Method for cutting sponge-liked sound-absorbing material for wall by hydraulic press

A sound-absorbing material, hydraulic press technology, applied in electrical program control, metal processing, etc., can solve problems such as roughness, low efficiency, and inability to adapt to large-scale mechanized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

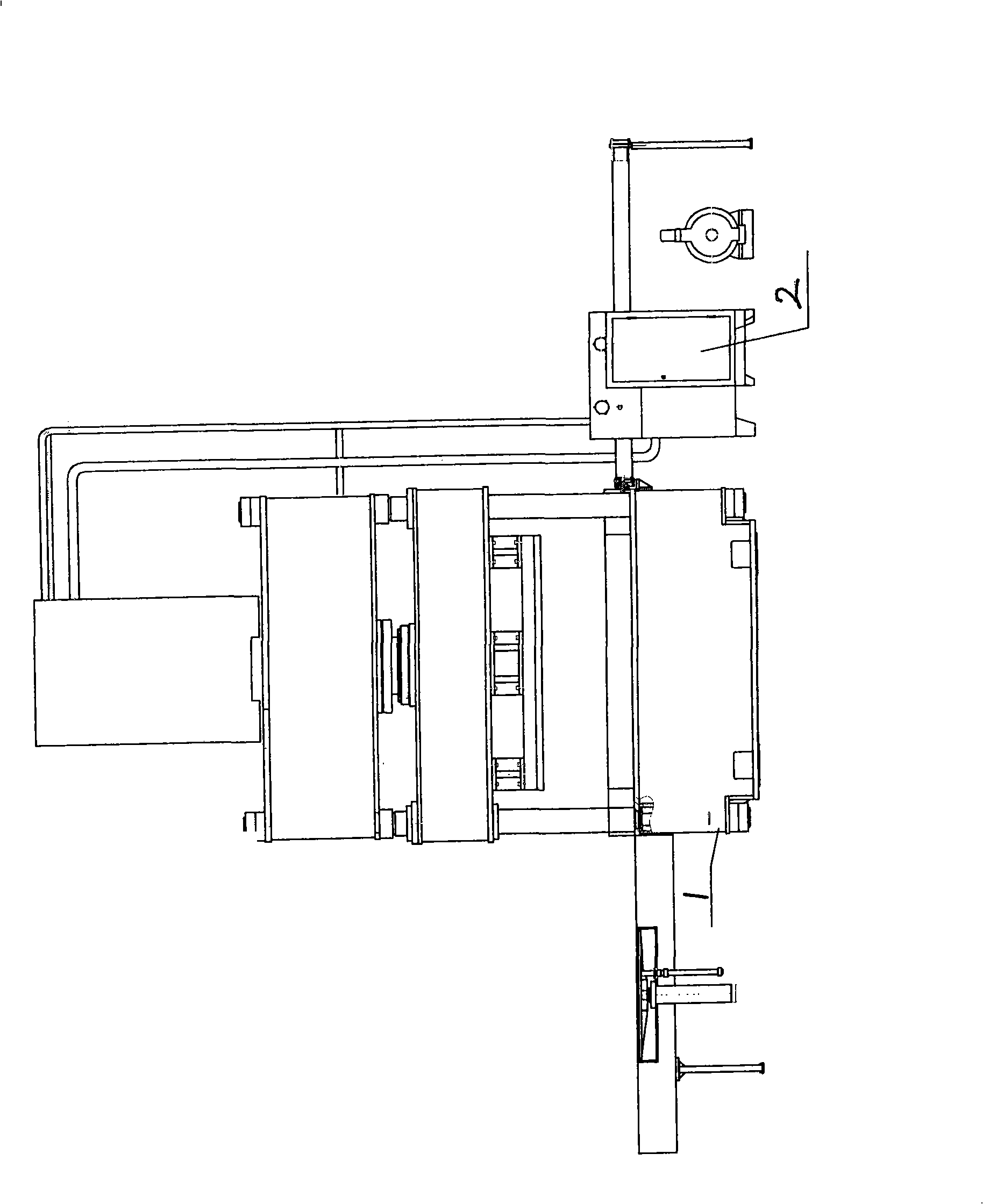

[0008] Implementation method: the processing method of the spongy wall sound-absorbing material workpiece as shown in the figure, firstly design the relevant workpiece to be processed, and input the design into the computer, and then design the stroke, differential and punching of the hydraulic press according to the needs Finally, place the workpiece on the workbench 1 of the hydraulic press, turn on the corresponding button on the electrical cabinet 2, and the cutting program of the hydraulic press can automatically cut and process to obtain the required workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com