Combined bottle cap for installation of decorative part and manufacturing method thereof

A manufacturing method and technology for decorative parts, applied in the directions of packaging, transportation and packaging, closing, etc., can solve problems such as low efficiency and single method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

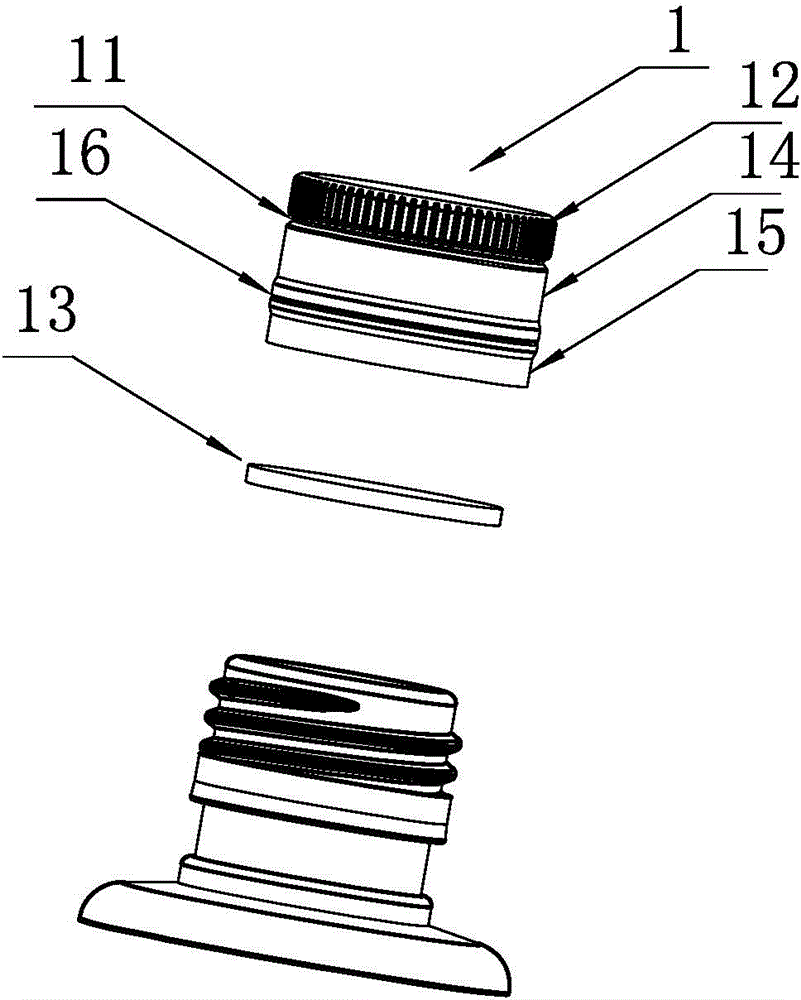

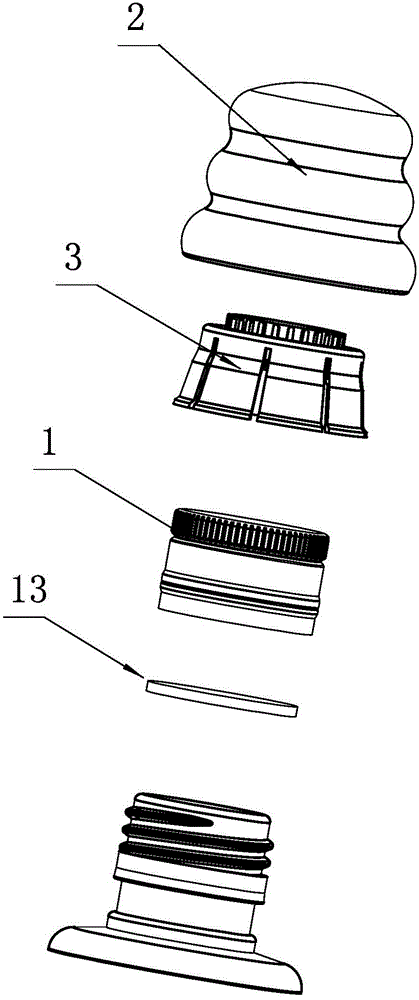

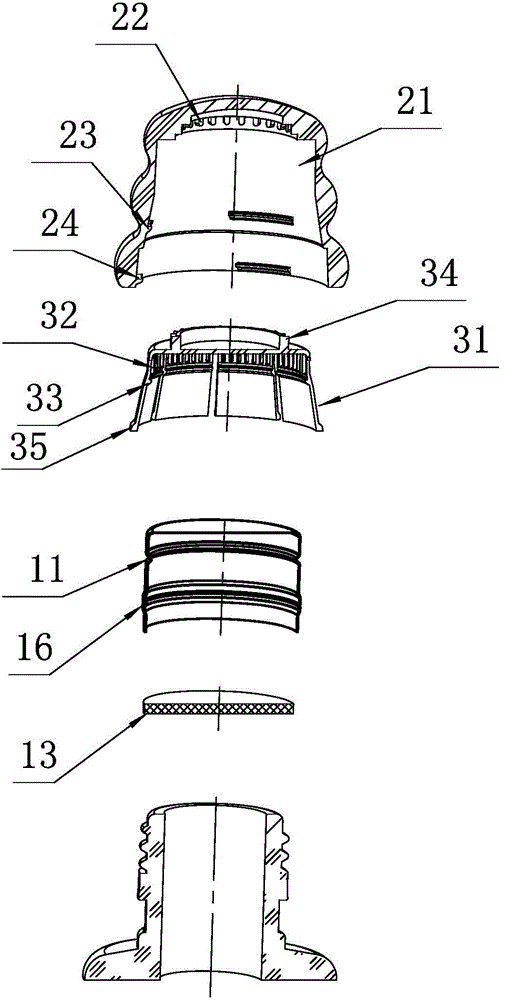

[0027] Such as figure 1 with 2 As shown, the combined bottle cap for installing decorative parts of the present embodiment is based on the existing bottle cap, and an outer cover 2 and a bushing 3 with decorative parts are added. The above-mentioned existing bottle cap is a A specific bottle cap (see figure 1 ), specifically, including a cover body 1, the cover body 1 is divided into an upper part 14 and a lower part 15 and connected as a whole through a connection point 16, and the upper part 14 of the cover body 1 also has an annular indentation groove 11 and anti-slip teeth 12 , The indentation groove 11 is located under the anti-skid tooth 12 .

[0028] Such as Figure 2-4 As shown, the cover body 1 can be fixed in the bushing 3. Specifically, the bushing 3 is a cylindrical sleeve, and the upper side of the inner tube of the cylindrical sleeve is provided with a lower stop gear 32, which is connected with the cover body 1. The anti-slip teeth 12 cooperate with each oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com