Self-lubricating gear

A self-lubricating, gear technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, components with teeth, etc., can solve the problems of poor gear lubrication, reduce the service life of gears, etc., and achieve the effect of improving the lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

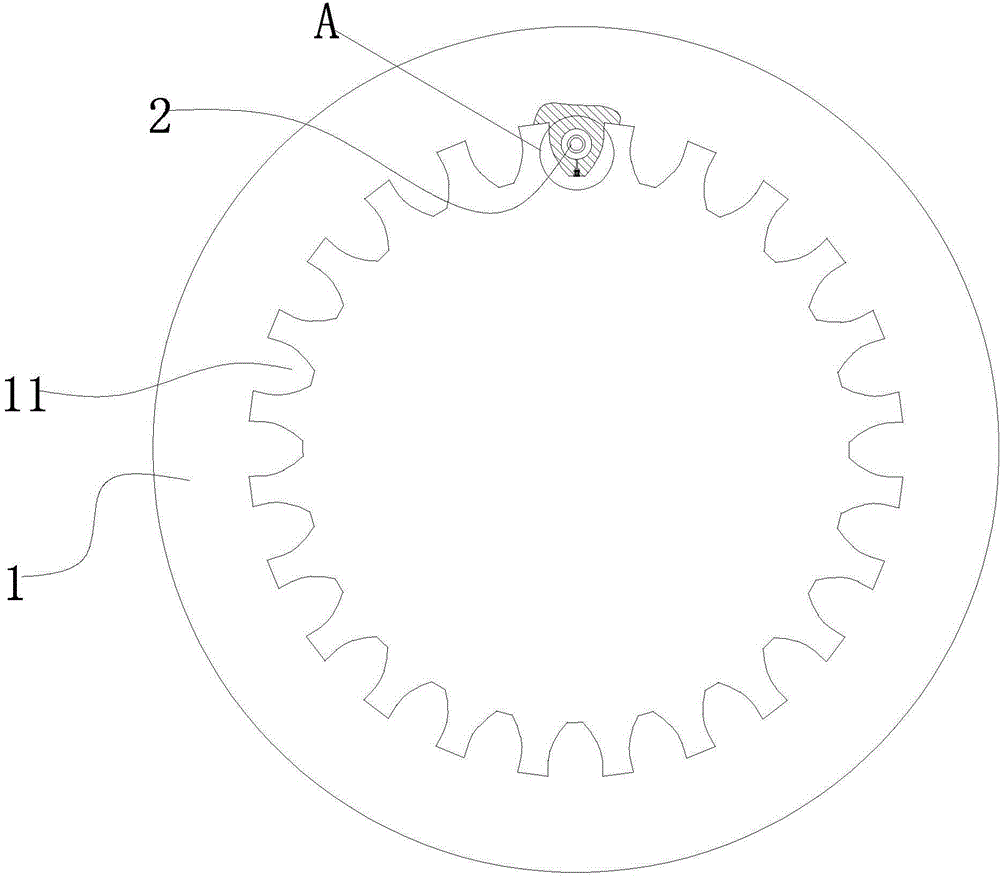

[0021] Such as figure 1 As shown, a self-lubricating gear, the gear 1 is an internal gear. There are six gear teeth 11 in the gear that are provided with self-lubricating device 2, and the six gear teeth that are provided with self-lubricating device are circumferentially evenly distributed.

