Coal mine drilling and dust removal device

A dust removal device and coal mine technology, which is applied in construction and other fields, can solve the problems of coal dust and gas gas cannot be drained, gaps, triangular drill pipes cannot be sealed with a dust cover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

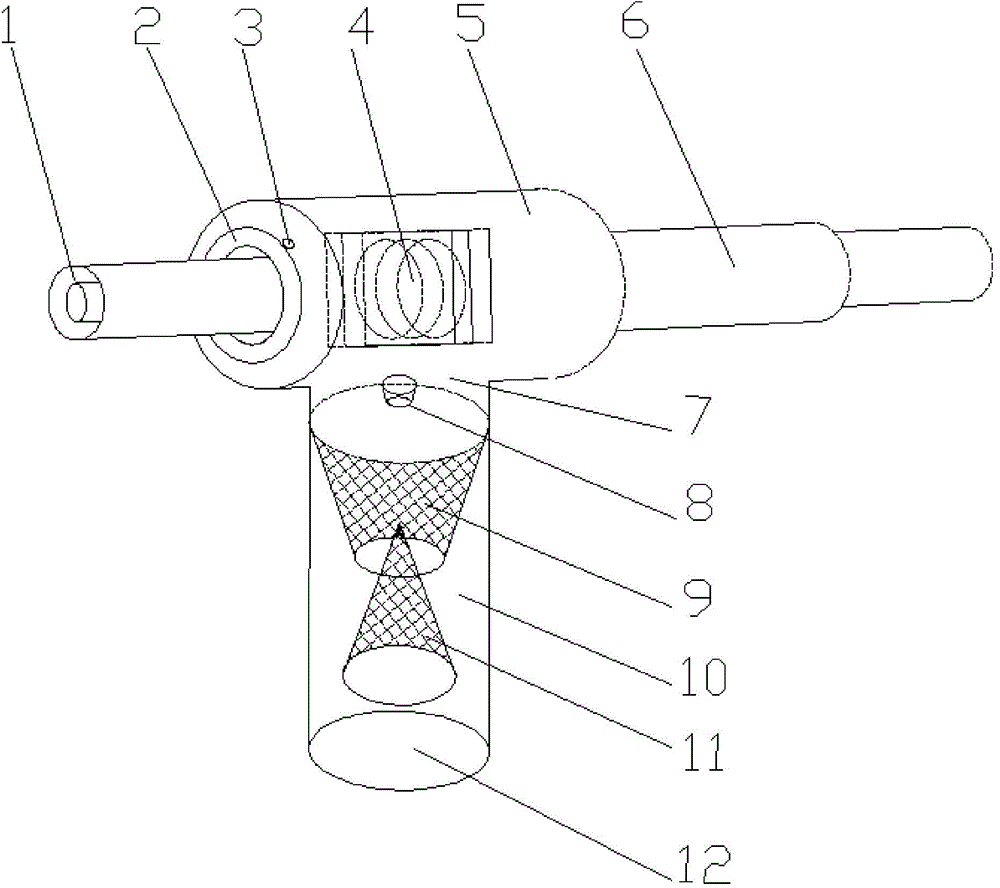

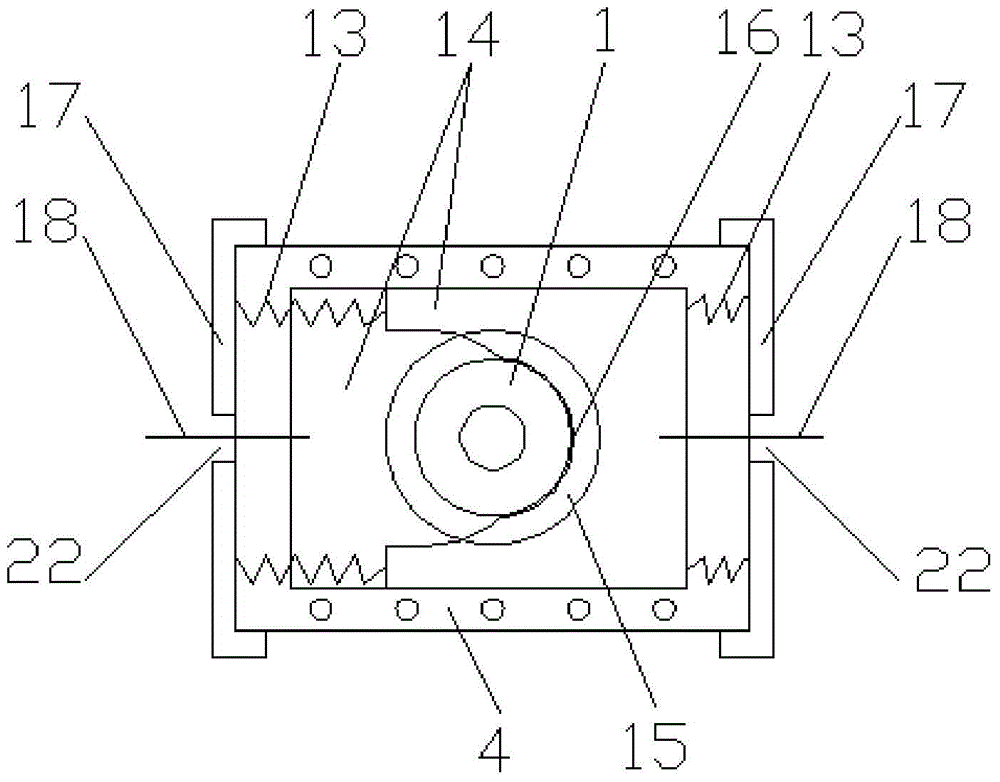

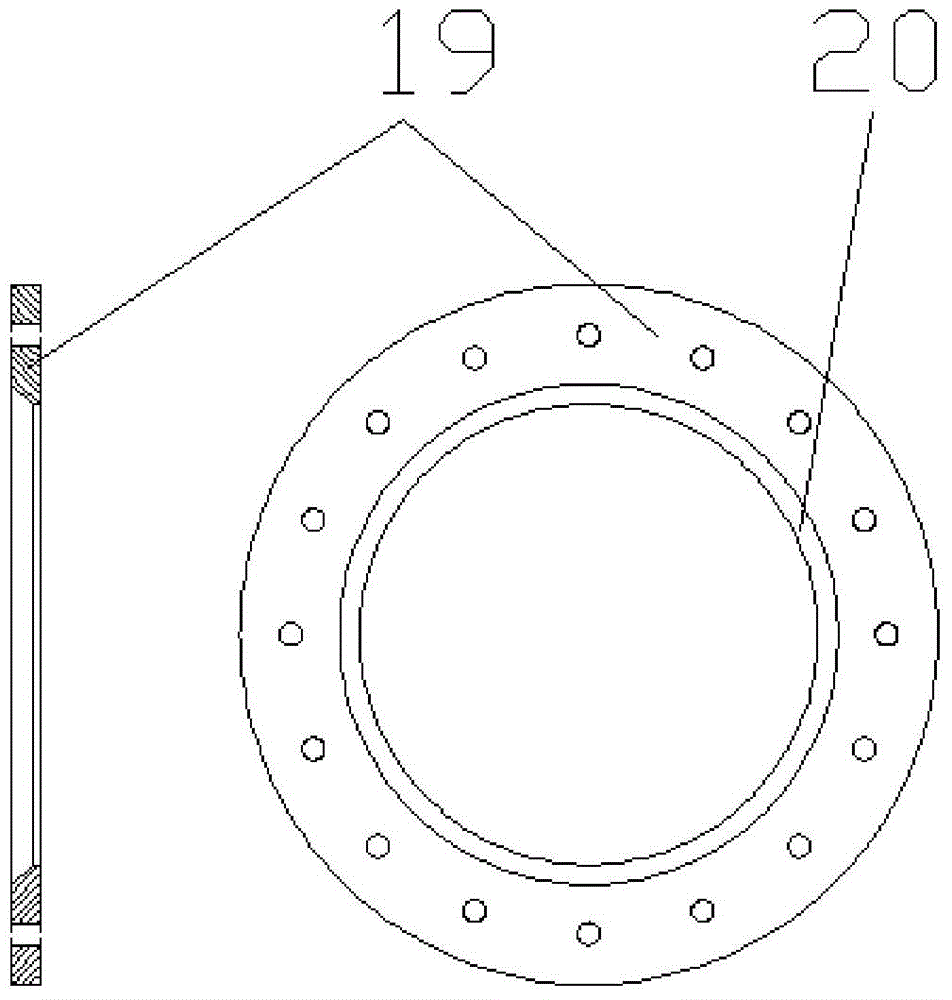

[0014] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a coal mine drilling dust removal device includes a drill pipe 1, and the outside of the drill pipe 1 is provided with a buried pipe 6, and the outside of the buried pipe 6 is provided with a dust collection cover 5, and the bottom of the dust collection cover 5 is provided with a The lower outlet 7, the center of the outer end of the dust collection cover 5 is provided with an annular air-pressing air knife 2; The upper plate 19 is provided with a bell mouth 20, and the upper plate 19 and the lower plate 21 are connected and fixed by bolts; the center of the dust collection cover 5 is provided with a splint 4; the left and right sides of the splint 4 Sides are respectively provided with baffles 14, the upper and lower sides of the splint 4 are fixedly connected to each other by bolts and form two baffle channels, the left and right ends of the splint 4 are welded to the dust collection cover 5 and are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com