Telescopic automatic leveling track system used for tunnel detection and using method of telescopic automatic leveling track system

An automatic leveling and telescopic technology, applied in measuring devices, surveying and navigation, instruments, etc., can solve problems such as inability to meet work needs, continuous measurement, cumbersome adjustments, etc., to save manpower, save space, and improve detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

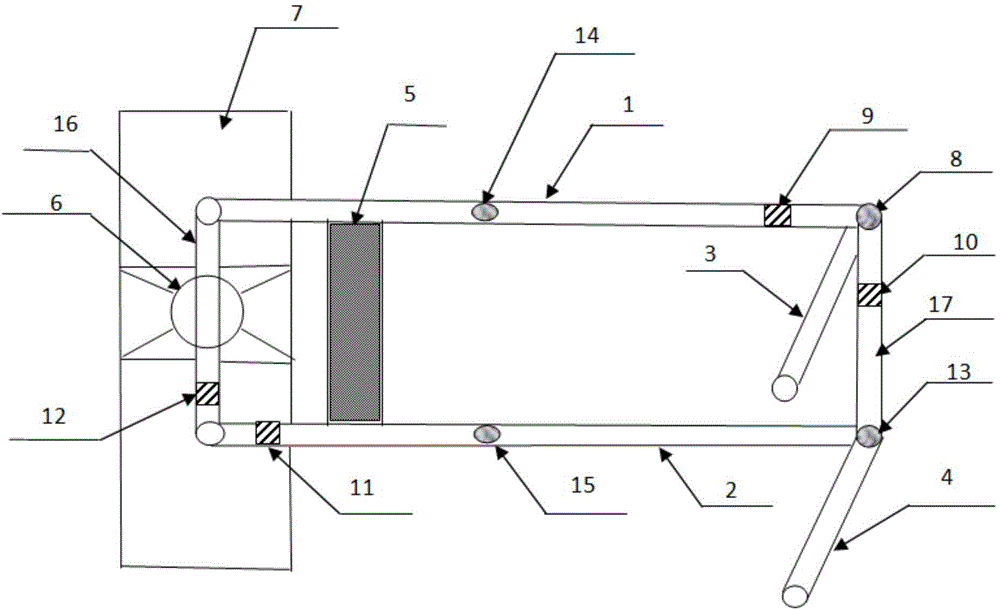

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

[0022] Such as figure 1 As shown, a telescopic self-leveling vehicle-mounted system for tunnel inspection, including longitudinal leveling rails 1, 2, first hydraulic support 3, first hydraulic support 4, instrument installation device 5, fixed transverse rail 16 spherical support 6, spherical support moving slot 7, first laser distance adjustment system 8, second laser distance adjustment system 13, third laser distance adjustment system 14, fourth laser distance adjustment system 15, first angle measurement A leveling system 9 , a second angle-measuring leveling system 10 , a third angle-measuring leveling system 11 , a fourth angle-measuring leveling system 12 , a first horizontal leveling track 16 , and a second horizontal leveling track 17 .

[0023] The retractable leveling track, that is, the first longitudinal leveling track 1 and the second longitudinal leveling trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com