Container room and combined container room

A container house and container technology, which is applied in the direction of construction and building construction, can solve the problems of small space, time-consuming and laborious disassembly and assembly, and achieve the effects of saving manpower, expanding the landing area, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

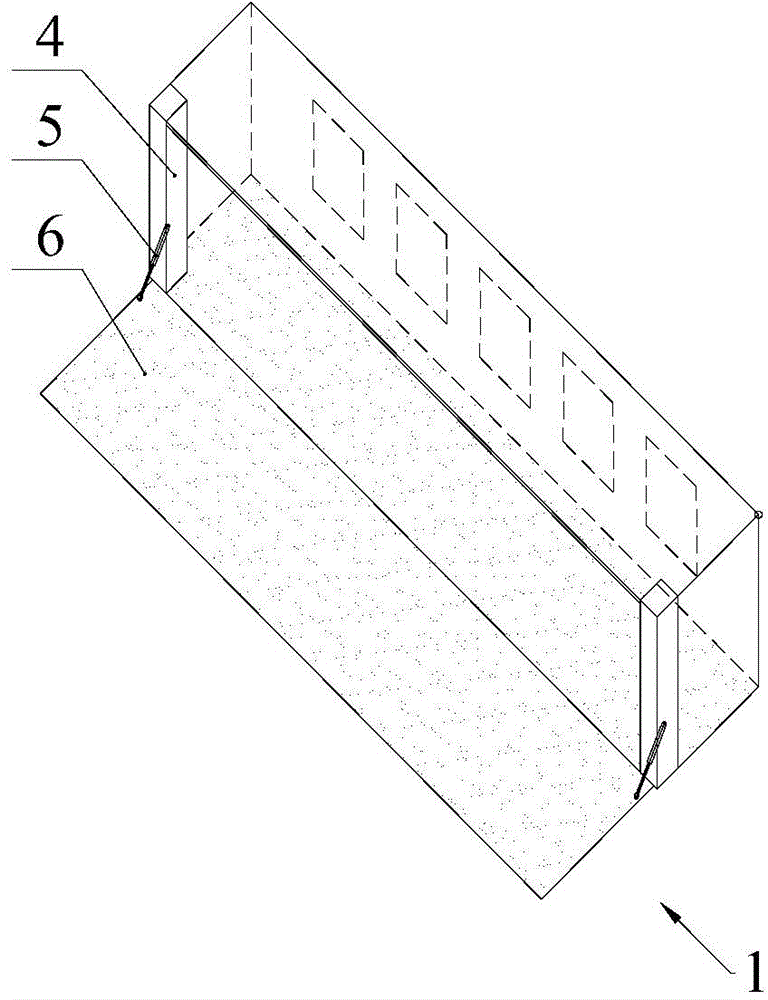

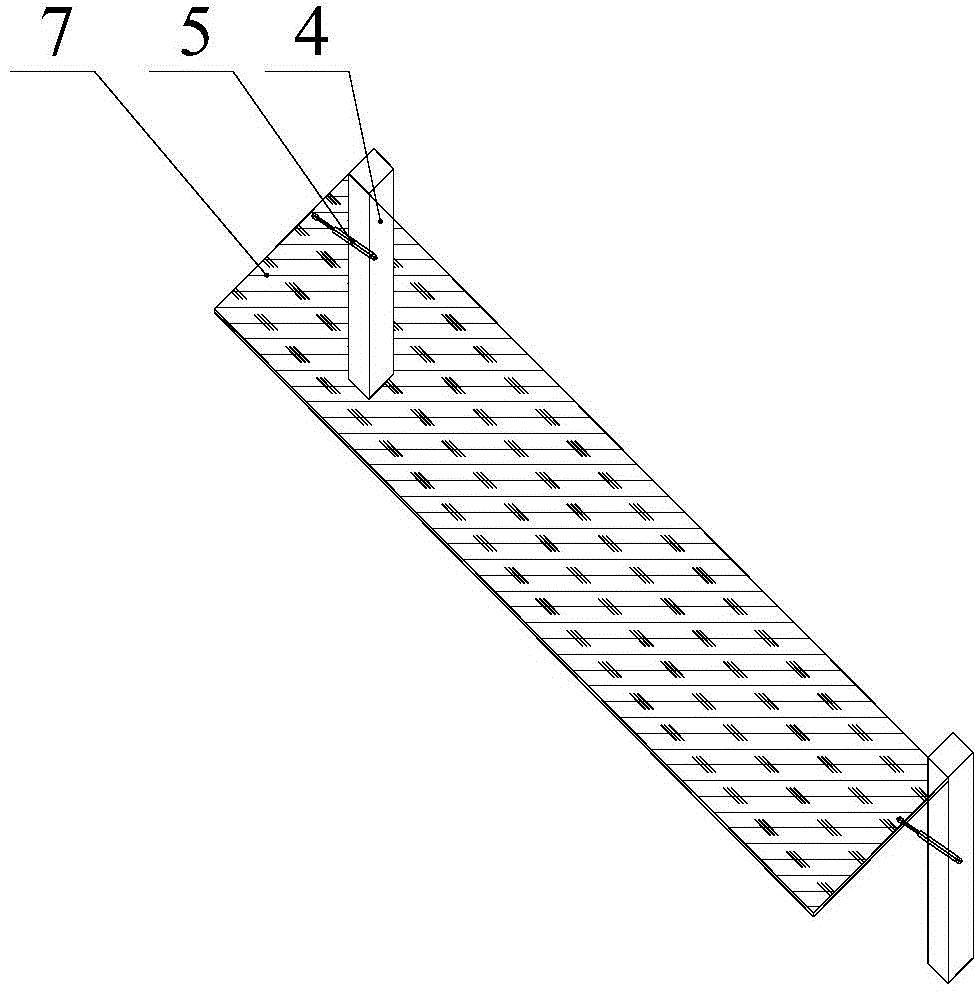

[0047] Such as Figure 1~2 As shown, a container house includes a first container body 1, and the first container body includes a bottom plate, a top plate, two opposite long side plates and two opposite short side plates, among the two long side plates , one of the long side panels is a movable side panel 6, the movable side panel 6 is hingedly matched with the bottom plate of the first container body, and the inner side of the movable side panel 6 in the first container body is provided with a first shielding panel 7 that can expand outwards, The first shielding plate 7 is hingedly fitted with the top plate of the first container body.

[0048] The first container body 1 is provided with a plurality of first hydraulic cylinders 5 for respectively pushing the movable side plate 6 to rotate downward and the first shielding plate 7 to rotate upward.

[0049] In order to ensure the requirements of force and strength, a load-bearing column 4 is arranged in the first container bo...

Embodiment 2

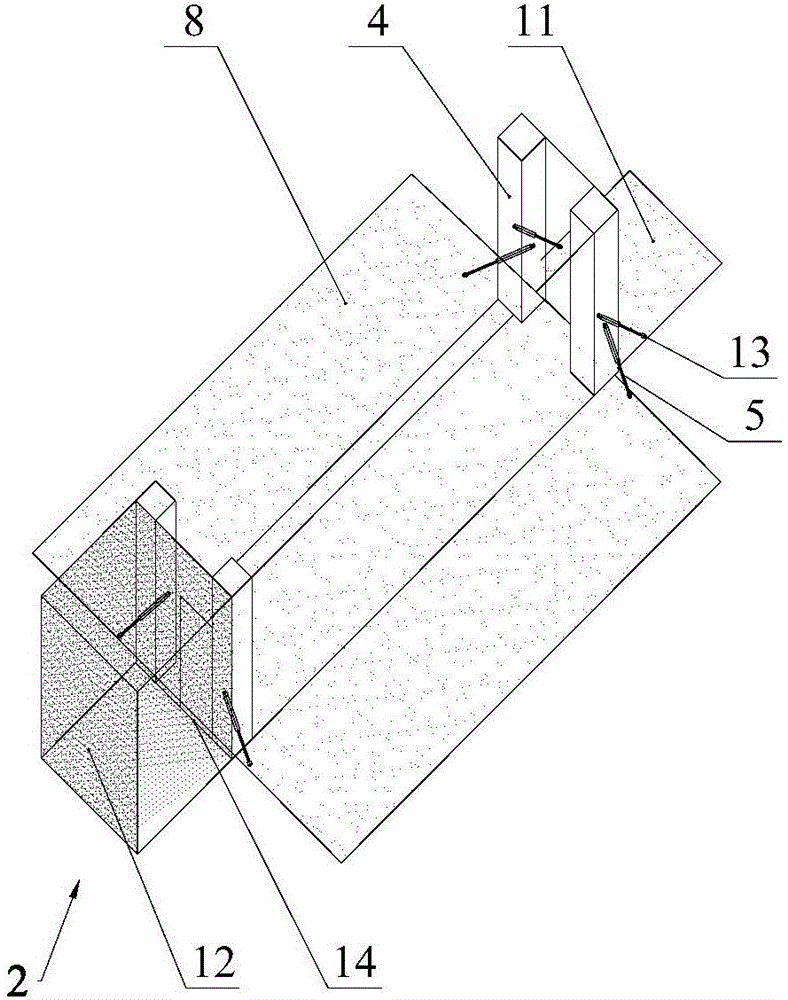

[0054] Such as image 3 and 4 As shown, a container house includes a second container body 2, the second container body includes a bottom plate, a top plate, two opposite long side plates and two opposite short side plates,

