Combined polyether for high flame-retardant water heater water tank and its preparation method and application

A flame retardant water heater combined with polyether technology, which is applied in the field of polyurethane, can solve the problems of increased cells, etc., and achieve the effects of improving fluidity, improving flame retardant performance, and increasing crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

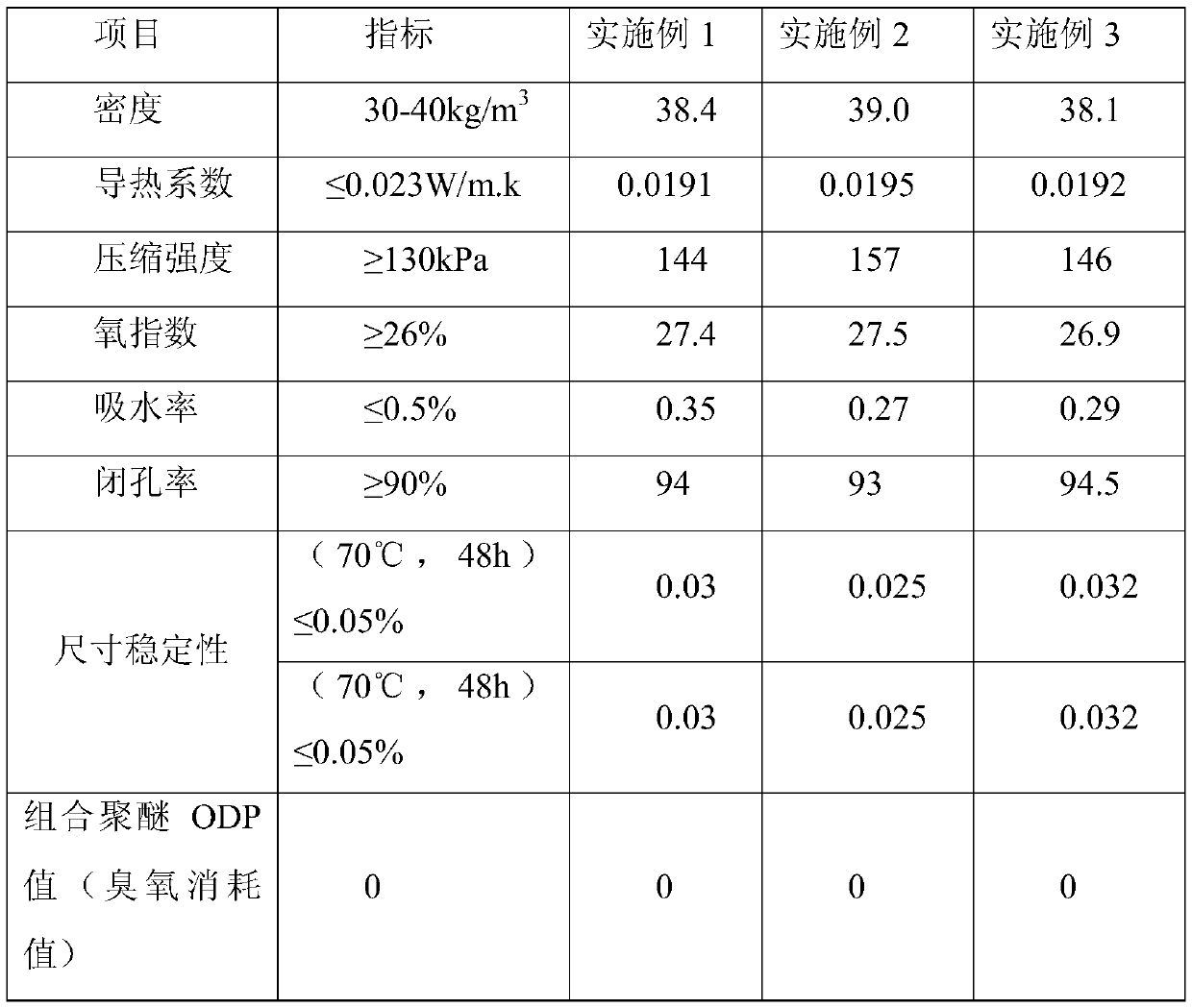

Examples

Embodiment 1

[0042] (1) Prepare component A, 200kg, weigh polyether polyol A: YNW-7001 (Shandong Yinuowei New Material Co., Ltd.), 42kg, polyether polyol B: YNW-482 (Shandong Yinuowei New Material Co., Ltd.) Materials Co., Ltd.), 37kg, polyester polyol C: PS-7001 (Nanjing Jinling Stepan Chemical Co., Ltd.), 27kg, foam stabilizer: Y-16268 (Maitive High-tech Materials Co., Ltd.), 2.2kg, chemical hair Foaming agent: deionized water, 2.3kg, catalyst: PC5, 0.5kg, PC8, 1.3kg, Y-27, 1.5kg, PC41, 0.6kg, PC46, 0.6kg, flame retardant: TCPP, 21kg, TEP 21kg, Physical blowing agent: a mixture of HFC-365mfc and HFC-245fa in a mass ratio of 95:5, a total of 43kg.

[0043] Add the weighed polyether polyol A, polyether polyol B, polyester polyol C, foam stabilizer, chemical foaming agent, catalyst, flame retardant and physical foaming agent into the reaction kettle in sequence, Stir at room temperature for 0.5 hour and mix thoroughly.

[0044] (2) B component diphenylmethane diisocyanate, 240kg.

[0045...

Embodiment 2

[0047] (1) Prepare component A, 200kg, weigh polyether polyol A: YNW-7001 (Shandong Yinuowei New Material Co., Ltd.), 36kg, polyether polyol B: YNW-482 (Shandong Yinuowei New Material Co., Ltd.) Material Co., Ltd.), 41kg, polyester polyol C: PS-7001 (Nanjing Jinling