Shallow carbon monoxide conversion method and system

A carbon monoxide and shallow technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as hidden dangers in system operation, difficult operation, and large system resistance, so as to reduce invalid materials and prevent dew point corrosion , The effect of outlet temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

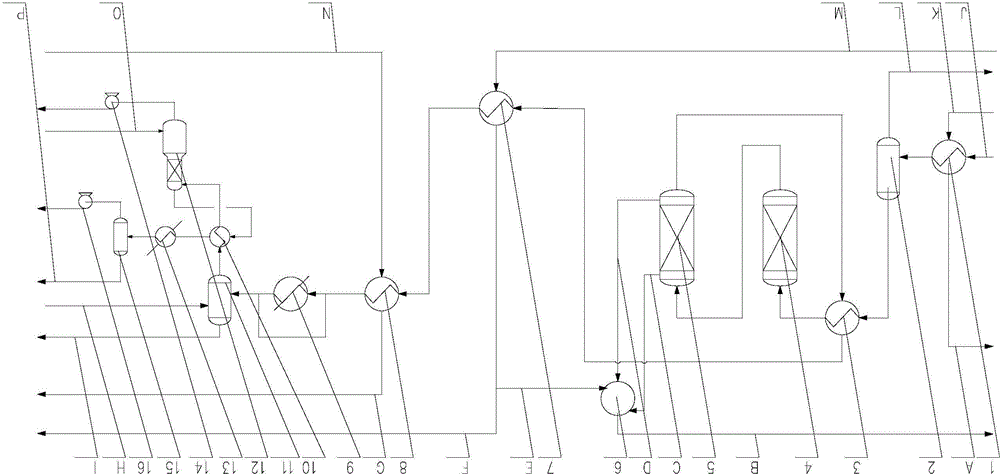

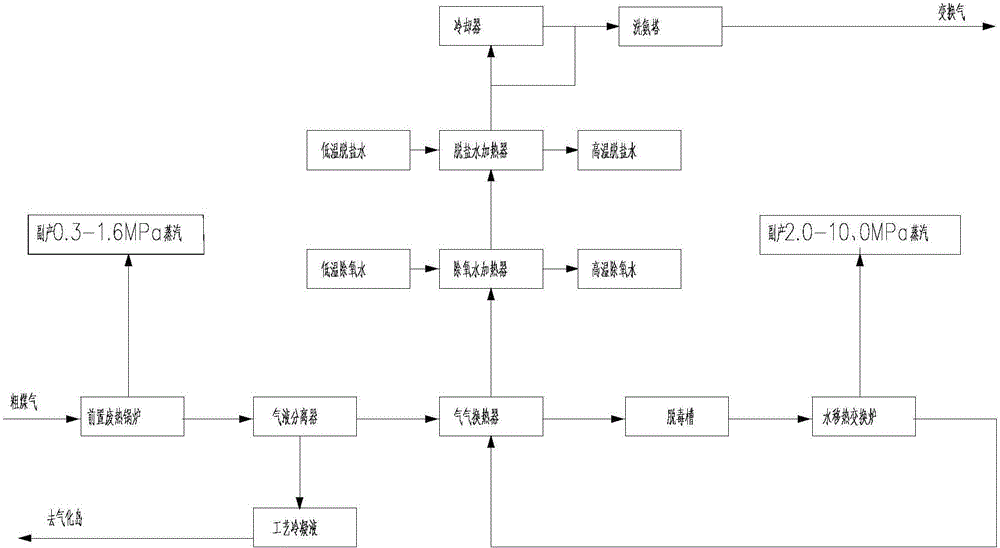

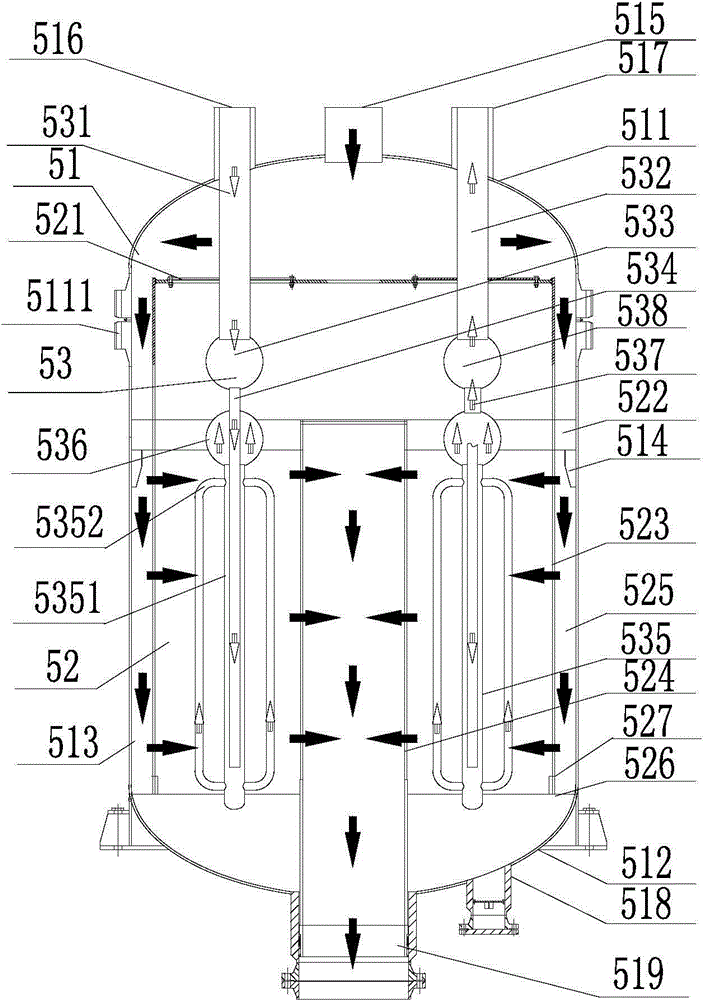

[0037] Such as figure 1 and figure 2 As shown, a system for shallow conversion of carbon monoxide includes two circuits, one of which includes a pre-connected waste heat boiler 1, a gas-liquid separator 2, a gas-gas heat exchanger 3, a deoxygenated water heater 7, and a desalinated water heater. Heater 8, cooler 9 and ammonia washing tower 11 also include detoxification tank 4 and water transfer heat conversion furnace 5, gas-gas heat exchanger 3, detoxification tank 4 and water transfer heat conversion furnace 5 are connected in sequence, water transfer The gas flow outlet of the heat conversion furnace 5 is returned to the gas-gas heat exchanger 3; the other path includes a mixing heater 10, a flash tower 12, a water cooler 13 and a flash gas separator 15, an ammonia washing tower 11, a mixing heater 10 and a flash gas separator. The steam towers 12 are connected in sequence, the air outlet of the flash tower 12 returns to the hybrid heater 10, and the other outlet of the ...

Embodiment 2

[0067] This embodiment is a 900,000-ton methanol / year conversion device designed by a chemical group for pressurized gasification of coal-water slurry. Other implementation methods are the same as in Embodiment 1. The specific indicators are shown in Table 2. It can be seen from the table that the investment estimate is at least halved.

[0068] Table 2 Comparison list of main process indicators between the process of Example 2 and the traditional adiabatic shift process

[0069]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap