Brushless disc double rotor motor

A dual-rotor motor and brushless disc technology, applied in motors, electric components, electric vehicles, etc., can solve the problems of inconvenient maintenance and replacement of intermediate phase windings, inconvenient manufacture or maintenance of outer rotor windings, low efficiency and reliability, etc. , to achieve the effect of light weight, compact structure and compact internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

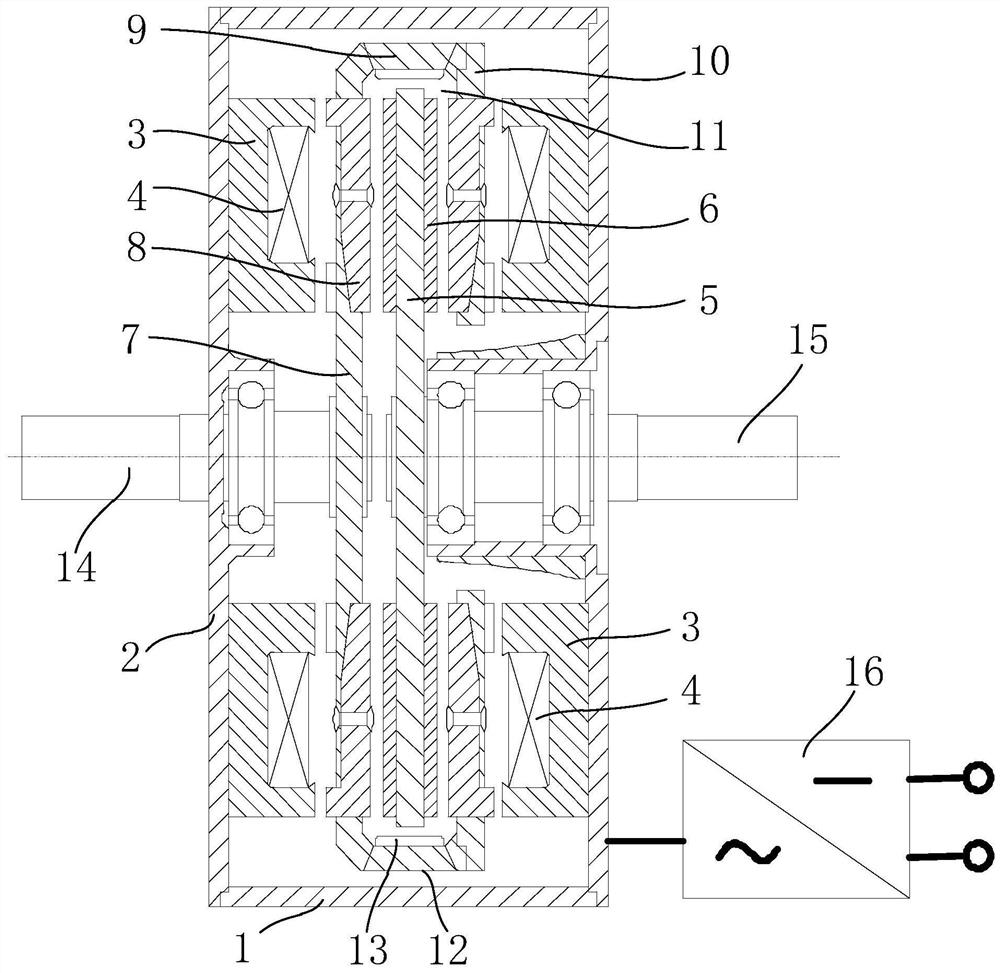

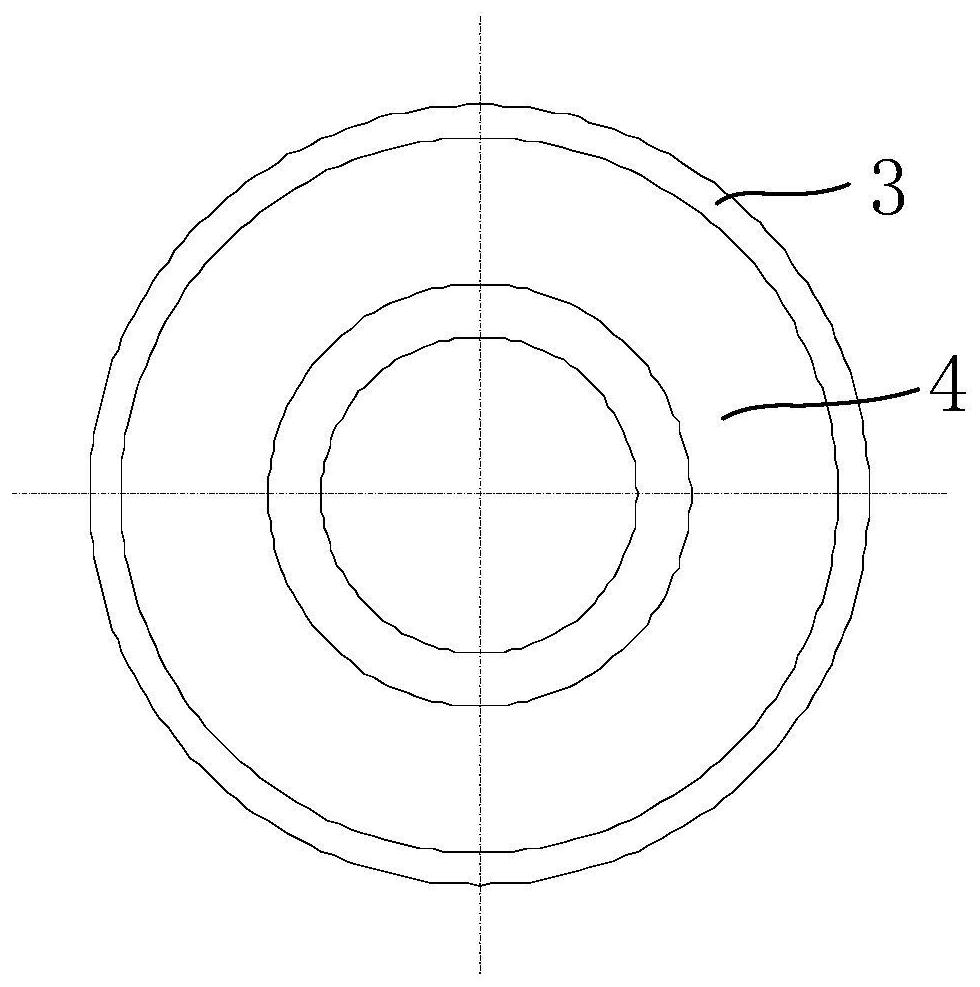

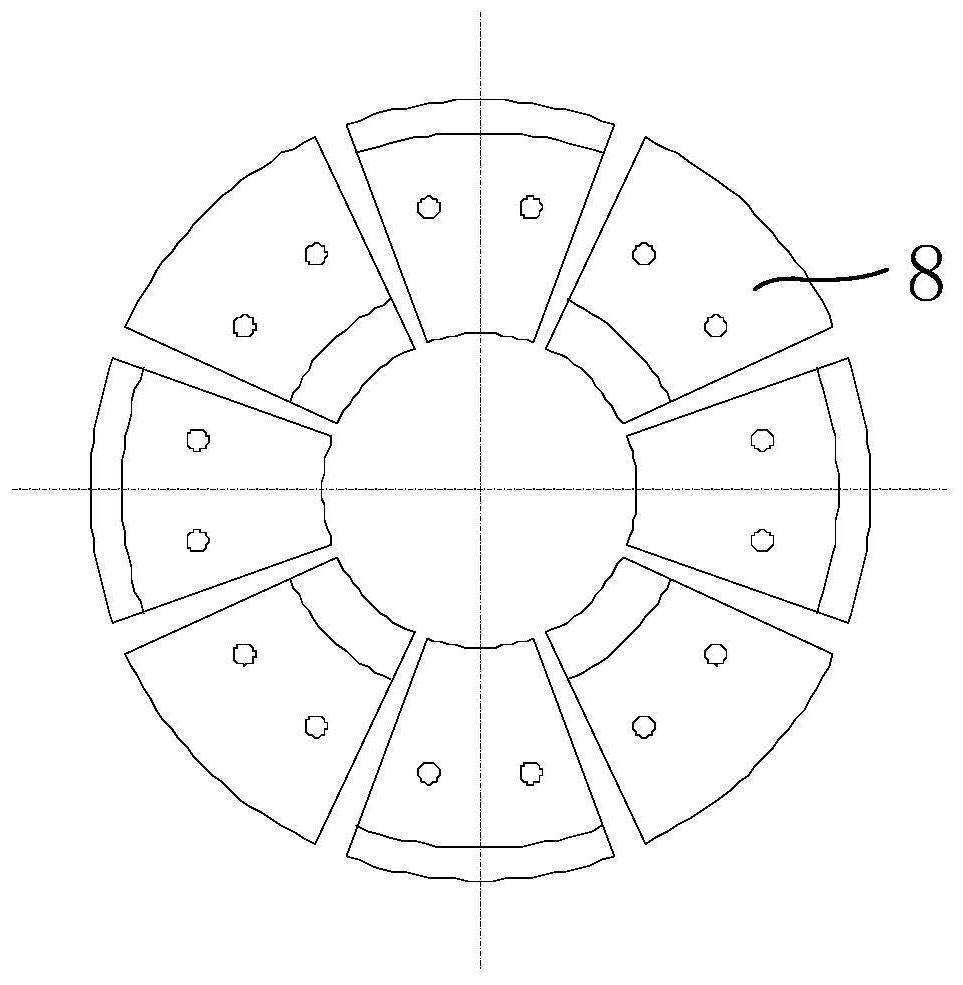

[0034] Such as Figure 1 to Figure 4 As shown, the brushless disc-type double-rotor motor includes motor housing, stator, inner rotor, inner rotor output shaft 15, outer rotor, outer rotor output shaft 14, inverter 16 and other components, wherein the inverter is preferably Two-phase inverter, the specific structure of each component is as follows:

[0035] The motor casing is mainly used to accommodate and protect various components, specifically including the casing 1 and the end cover 2 . Among them, the shell is cylindrical, and the two end caps are respectively fixed at its two ends to form a space for accommodating various components, and maintain a certain gap with the internal components. There is a through hole in the center of the end cap, and the through hole Equipped with one-piece shaft sleeve, the output shaft of the inner rotor and the output shaft of the outer rotor are respectively placed in the through holes of the two end covers and the shaft sleeve through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com