Stepan Chemical Co., Ltd.), 25kg, foam stabilizer: Y-16268 (Maitive High-tech Materials Co., Ltd.), 2.5kg, chemical hair Foaming agent: deionized water, 2.4kg, catalyst: PC5, 0.6kg, PC8, 1.4kg, Y-27, 1.6kg, PC41, 0.4kg, PC46, 1.1kg, flame retardant: TCPP, 23kg, TEP 23kg, Physical foaming agent: a mixture of HFC-365mfc and HFC-245fa at a mass ratio of 95:5, a total of 42kg.

[0048]Add the weighed polyether polyol A, polyether polyol B, polyester polyol C, foam stabilizer, chemical foaming agent, catalyst, flame retardant and physical foaming agent into the reaction kettle in sequence, Stir at room temperature for 0.5 hour and mix thoroughly.

[0049] (2) B component diphenylmethane diisocyanate, 260kg.

[0050] ...

Embodiment 3

[0052] (1) Prepare component A, 200kg, weigh polyether polyol A: YNW-7001 (Shandong Yinuowei New Material Co., Ltd.) 41kg, polyether polyol B: YNW-482 (Shandong Yinuowei New Material Co., Ltd.) Co., Ltd.), 41kg, polyester polyol C: PS-7001 (Nanjing Jinling Stepan Chemical Co., Ltd.), 20kg, foam stabilizer: Y-16268 (Momentive High-tech Materials Co., Ltd.), 2.8kg, chemical foaming Agent: deionized water, 2.4kg, catalyst: PC5, 0.5kg, PC8, 1.2kg, Y-27, 1.5kg, PC41, 0.5kg, PC46, 1.1kg, flame retardant: TCPP, 21.5kg, TEP 21.5kg , Physical foaming agent: HFC-365mfc and HFC-245fa according to the mass ratio of 95:5 mixture of a total of 45kg.

[0053] Add the weighed polyether polyol A, polyether polyol B, polyester polyol C, foam stabilizer, chemical foaming agent, catalyst, flame retardant and physical foaming agent into the reaction kettle in sequence, Stir at room temperature for 0.5 hour and mix thoroughly.

[0054] (2) B component polymethylene polyphenylisocyanate, 250kg.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com