Automatic caching mechanism

A technology of automatic buffering and lifting mechanism, applied in the directions of sending objects, thin material handling, transportation and packaging, etc., can solve the problem of no product disclosure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

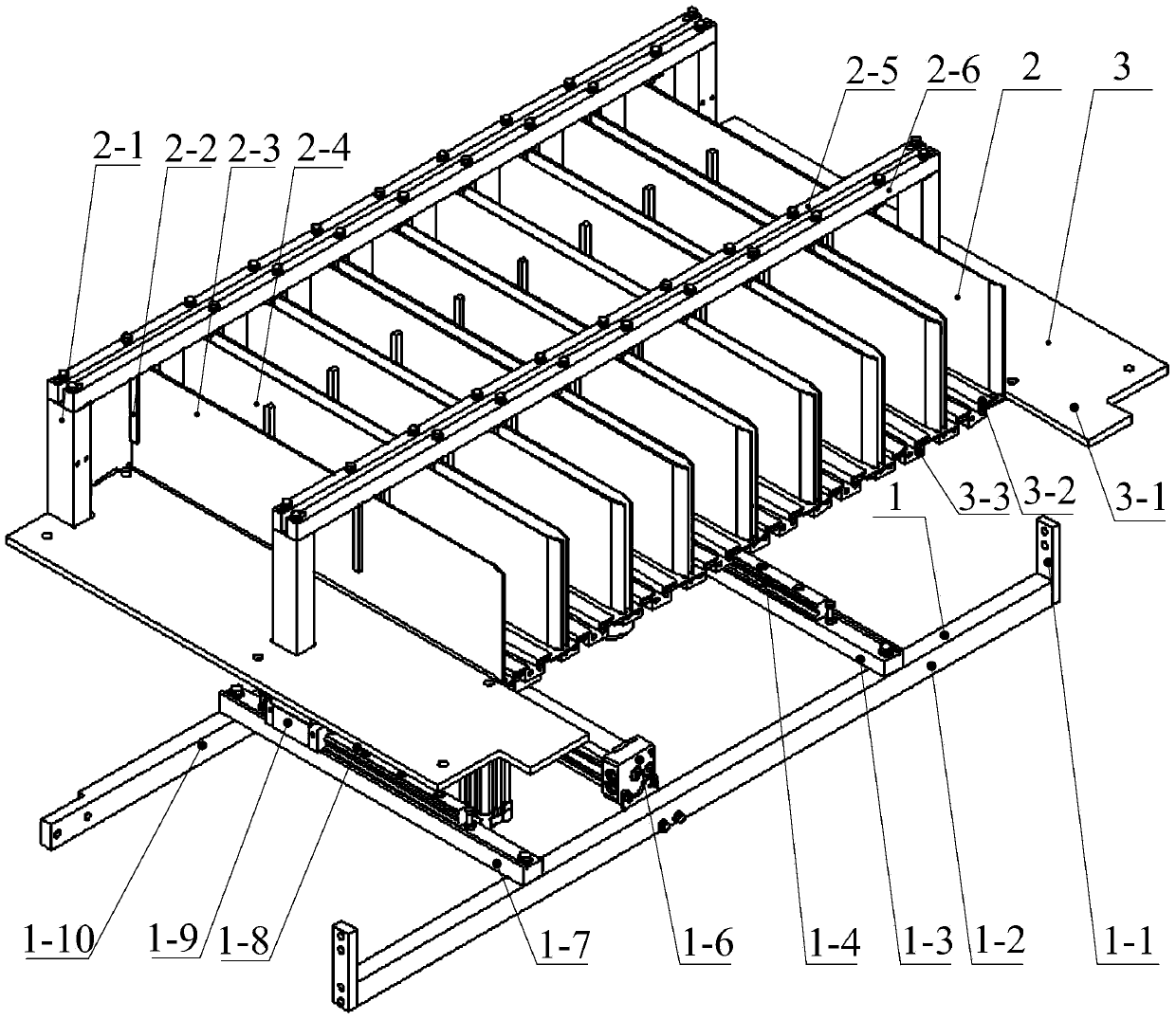

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

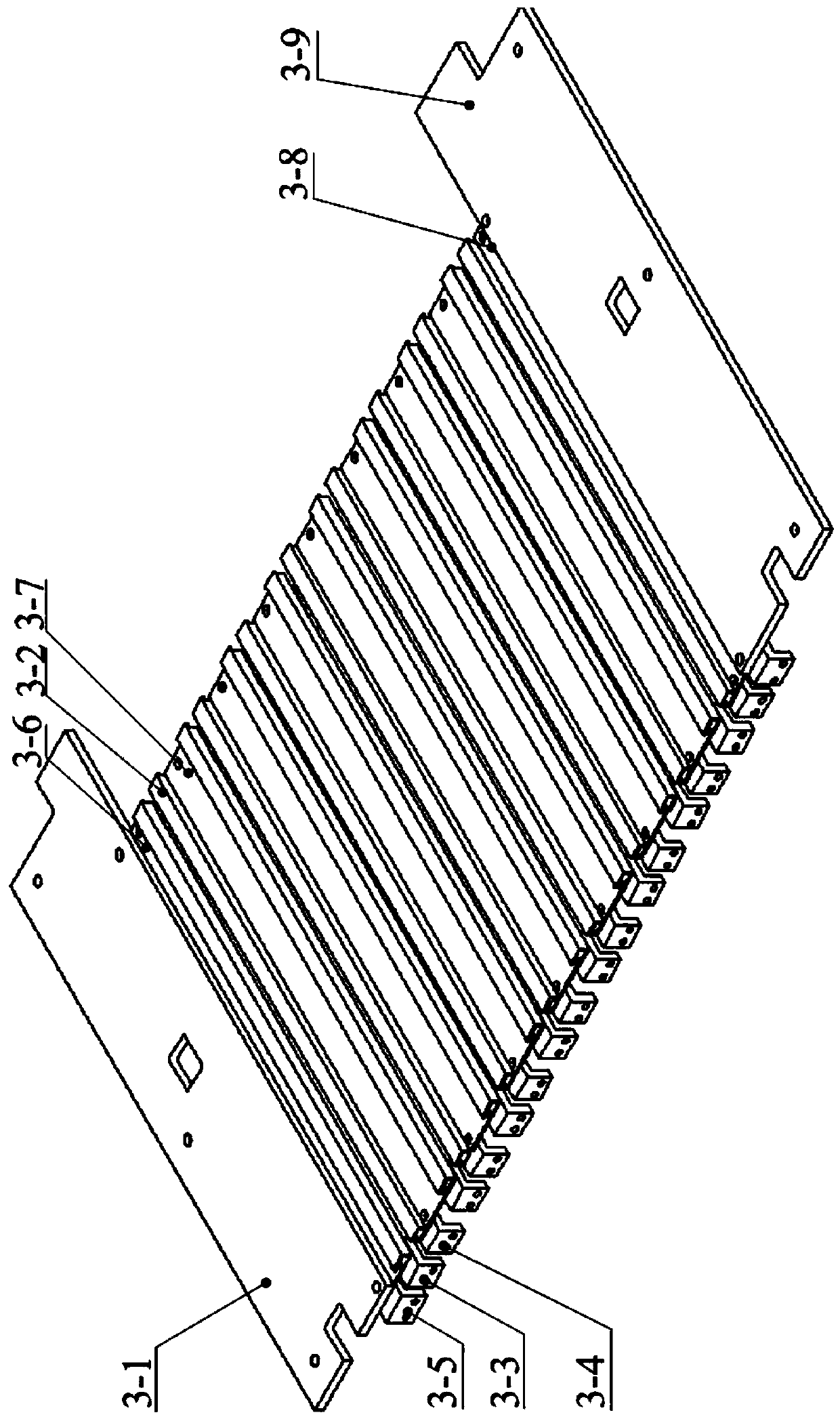

[0027] An automatic caching mechanism whose structure is as follows figure 1 As shown, it includes a longitudinal pushing lifting mechanism 1, a longitudinal guide rail 2 and a panel assembly 3.

