Electric vehicle compound gear

A technology for compound gears and electric vehicles, which is applied in the directions of gear lubrication/cooling, belt/chain/gear, transmission parts, etc. It can solve problems such as poor gear lubrication and reduce the service life of gear shafts, so as to improve the lubrication effect and reduce the vibration, good intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

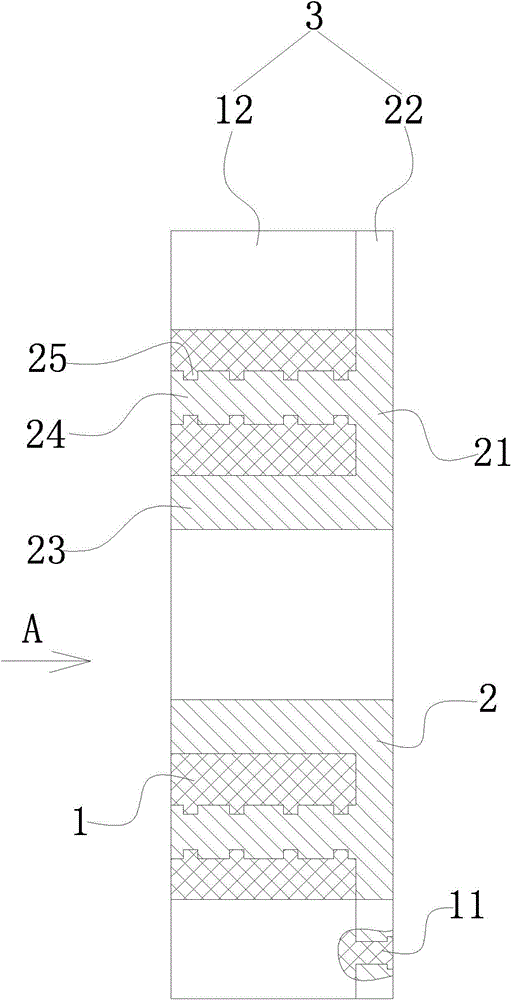

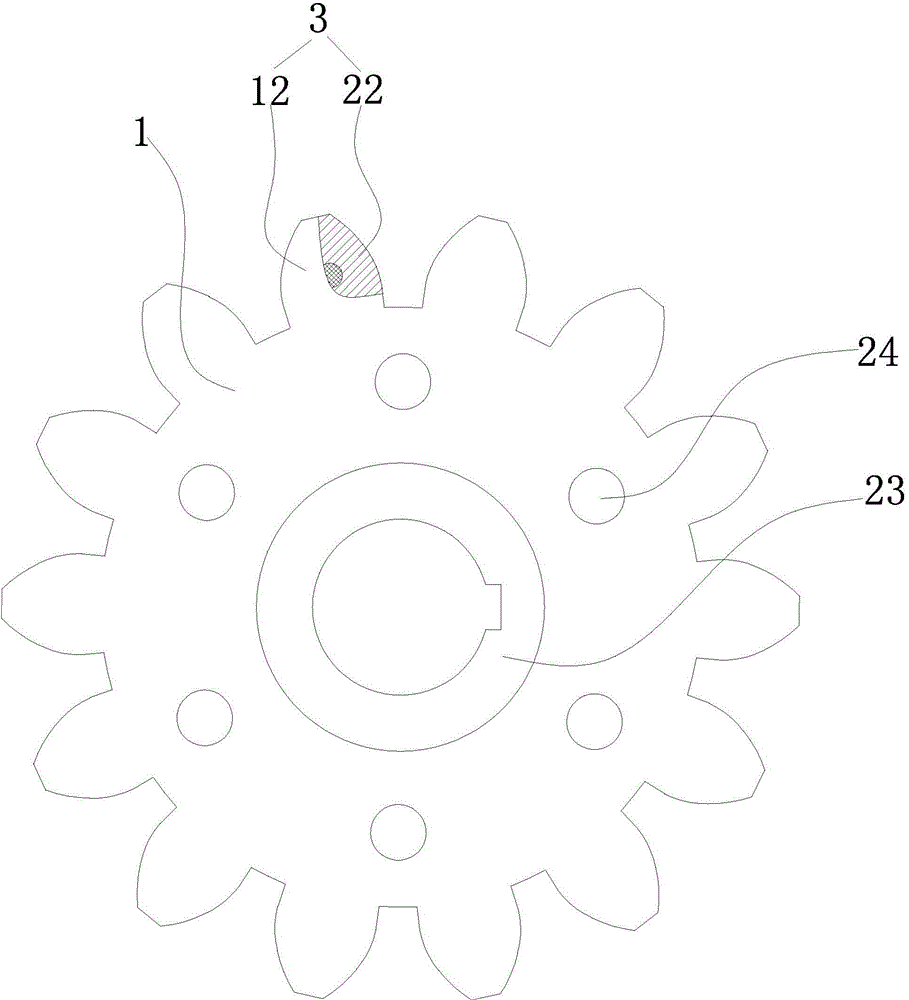

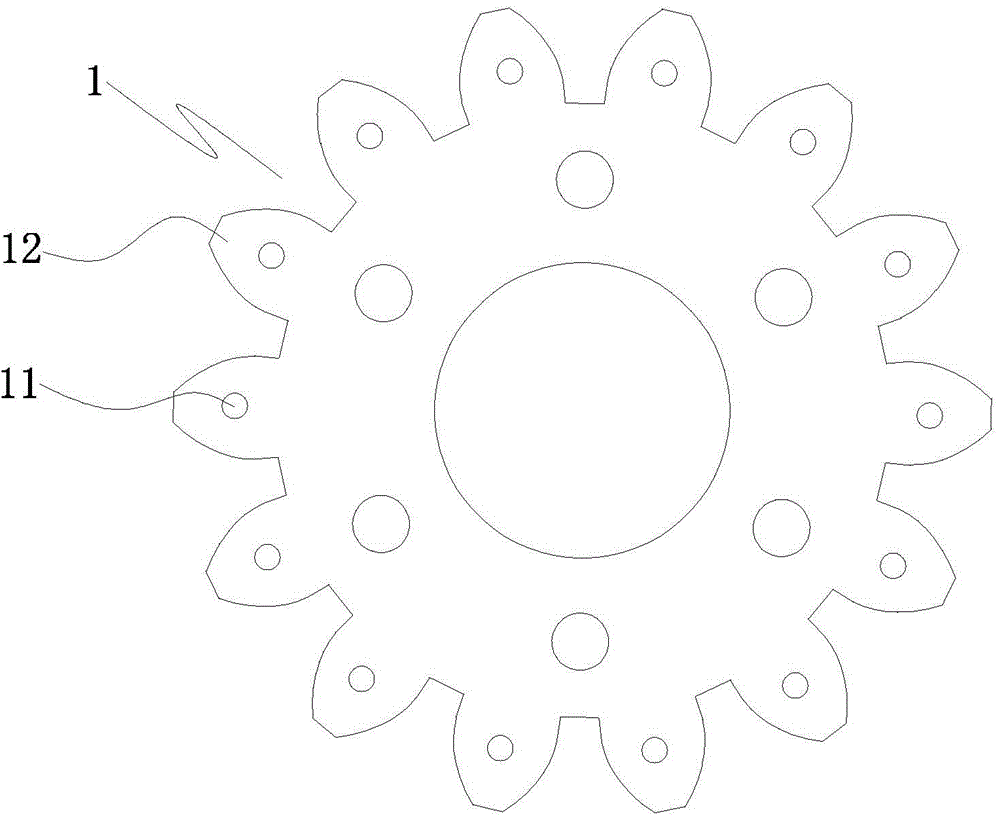

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a compound gear for an electric vehicle includes a gear body 1 made of plastic and a gear frame 2 made of metal embedded in the gear body. The gear body is made by injection molding. The material of the gear body is PVC or POM or PTFE or PA or nylon. The gear skeleton includes a shaft sleeve 23, an annular support end plate 21 arranged around the outer surface of the shaft sleeve and six first connecting columns 24 arranged on the support end. The inner hole of the shaft sleeve constitutes the gear shaft hole. The annular support end plate is perpendicular to the axis of the sleeve. The first connecting columns are parallel to the axis of the sleeve, and the first connecting columns are evenly distributed around the circumference of the sleeve. Several annular grooves 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com