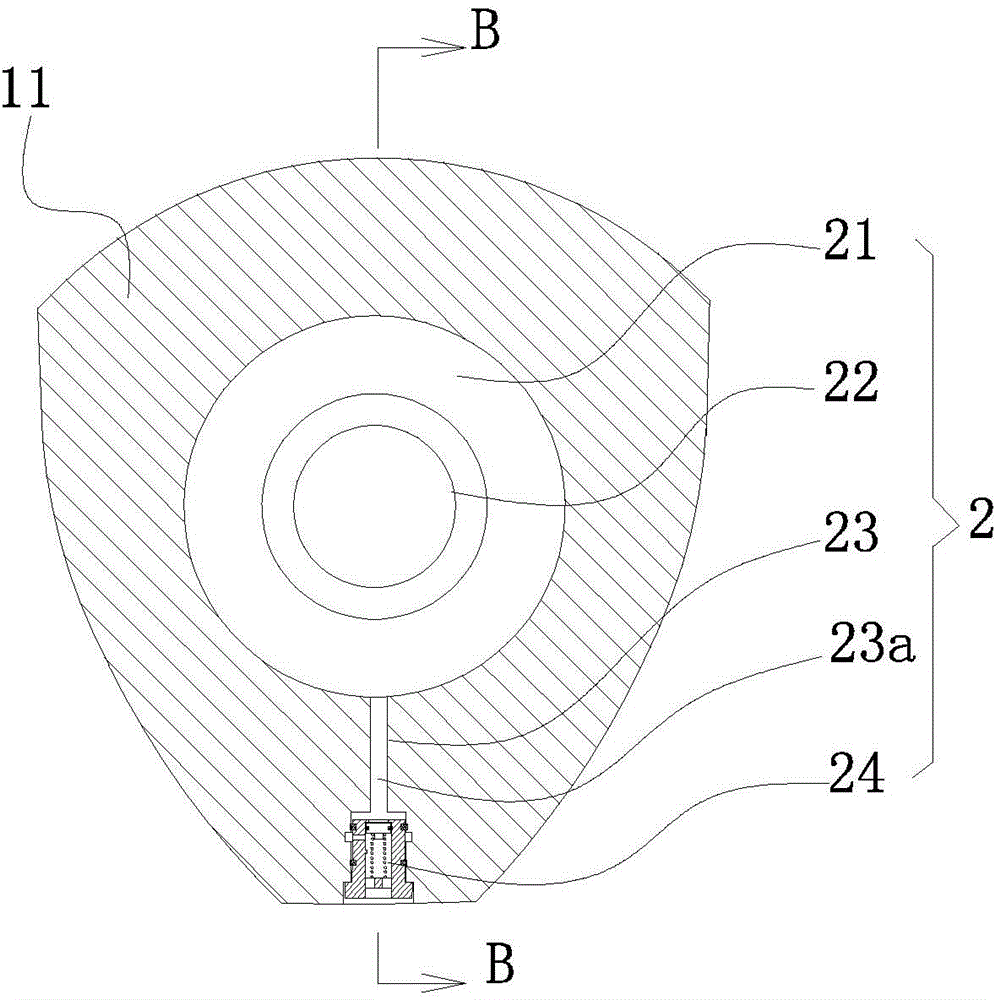

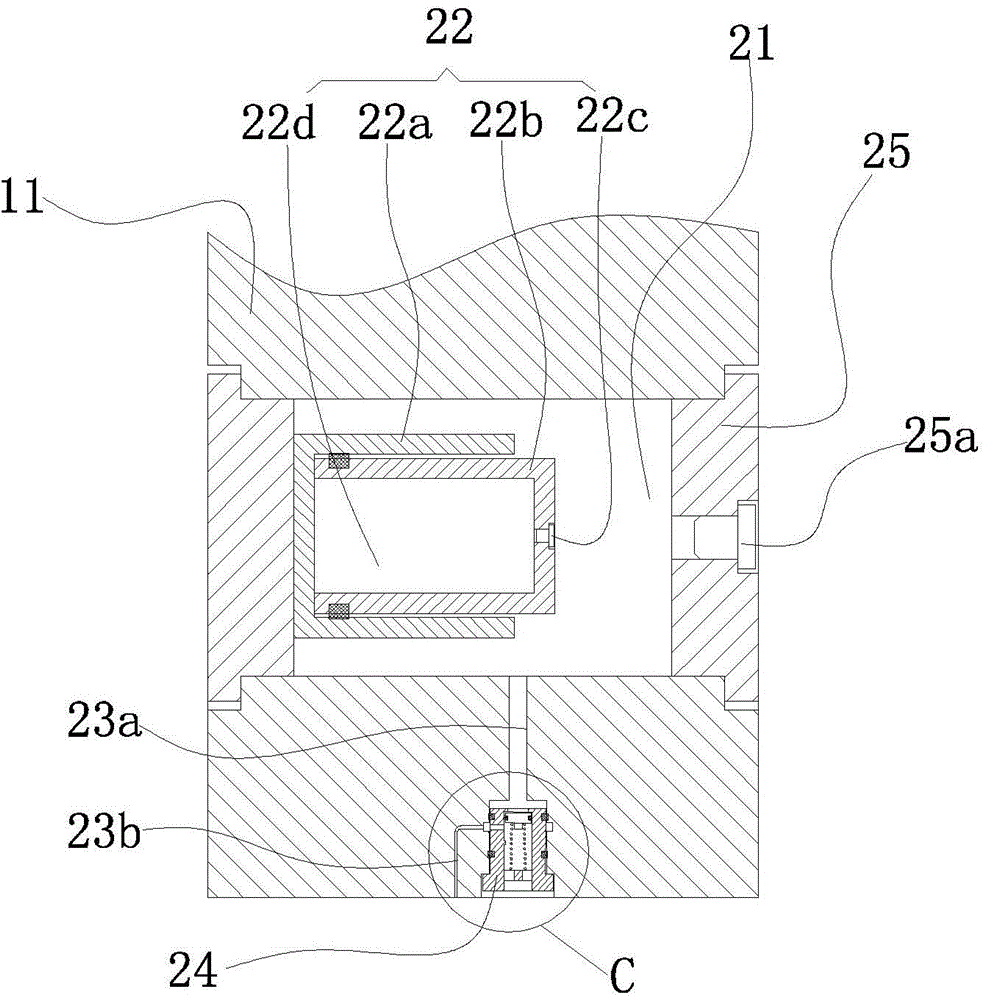

[0022] The self-lubricating device includes an oil storage chamber 21 arranged in the gear teeth, an adaptive telescopic device 22 arranged in the oil storage chamber, a lubricating oil passage 23 arranged in the gear teeth and an automatic opening and closing of the lubricating oil passage arranged in the gear teeth. Closing device 24. The oil storage chamber is a cylindrical cavity parallel to the axis of the gear. The oil storage chamber runs through both ends of the gear. The two ends of the oil storage chamber are respectively provided with sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com