Large-span net rack aloft pairing, installing and overall horizontal moving method

A large-span, network frame technology, which is applied in the field of handling or processing, preparation of building materials or building components on site, transportation or assembly of building components, can solve problems such as the impact of equipment installation time limit, and achieve the goal of overcoming the limitation of site conditions and ensuring safety Good controllability and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

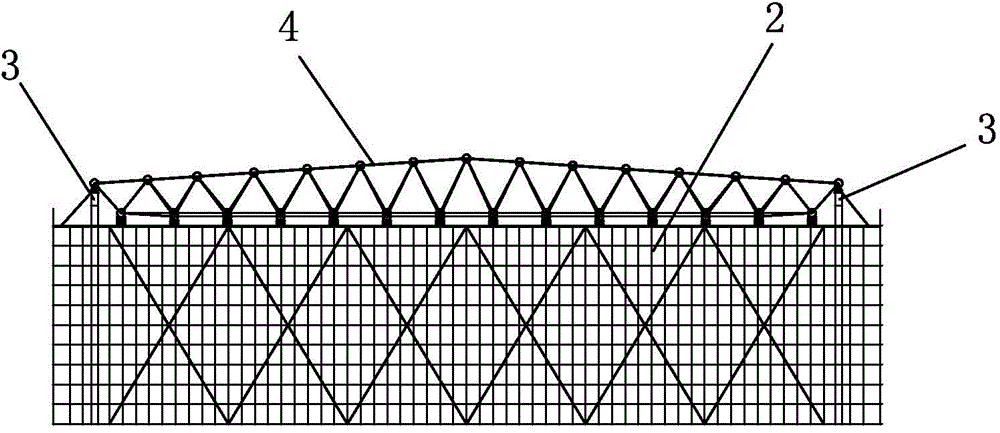

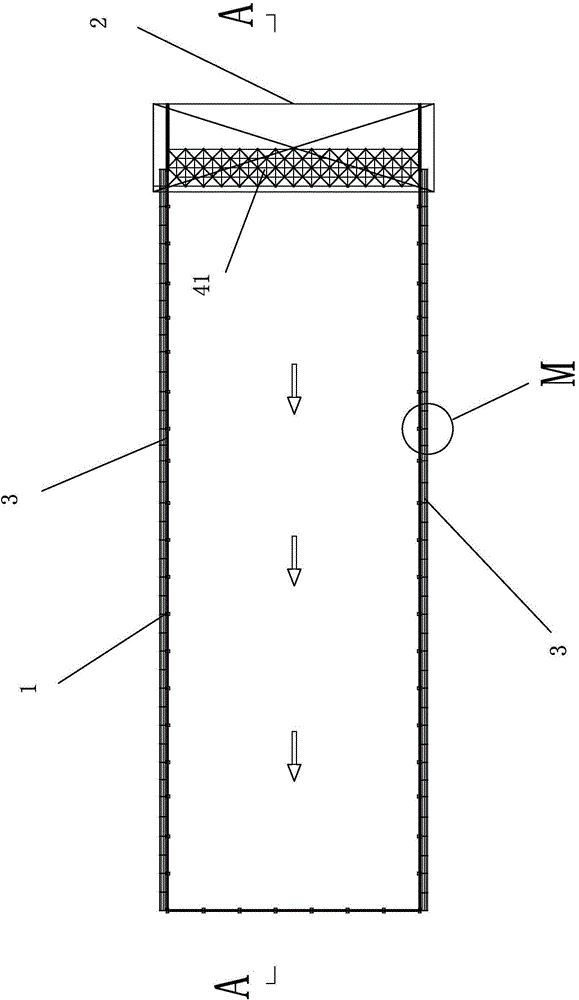

[0046] like Figure 1 to Figure 10 As shown, the network frame in the present invention is a quadrangular pyramidal network frame 4 placed upright, and a method for overall translation of large-span network frame high-altitude group pair installation in the present invention includes the following steps:

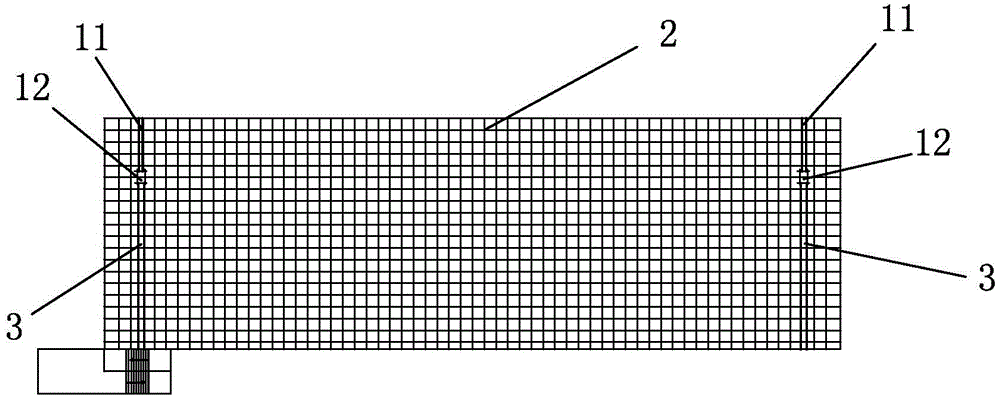

[0047] (1) set up a scaffolding operating platform 2 at the right end of the frame 1 along the length direction of the plant frame 1, and this platform 2 can also be set up at the left end of the frame 1, as long as it is set up at one end of the plant;

[0048] (2) Two mutually parallel sliding rails 3 are arranged above the scaffolding platform 2, and the sliding rails 3 extend along the length direction of the frame 1, and are erected on the steel beam 11 or steel column 12 of the frame 1 Above, the square pyramid grid 4 is a common grid structure, and the specific layout method of steel beams 11 or steel columns 12 refers to conventional technical means;

[0049] (3) comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com