[0055] The two short side plates of the second container body are respectively the first short side plate 11 and the second short side plate 12, wherein the first short side plate 11 is hingedly fitted with the bottom plate of the second container body 2, and the second short side plate The upper and lower ends of 12 are respectively fixed with the bottom plate and the top plate of the second container body;

[0056] Both long side panels of the second container body include:

[0057] The movable part 8, the bottom end is hingedly matched with the bottom plate of the second container body 2;

[0058] The fixed part 14 is adjacent to or against the movable part 8, and the fixed part 14 is respectively fixed to the bottom plate, the top plate and the sec...

Embodiment 3

[0065] Such as figure 1 , 2 , 5, 6, 7, 8, and 9, a combined container house includes a first container body 1 and a second container body 2, such as figure 1 and 2 As shown, the first container body and the second container body both include a bottom plate, a top plate, two opposite long side plates and two opposite short side plates, and one long side plate of the first container body 1 is movable Side plate 6, the movable side plate 6 is hingedly matched with the bottom plate of the first container body, and the inner side of the movable side plate in the first container body is provided with a first shielding plate 7 hinged with the top plate of the first container body;

[0066] Such as Figure 4 and 5 As shown, the two short side panels of the second container body 2 are respectively the first short side panel 11 and the second short side panel 12, wherein the first short side panel 11 is hingedly fitted with the bottom plate of the second container body, and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com