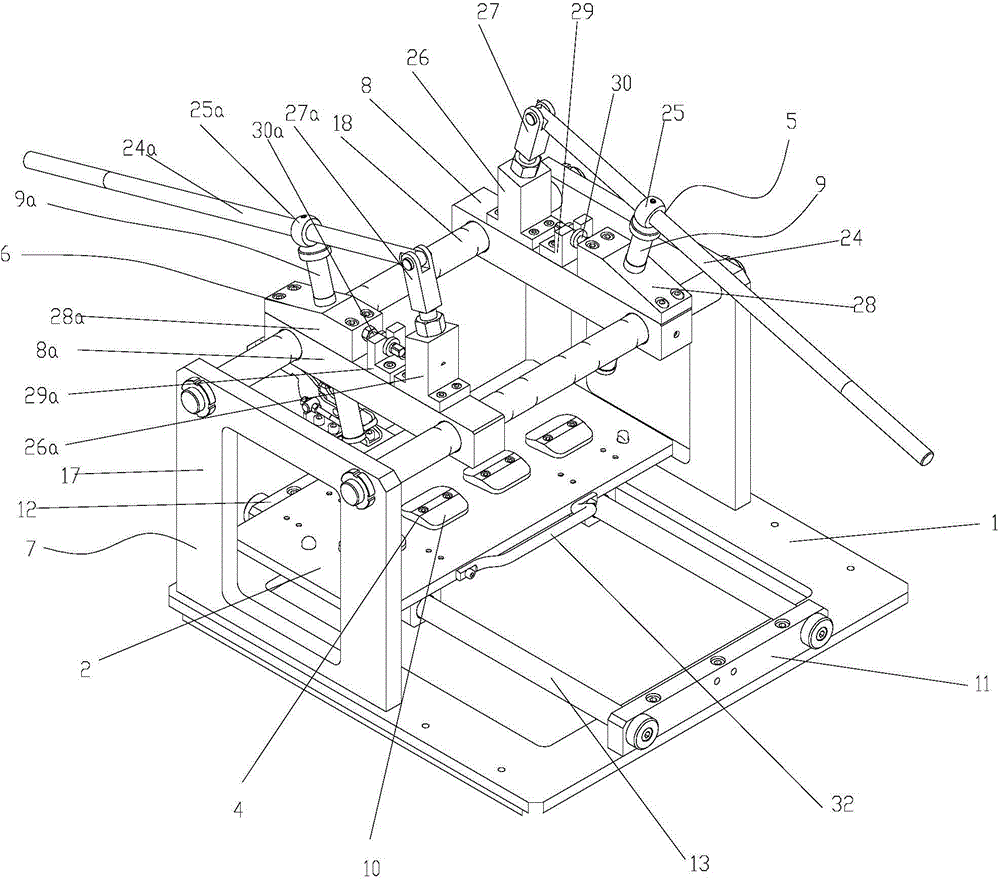

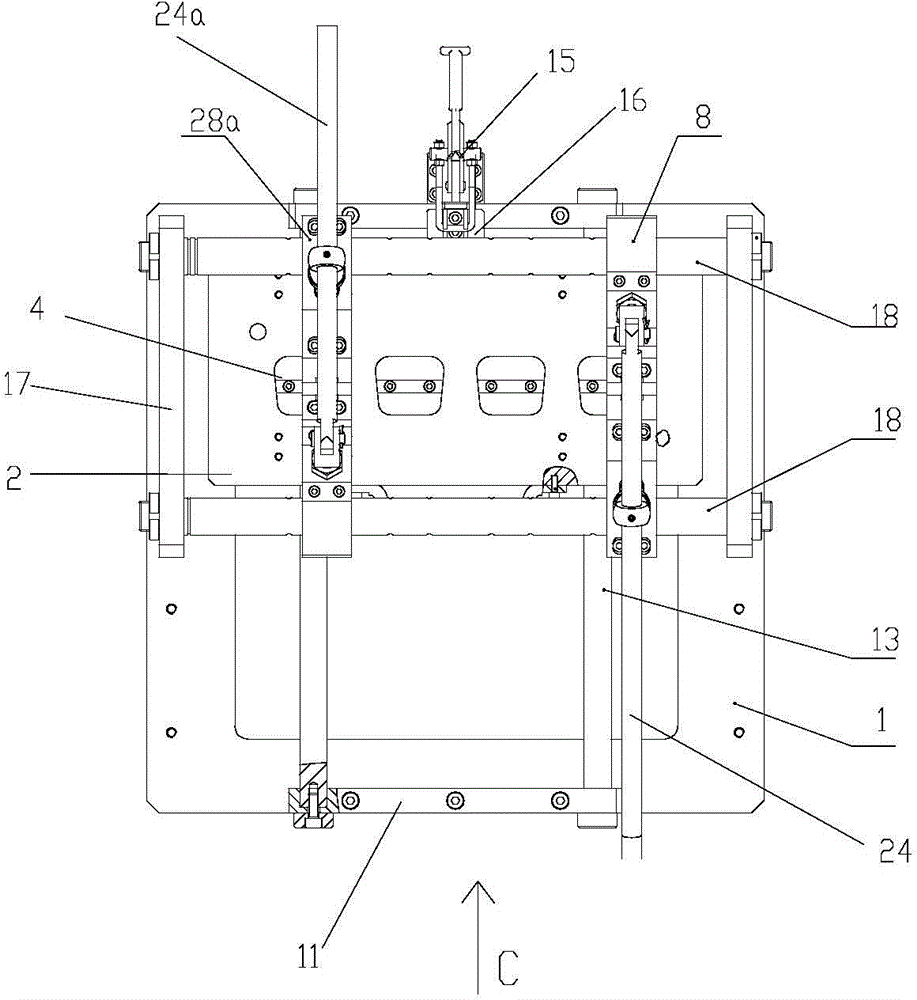

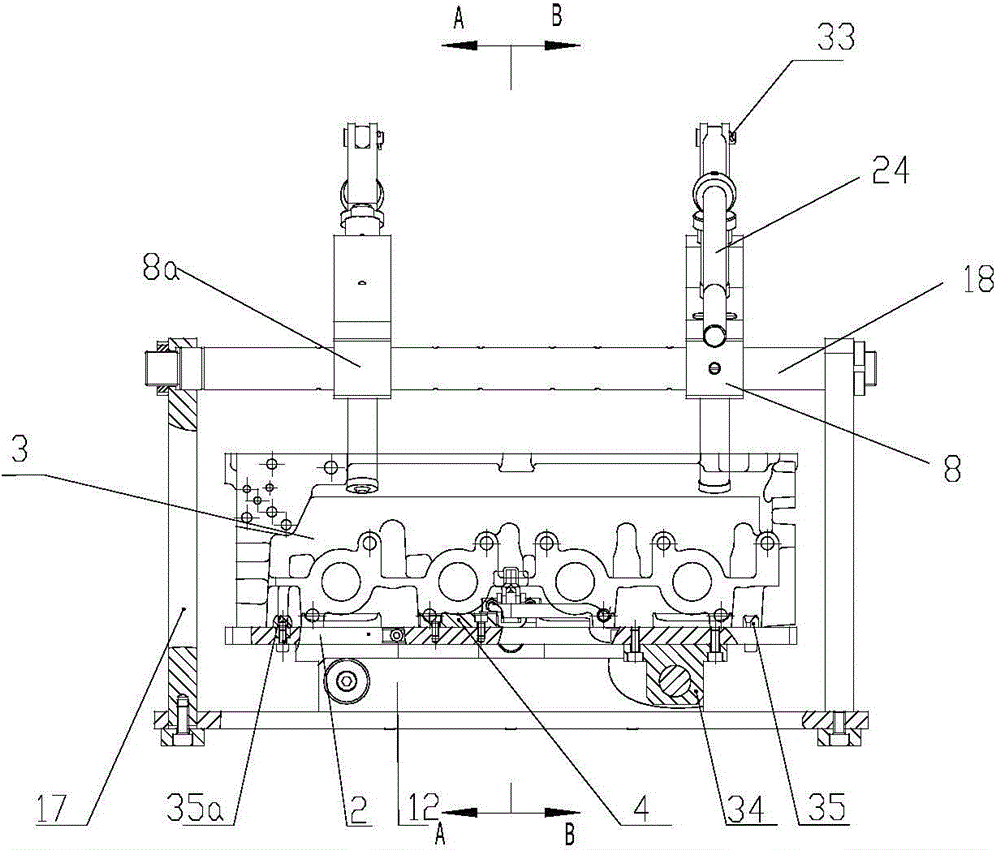

[0023] As shown in the figure: the valve lock block assembly tooling of this embodiment includes a base plate 1, a workpiece positioning support plate 2 and a valve lock block press-fit assembly, and the workpiece positioning support plate 2 is provided with a The chamber forms a cushion block 4 for adaptive support, and the valve press-fit assembly includes a support frame and an exhaust valve lock block press-fit assembly 5 and an intake valve lock block press-fit assembly 6 fixedly arranged on the support frame. The support frame 7 is fixedly arranged on the base plate 1, and the press-fit assembly 5 of the exhaust valve lock block has the same structure as the press-fit assembly of the intake side valve, and both include a base slider (base slider 8 in the figure). and base slide block 8a), pressure head assembly (in the figure, pressure head assembly 9 and pressure head assembly 9a) and a lever drive mechanism for driving the pressure head assembly to press-fit the lock bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com