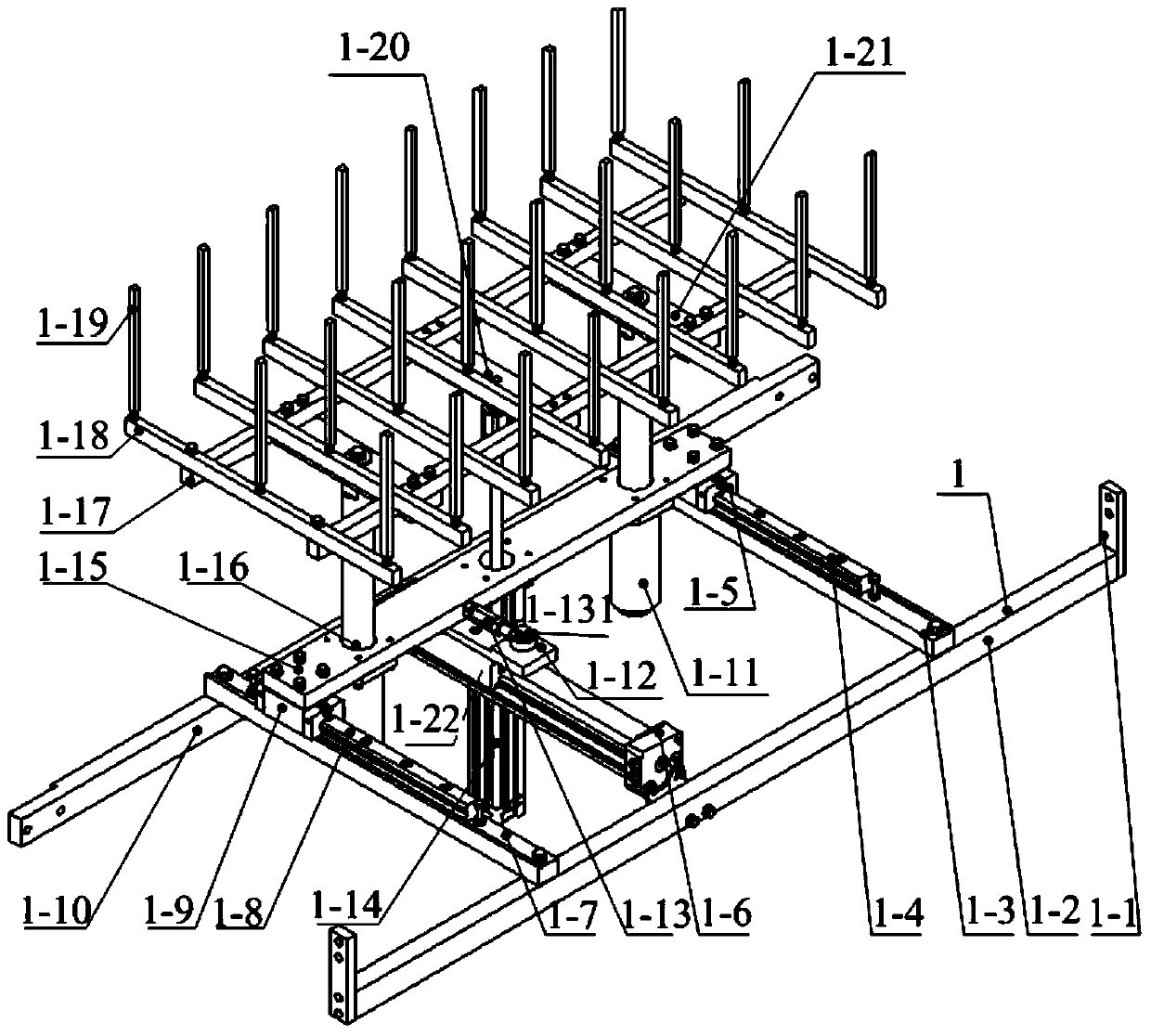

[0028] The structure of longitudinally pushing lifting mechanism 1 is as follows: figure 1 , 2 As shown, it includes two beams arranged in parallel at intervals, that is, the first beam 1-2 and the second beam 1-10, and the two ends of the first beam 1-2 are respectively vertically equipped with a beam connecting plate 1-1 through screws, It is used to fix the entire vertical push lifting mechanism 1 to the frame;

[0029] Between the first crossbeam 1-2 and the second crossbeam 1-10, a first longitudinal thrust guide rail backing plate 1-3, a longitudinal thrust cylinder 1-6 and a second longitudinal thrust guide rail backing plate 1-7 are arranged at inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com